TOOLS REQUIRED: Screwdriver, 11/32 wrench, socket or nut driver, a 7/16" wrench and 1/2"

wrench and socket, tape measure.

1. Layout the boom sections as shown on Dimension Sheet and assemble using (6) 8-32 x 1-3/4"

screws, locknuts. Tighten the nuts securely.

2. Use the Dimension Sheet as reference for installing the ELEMENT HALVES on to the ELEMENT

MOUNTING BLOCKS. For each element insert a 1/4 x 10” Element Support Rod from the drilled end.

Secure the rod / element assemblies to the element mounting blocks with (10) 8-32 x 1" screws and

locknuts. Install screws from bottom of blocks.

3. Mount the longest element (REFLECTOR) to the hole at the rear end of the boom using a 8-32 x

2" screw and locknut. Tighten securely.

4. Mount the DRIVEN ELEMENT next, threading the 8-32 x 2” screw into the 'T' MATCH BLOCK held

to the underside of the boom. Orient the match block with the “N” feed connector pointed to the front.

Mount the remaining DIRECTOR ELEMENTS. Carefully note lengths on Dimension Sheet:.

5. Thread the gold SEAL NUTS all the way onto the two small connectors on the 'T' match block with

the black neoprene side out. Then connect the balun connectors and tighten them GENTLY with a

7/16" end wrench. Now run the seal nuts up against the face of the balun connectors and tighten

them about 1/2 turn with a 1/2" end wrench. Secure coiled balun to boom with two nylon ties. The

balun does not need to be coiled. It can be unrolled and fastened to the boom to the front or rear.

6. Install two 8-32 x 1/4” Set screws into each SHORTING BAR. Then slide a SHORTING BAR onto

each DRIVEN ELEMENT HALF and position per the DIMENSION SHEET. Align rods and element

halves parallel and tighten the set screws with the 5/64" Allen wrench provided.

7. Install the feedline or a short section long enough to reach the boom center and on down the mast

and on past the the top of the tower. If the short section is used then the main feedline can be

attached at the time of installation on the tower. Tightening the Male 'N' connector carefully, and route

the cable forward on the boom, securing it with the cable ties provided. Stop about 24" in front of the

first director.

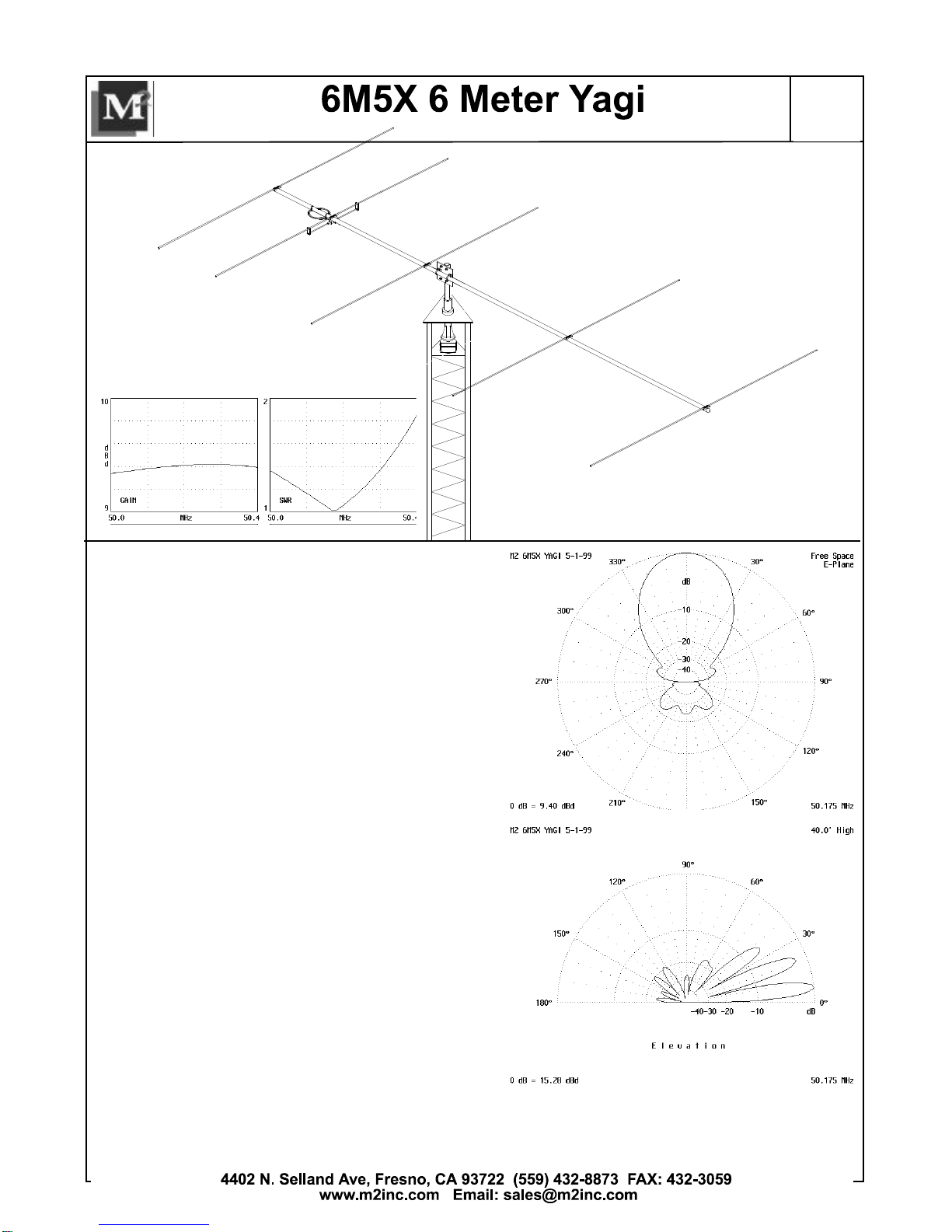

8. Mount the BOOM TO MAST PLATE perpendicular to elements at or near the physical balance

point of the antenna. Secure with the 1-1/2" U-bolts, 5/16” stainless steel lockwashers and nuts. Do

not over-tighten as severe boom distortion and subsequent weakening can occur. 2” U-bolts are

supplied for attaching the plate to your mast.

9. When the antenna is installed in position on the mast, the main feedline can be connected and

sealed at that time. REMEMBER to support the feedline at the antenna boom and on the mast.

Leave an adequate feedline loop for rotation around the tower. When stacking this antenna with other

HF models, maintain a minimum 5’ of separation; more if practical. Mount horizontally polarized VHF

and UHF antennas at least 40” above or below this antenna to minimize interaction.

10. INSTALLATION AND STACKING INFORMATION

A. A mast or cross boom that supports the antenna in the element plane must be non

conductive (fiberglass, etc). The feed line must also always exit the antenna at 90 degrees or

perpendicular to the elements for at least 60 inches.

B. To protect your investment in this high performance antenna, always use high quality coax and