3/4

CONTENTS

- Introduction

- Purpose

-Warnings and Cautions

- Directions

- Contents

1. Name of each part

1-1. Name of each part ......................................................................................................... 1

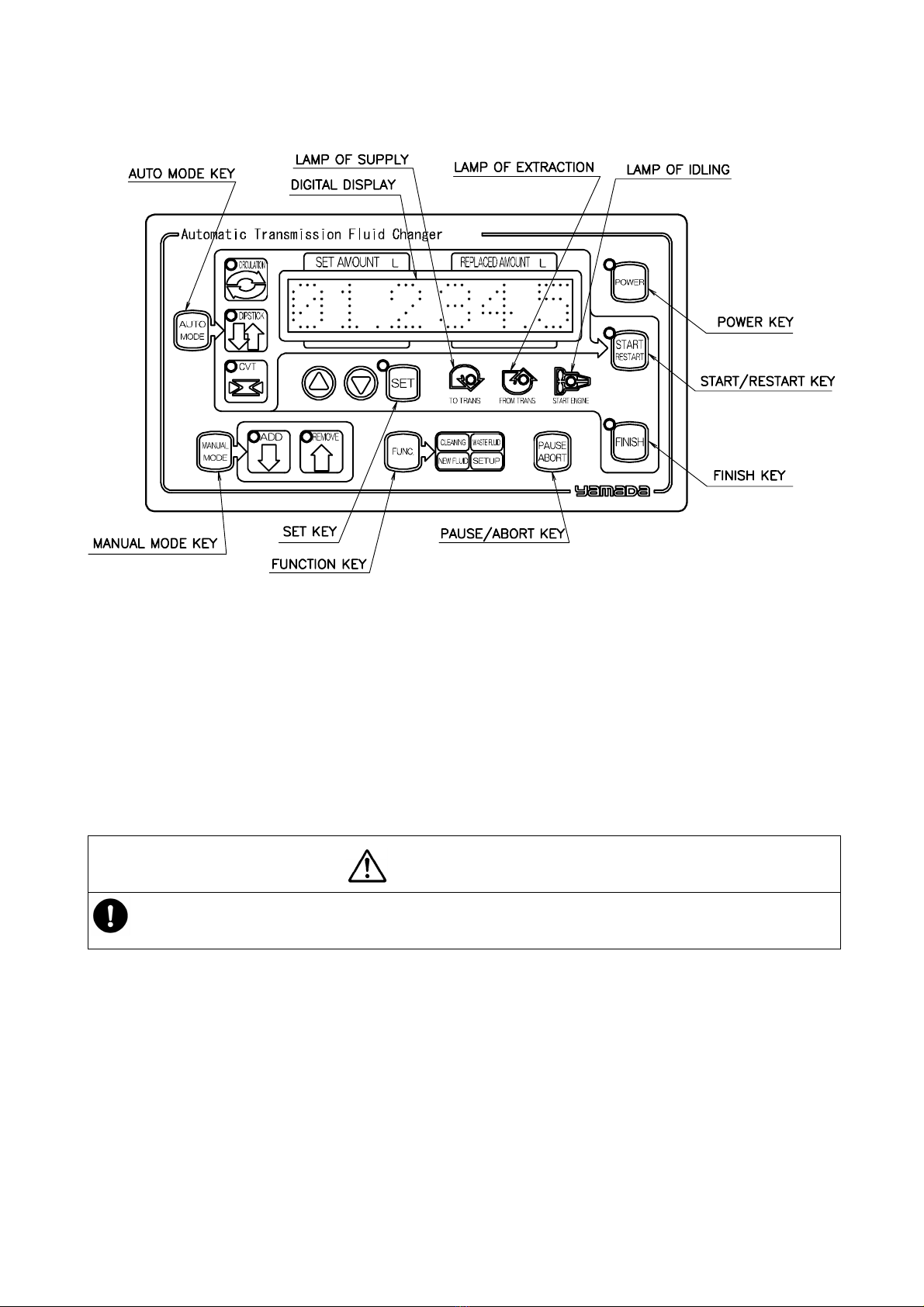

1-2. Operation panel ............................................................................................................. 2

1-3. Contents of package...................................................................................................... 2

2. Preparations before oil replacement

2-1. Setting a new oil pail ······································································································3

2-2. Taking out/Setting the wasted tank ················································································4

2-3. Connecting the flexible nozzle ·······················································································4

2-4.Setting up ························································································································5

3. How to use

3-1. Precautions ····················································································································6

3-2. Preparations for operation······························································································6

3-3. Inserting the flexible nozzle and notes ···········································································7

3-4. Car to be cared when inserting a nozzle for oil replacement·········································7

3-5.How to operate

3-5-1. Automatic mode······································································································8

■Circulation mode 8

■Dipstick (Alternate) mode ···························································································9

■CVT mode···················································································································10

3-5-2. Manual mode ··········································································································11

■Manual replacement of oil (Setting the amount of oil to be replaced) ························11

■Manual replacement of oil 2(manual) ·········································································12

3-5-3. Functions ················································································································13

■Cleaning······················································································································13

■Removing the waste oil·······························································································14

■Refilling new oil···········································································································15

■Setting·························································································································16

3-5-4. Other functions ·······································································································17

4. Maintenance and Inspection

4-1. Maintenance···················································································································19

4-2. Error Codes

■EO1【Oil removal error】······························································································20

■EO2【Insufficient flow rate for oil supply】【Insufficient flow rate for oil removal】········21

■EO3【Oil removal disabled】························································································22

■EO4【Oil removal error】······························································································23

■EO5【Setting error】·····································································································24

■EO7【Insufficient flow rate for oil removal】·································································25

■EO8【Oil removal disabled】························································································26

4-3. Troubleshooting··············································································································27

5. Main Dimensions···················································································································· 28

6. Specifications··························································································································· 29

7 .Parts list······································································································································· 30

7-1. Automatic transmission fluid changer(881082)······························································30

7-2. Cover assembly(854043) ·······························································································31

7-3. Flame assembly(854044)·······························································································32

7-4. Hose assembly(803619) ································································································33

7-5. Nozzle body assembly(804132)·····················································································34

7-6. Wasted oil tank assembly(804512) ················································································35

7-7. Base assembly(804514) ································································································36