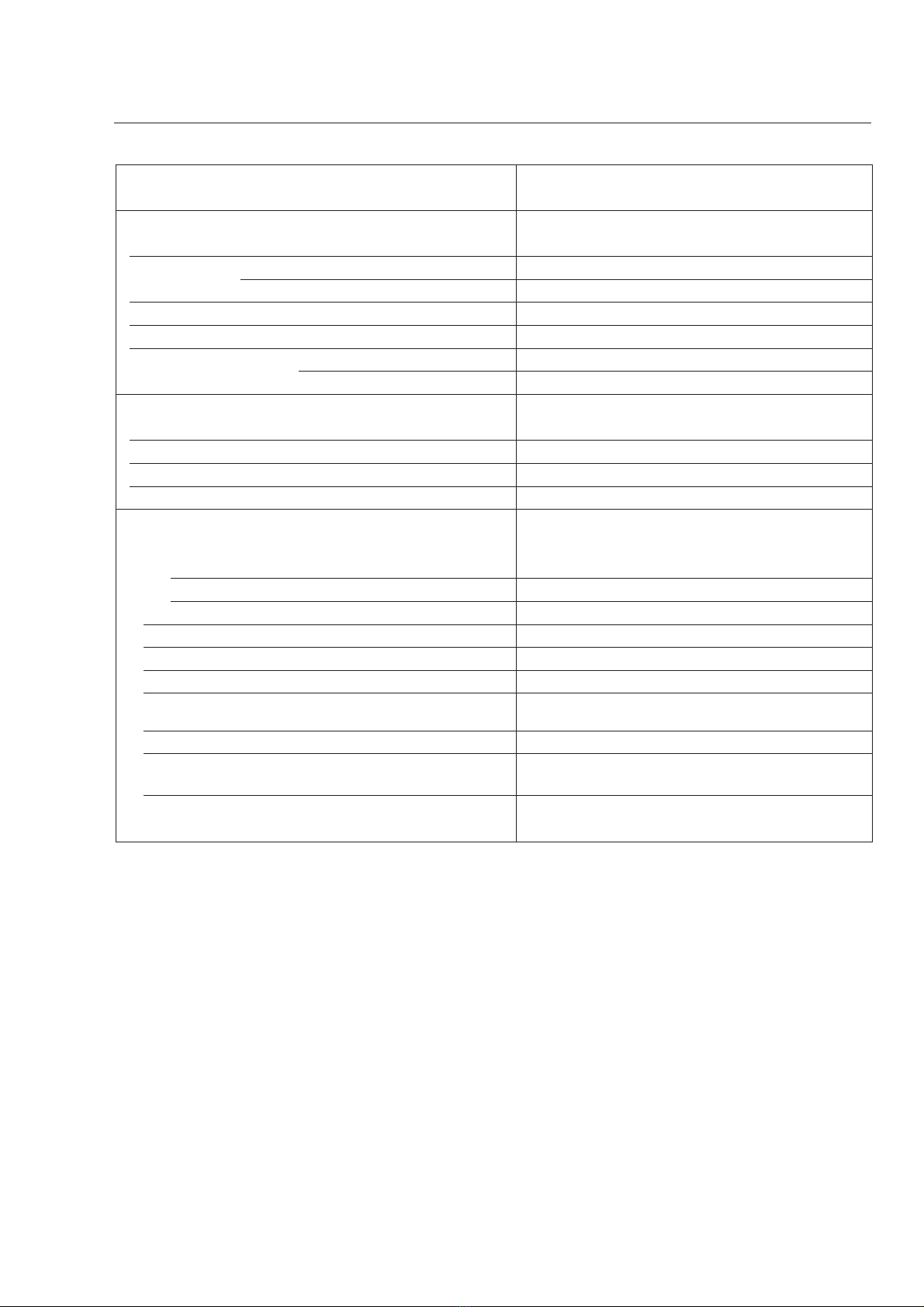

TABLE OF CONTENTS

PB-2520

EB252 1

Page Page

1 SERVICE INFORMATION.....................................2

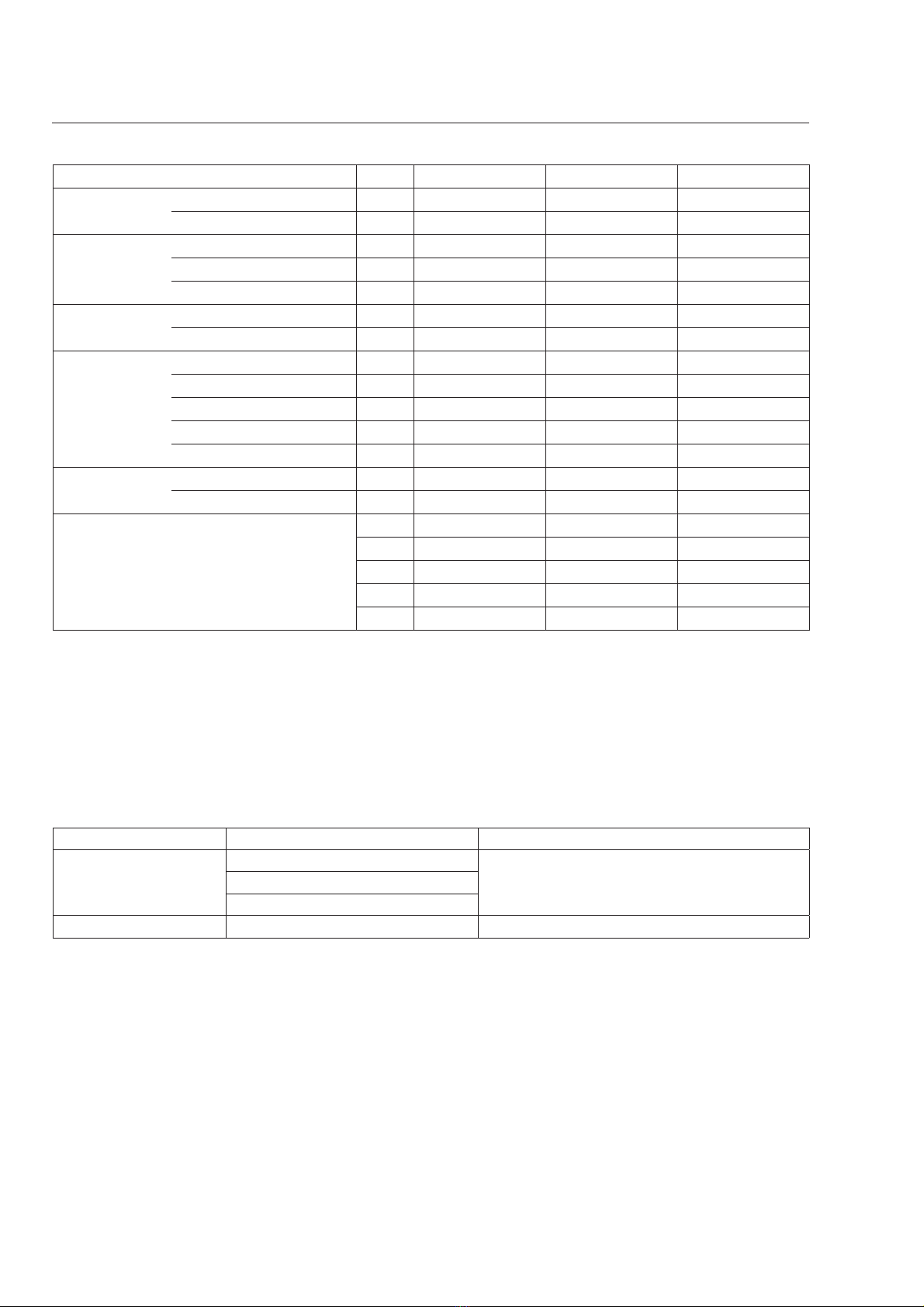

1-1 Speci¿cations...................................................2

1-2 Technical data ..................................................3

1-3 Torque limits.....................................................4

1-4 Special repairing materials...............................4

1-5 Service limits....................................................5

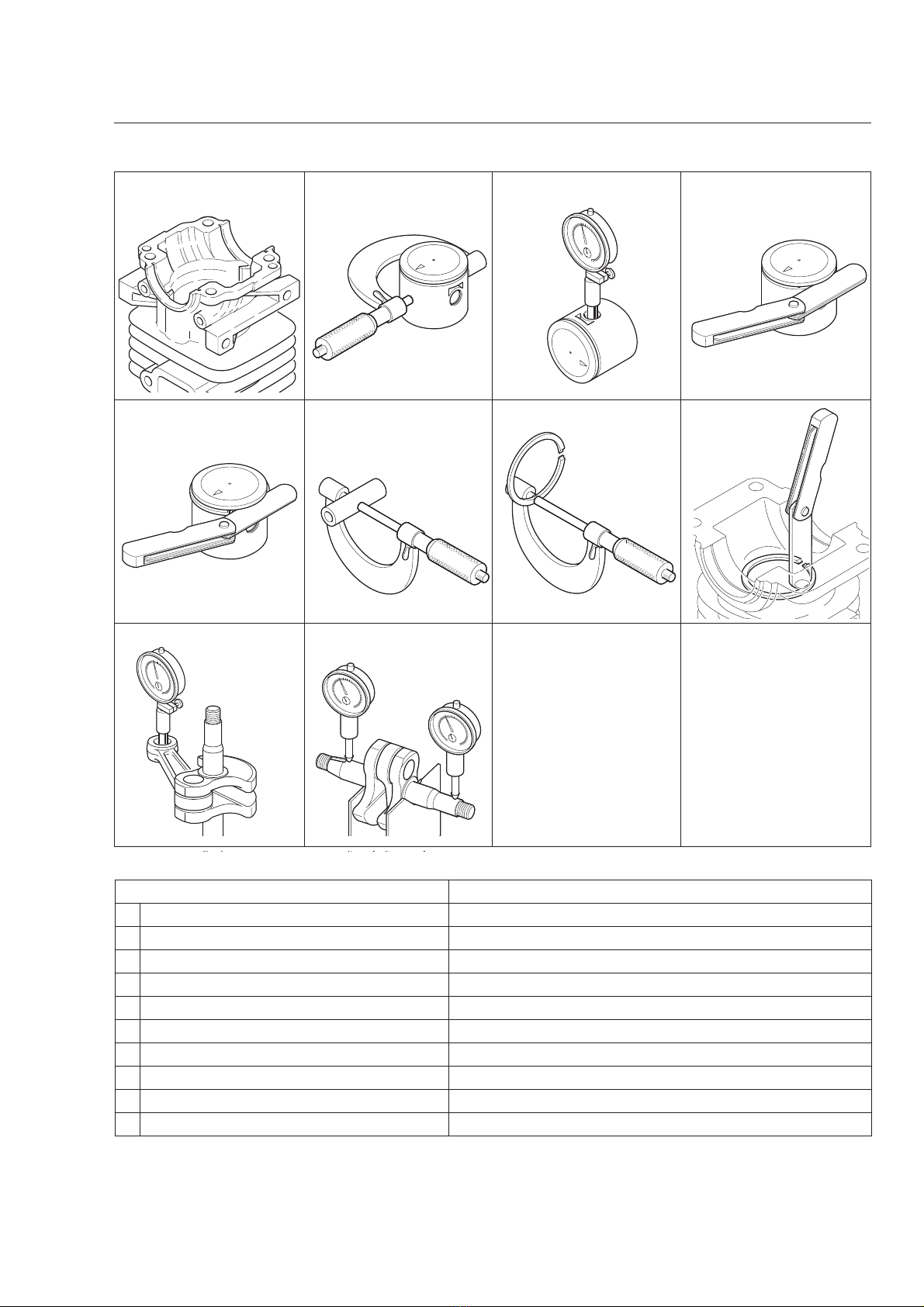

1-6 Special tools.....................................................6

2 STARTER SYSTEM ..............................................7

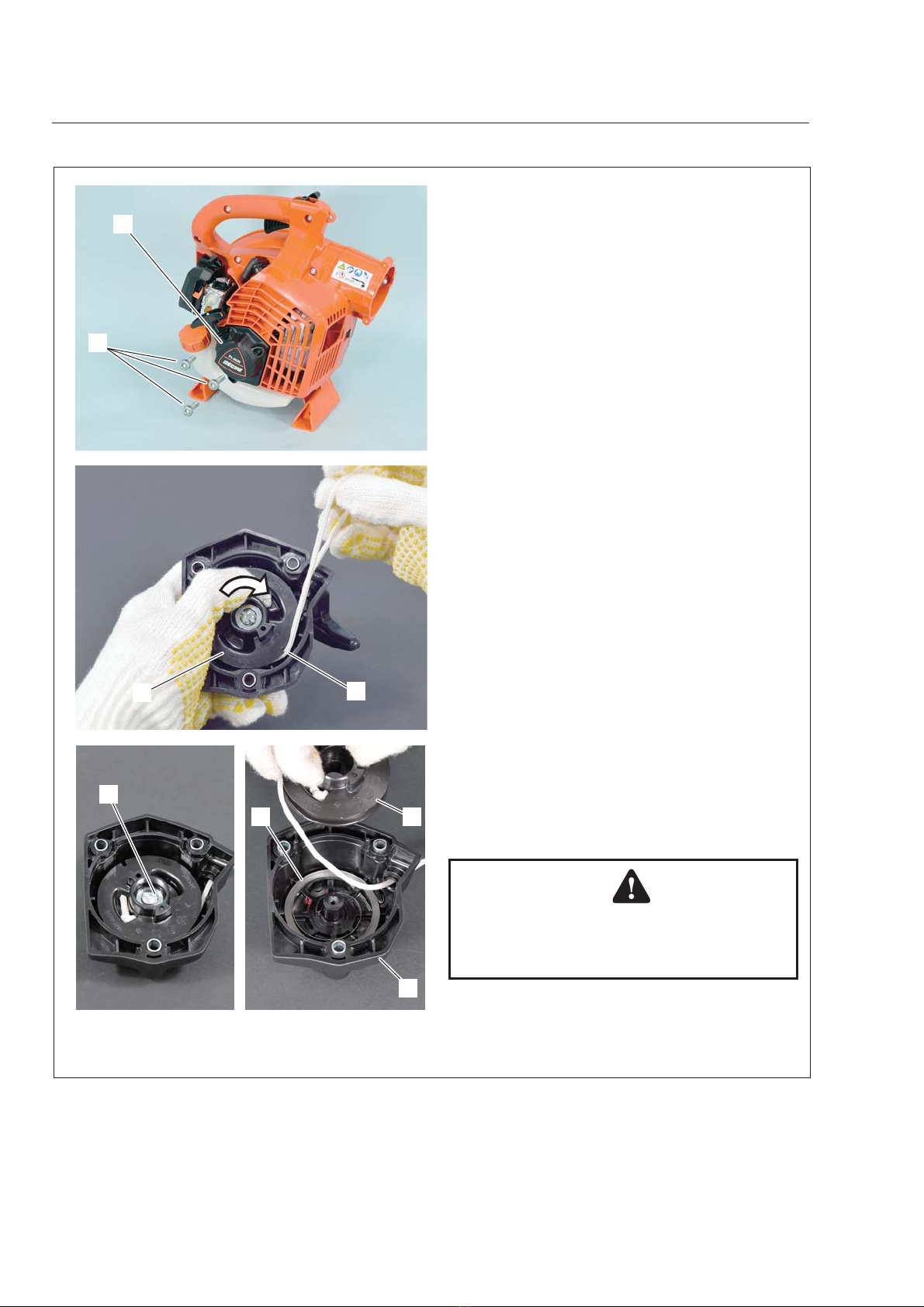

2-1 Disassembling starter assembly.......................8

2-2 Replacing starter rope......................................9

2-3 Installing rewind spring...................................10

2-4 Assembling starter..........................................11

2-5 Replacing starter pawl....................................12

3 BLOWER SYSTEM.............................................13

