PARTS I.IST

Your Tiller isRight Hand IA.H.t or Left Hand(L,H.I as You Operate Machine.

NOTE: Unlessothe,wis~ specified parts listed are usedon all Models.

REF

NO.

I

,

:2

2

PART No.

40~:!.3

42050

403~5

4;20..49

61832

61836

61818

61834

61838

61829

6183::1

61837

618~1

6'835

1$41-5

1546.29

15Q9-91

1542-8

41:;}'42

1632.142

40299

t652-90

~O1.135

0115.33-

42340

40060

42122

40048

40164

40163

40023

20644

20612

40099

1547.42-

20301

40250

1663.23

40305

4Q~96

40149

, 42:3$0

401$~

501;139

4~1'pO

41133

403'18

61814

1534.20

40303

4Qo25

40317

42;3;51

4Q893

42331

16'01).439

1601).440

'606-441

22:517

4~2!49

42250

42251

6t839

61841

161t3.317

164~.42

42334

QTY

B

8

8

8

T

,

2

,

1

2

,

,

1

1

3

2

T6

16

16

T

2

2

1

1

1

1

2

1

1

2

2

1

1

5

5

6

7

8

A

10

11

12

13

1&

16

17

18

19

20

21

22

23

24

25

26

27

28

29.

30

313.2

33

34

~5

36.

3'1

38

39

40

41

42

43

44

45

46

47

48

49

50

50

50

51

62

52

S2

53

53

54

55

56

1

1

2

1

2

1

8

2

12

5

1

OE~CRIP-rtON

Tine, 6010 (L,H,) 5/,6x 1~1/4 It 14" dia. (5020.1.5030-1 only)

Tine, Bol6 \L.H.j'13/6.4 x 1:1/4 x 14" dia (5010.1 only)

Til~e, BOlo (R.H.I 5/'G'~'1,'f4'11 14" die, 15020-1,5030-1 only)

Tine, BOlO !A,ti:f '.13164X 1.1(4 x 14" dia. (5010-1 only)

Assy, SpoOl, Outside~/Tln_s'iL,H,1 (5010-1 o'nlvt

Assv., Spool. OutsidewfTir)es:ll.H.) (5020.1.5030-1 onlv)

Assy..SpObl, O'J!side: :'

Assy.,SpOOI,ln$idew/TinesiL,H'.) (50'0.1 only>

A,SSy', Spool, Insidew/Tinos !L,H.) (6020-1.5030.' only)

AUy.. Spool. Inside

AMY.. S"OOI,I"$;<11o wjTines l~H.J (5010.1 only)

A$SY.,SpoQJ, Insi~ w/Tinec' (A.H.) (6Q20.1, 50.30-1 only)

A$Sy,'SpOOI;O\.ltside w/Tines (A,H,) 15010-' ()nly)

A$$V.,SJ)oOI, Outside w/Tines (R.til (5020-1,5030-' ontv~

HaIrpIn totter, 3/;12 die,

P\N;Clevis, 3/8 dia )(2"

Bolt; Hex Head; ~/a-16 It,., /4

Lockw.~er, 3/8 ISptlng Type)

Ntj!, ttex {ES\..OK)3/~:;6

Shaft, Tine, 1" dia

Oil SRel, Do\.lble Lip

Se~ring, Nefl9le. "'" 1-1/4 x 1" L.'

G~ar H!>usi~g

AS$Y., Transmission, Cumplete

Plu9, Pipe. 1/8 NPT.F' (Spetiel Vent,d}

PII!~, Pipe, 1/4 NPrf'

Nut,tie" Flexlock, ThIn, 5/16-18

P,in,Spring, 1/4 die. x 1"

Bearing, Thrust

Washer, Thrust

Bearing, Ball

Worm, 3T. (RH:I

WormGear,~8T. (R.H,)

Spacer, Worm

Pin, Grooved. 5/16 die. ~ 2"

Shaft, Pullev

Pin, Spring, 1/8dta. 1\3/8

Gasket, Geer Housing

Bolt, Hex H$ad; 5116-18 x 1.1/2 (NY LOCK)

Lid, Gear HousIng (includes Bushing Aef, No. 4p')

LOCkw~er" 5/16

Bo"t, Hex Head ((1rade 5) 5/16-18 x 4"

Nut, Hax lack (2.w~y) 5{16-18

Bolt, Hex He.d, 5/16-18 !t2"

