GX-500/GX-500VCD

GX-500/VCD

■SPECIFICATIONS

■AMPLIFIER SECTION

Minimum RMS Output Power per Channel

1kHz, 0.9% THD, 6Ω......................................80W + 80W

1kHz, 10% THD, 6Ω...................................100W + 100W

Input Sensitivity/Impedance

AUX/MD ........................................................ 200mV/47kΩ

Spectrum Analyzed Band .............................................5 band

(100Hz, 350Hz, 1kHz, 3.5kHz, 10kHz)

■VIDEO SECTION (GX-500VCD only)

Signal Level ..............................................................1Vp-p/75Ω

■TUNER SECTION

FM Tuning Range

U, C models.......................................... 87.5 to 107.9MHz

R, T models ........ 87.5 to 108.0MHz/87.50 to 108.00MHz

A, B, G, L model............................... 87.50 to 108.00MHz

AM Tuning Range

U, C models............................................ 530 to 1,710kHz

R, T models .................530 to 1,710kHz/531 to 1,611kHz

A, B, G, L models ................................... 531 to 1,611kHz

FM Usable Sensitivity (75Ω)

30dB S/N Quieting, Mono, 1kHz,

100% mod. R, U, C, L, T models .........1.5µV (14.8dBf)

DIN Mono, S/N 26dB (A, B, G only) ........................1.8µV

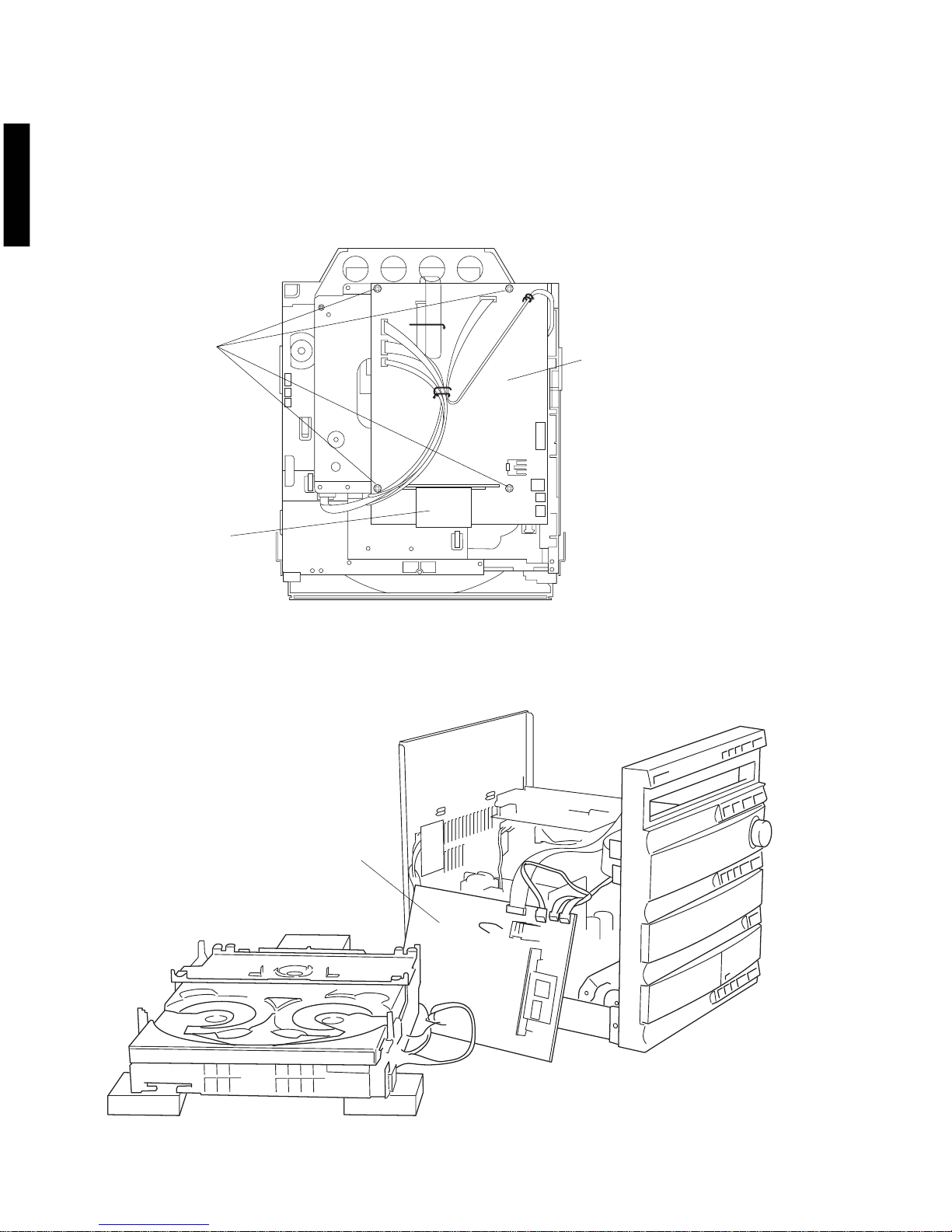

■CD CHANGER SECTION

Type .......................................... 3-Disc Carousel Auto-changer

Signal Readout......................................................Non-contact,

3-beam semi-conductor laser pick-up

D/A Converter............................................................. 1bit DAC

Filter ........................................8-time oversampling digital filter

Wow & Flutter ....................................................Unmeasurable

■TAPE DECK SECTION

Type ..................................................................... Auto Reverse

4-Track 2-Channel playback/recording stereo Cassette Deck