3-1 Inspecting fan and fan case ...........................14

3-2 Disassembling and assembling

fan and fan case.............................................14

4 IGNITION SYSTEM.............................................17

4-1 Troubleshooting guide....................................18

4-2 Testing spark..................................................19

4-3 Inspecting spark plug .....................................19

4-4 Replacing spark plug cap and coil..................20

4-5 Inspecting ignition module..............................21

4-6 Replacing ignition module..............................22

4-7 Setting pole shoe air gaps..............................24

4-8 Inspecting ignition switch................................24

4-9 Replacing ignition switch................................25

4-10 Inspecting Àywheel magnetic force ................26

4-11 Replacing Àywheel and key............................26

5 HANDLE AND CONTROL SYSTEM ..................28

5-1 Disassembling and assembling

handle and control parts.................................29

6 FUEL SYSTEM ...................................................30

6-1 Inspecting air ¿lter..........................................31

6-2 Inspecting fuel cap and fuel strainer...............31

6-3 Inspecting fuel tank and line...........................32

6-4 Inspecting and replacing tank vent.................33

6-5 Replacing fuel line, fuel return line,

tank vent line and grommet............................35

6-6 Adjusting carburetor.......................................36

6-6-1 General adjusting rules ..................................36

6-6-2 Initial setting Throttle adjust screw,

L mixture needle and H mixture needle..........37

6-6-3 Adjusting carburetor.......................................37

6-6-4 Inserting limiter plugs .....................................38

6-7 Testing carburetor...........................................39

6-8 Inspecting crankcase pulse passage .............40

6-9 Inspecting metering lever height ....................40

6-10 Inspecting inlet needle valve..........................41

6-11 Inspecting diaphragm.....................................41

6-12 Installing carburetor........................................42

7 ENGINE...............................................................43

7-1 Testing cylinder compression.........................44

7-2 Cleaning cooling air passages .......................44

7-3 Inspecting mufÀer and exhaust port...............45

7-4 Testing crankcase and cylinder sealings........46

7-5 Replacing oil seal...........................................47

7-6 Inspecting cylinder..........................................47

7-7 Inspecting piston and piston ring....................48

7-8 Disassembling crankcase...............................48

7-9 Replacing ball bearings..................................49

7-10 Assembling crankshaft and crankcase...........50

7-11 Installing piston...............................................50

7-12 Installing piston ring and cylinder...................51

7-13 Assembling engine assembly and

other parts......................................................52

8 MAINTENANCE GUIDE......................................53

8-1 Disassembly chart..........................................53

8-2 Troubleshooting guide....................................54

8-3 Service intervals.............................................56