D GENERAL

INFORMATION

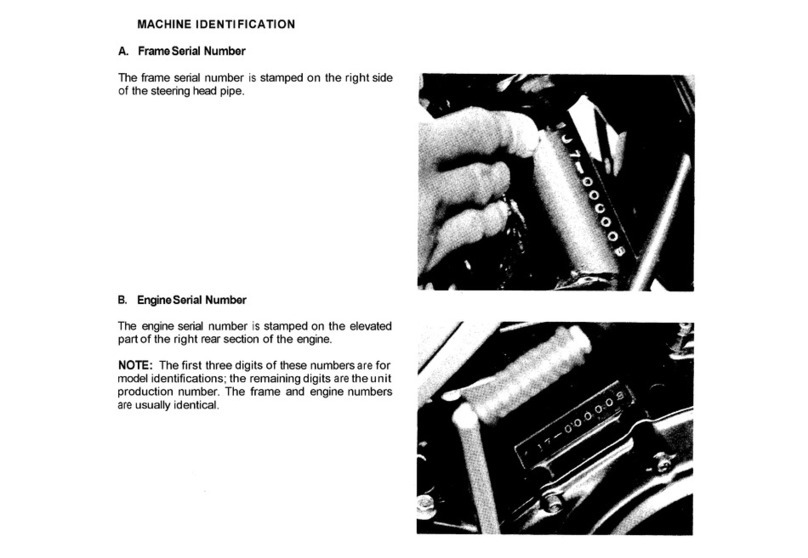

MACHINE

IDENTIFiCATION

....................................

1-1

Vehicle

Identification

Number

................................

1-1

Engine

Serial

Number

....................................

'"

.1-1

CONTROL

FUNCTIONS

...........................

.

.............

1-2

FUEL,

OIL

AND

COOLANT

.....................................

1-4

Fuel

.........................................................

1-4

Engine

Mixing

Oil

............................................

1-4

Transmission

Oil

...............................

.

.............

1-4

Coolant

Level

................................................

1-5

Coolant

Draining

.............................................

1-5

Replenishing

Coolant

.........................................

1-6

SAFETY

INFORMATION

.............

.

.........................

1-6

Ride

with

Care

and

Good

Judgement

........................

1-6

Wear

Protective

Clothing

....................................

1-7

Be

Careful

where

You

Ride

..................................

1-8

Modification

.................................................

1-8

RIDING

YOUR

TRI-MOTO

.....................................

1-9

Getting

to

Know

Your

Tri-Moto

..............................

1-9

Learning

to

Ride

Your

Tri-Moto

..............................

1-9

Turning

Your

Tri-Moto

.......................................

1-10

Climbing

Uphill

..............................................

1-11

Riding

Downhill

.............................................

1-12

Crossing

a

Slope

...........

.

.....................

. _

.........

1-12

Crossing

through

Shallow

Water

.............................

1-13

Riding

over

Rough

Terrain

...................................

1-13

Sliding

and

Skidding

....................................

.

....

1-13

What

to

Do

If

...............................................

1-14

PREOPERATION CHECKS

......................................

1-15

STARTING

AND

BREAK-IN

....................................

1-16

Starting

a

Cold

Engine

.......................................

1-16

Starting

a

Warm

Engine

......................................

1-16

Break-in

Procedures

..........................................

1-16

CLEANING

AND

STORAGE

.......................

.

............

1-17

Cleaning

.....................................................

1-17

Storage

......................................................

1-18