Bolt. Carriage. 5/1&18 x 3/4

8~lt,"Cartiag., 5i1~.i8)( 1"

Spring, Exten,ioh

Assy., enQin~ 8,se

Nut, Hex, 5/1£':18 ",:'

!:"xtension $iock

Seal,OII

6ushiflQ, Qilltt, .191 ".817 x ;.1/8'"

Bolt, Hex Head-{Gr8d~ ~t 5/1ti~18 x 1~112

Bolt; Hex Head,5/16.18 ~ 1.5/8

Decal, Tine Shield C

Det;81, Mod~1 No. (5Q10-1 only)

Decal, Mod~.tNo~ (5020.10;11fyl :' ,

D~I.. Model 'No. (503~.1 onlyl :

Cover, Tine Shield

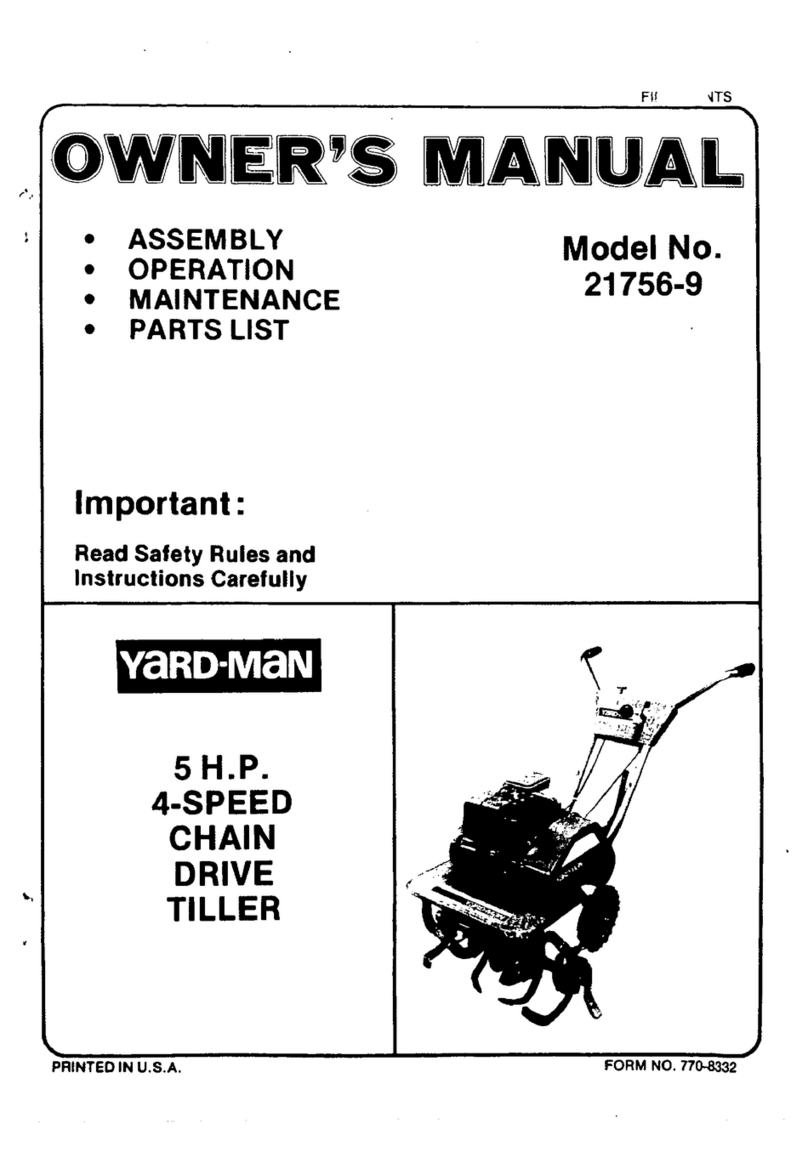

Er'lginl:;3 H:P.(6010.1 anivl

/ET)gine, 4 H.P,(50~9-1 q"WI

Engil'le. 5 HP.i$O3Q.1 only!

A.ssy., Pulley Colier Support ~racket(502o.1. 5030-' only)

A5$V, Pulley COll~!' Bracket ('5010-1 only)

Decal, Belt Adjustment Warning

Knob, Throttle Cohtrtll (5020-1.5030-' onlyl

Decal, Engine {5010., only)

10