Heads

REC/PB..................................................... Hard permalloy

Erase................................................... Double Gap Ferrite

Motors

Main ......................................................... DC servo motor

Tray Loading ...................................................... DC motor

Wow & Flutter

W.PEAK ................................................................. ±0.19%

W.RMS ..................................................................... 0.09%

Frequency Response (–20dB)

Type I/Normal tape........................ 50 to 15,000Hz ±3dB

Type II/High (CrO2) tape ............... 50 to 16,000Hz ±3dB

S/N Ratio

NR off.........................................................................58dB

Dolby B NR on...........................................................66dB

■SPEAKER SECTION (NX-GX500)

Type ................................................. 3-Way Bass-reflex Design

(Magnetic-Shielding Type)

Speakers .................................................. 13cm (5-1/8”) woofer

5cm (1-15/16”) tweeter

2cm (13/16”) super tweeter

Frequency Range............................................. 60 to 20,000Hz

Maximum Input ................................................................240W

Impedance ............................................................................ 6Ω

Sound Pressure Level....................87dB/1m • 2.45V (1W/6Ω)

■GENERAL

Power Supply

U, C models............................................... AC120V, 60Hz

A model...................................................... AC240V, 50Hz

B, G, L models........................................... AC230V, 50Hz

R, T models ..................... AC110/120/220/240V, 60/50Hz

Power Consumption........................................................140W

(approx. 1W when set to the standby mode)

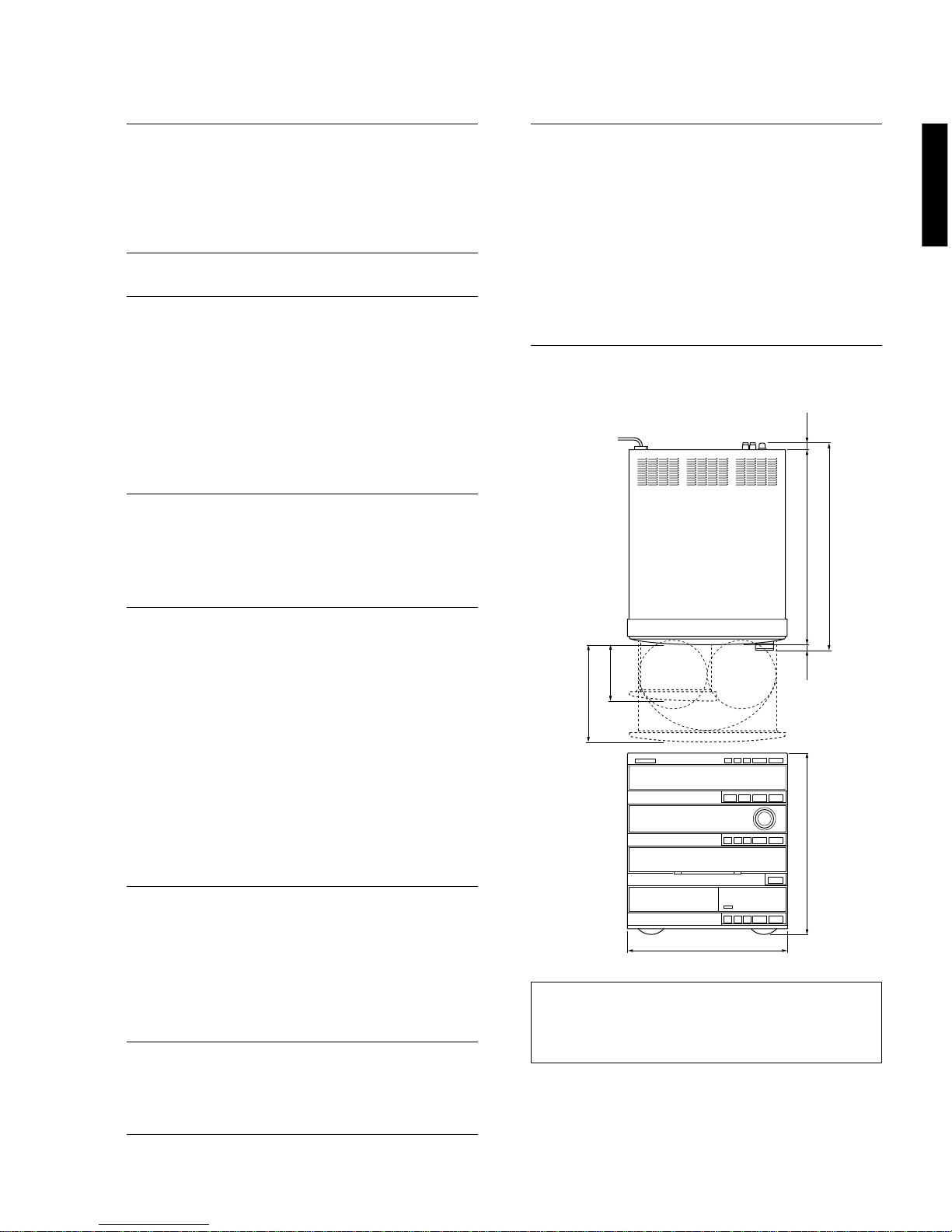

Dimensions (W X H X D)

GX-500............................................. 280 X 320 X 364mm

(11” X 12-5/8” X 14-5/16”)

NX-GX500........................................ 200 X 320 X 218mm

(7-7/8” X 12-5/8” X 8-9/16”)

Weight

GX-500............................................. 10.5kg (23 lbs. 2 oz)

NX-GX500....................................3.8kg (8 lbs. 6 oz)/each

Accessories ............................................ AM loop antenna X 1

Indoor FM antenna X 1

Remote Control Transmitter X 1

Battery (size “AA”, R06) X 2

Speaker Cord X 2

* Specifications subject to change without notice.

* Manufactured under license from Dolby Laboratories Li-

censing Corporation. “DOLBY” and the double-D symbol

Vare trademarks of Dolby Laboratories Licensing Cor-

poration.

U ...................U.S.A. model G ............ European model

C ............. Canadian model R ............... General model

A ............Australian model L ............ Singapore model

B ..................British model T....................China model

6

343(13-1/2") 12

(1/2")

9

(3/8") 364(14-5/16")

100

(3-15/16")

172(6-3/4")

280(11")

320(12-5/8")