Yardline LYNWOOD GABLE User manual

Other Yardline Garden House manuals

Popular Garden House manuals by other brands

Yardmaster

Yardmaster 66 ZGEY Assembly instructions

Mercia Garden Products

Mercia Garden Products 0628LOG181-V4 manual

Lemeks

Lemeks Palmako PA120-5930-6 Assembly, installation and maintenance manual

Rion

Rion Hobby Gardener Assembly instructions

Select

Select ISAAC E9682 Assembly manual

Palmako

Palmako Saale installation manual

Palmako

Palmako Roger FR44-5953-2 installation manual

Lemeks

Lemeks Palmako Grace PM56-4529 Assembly, installation and maintenance manual

Mercia Garden Products

Mercia Garden Products 03WES0808-V1 General instructions

Mercia Garden Products

Mercia Garden Products 03DTSHHP1206HGD4MW-V1 General instructions

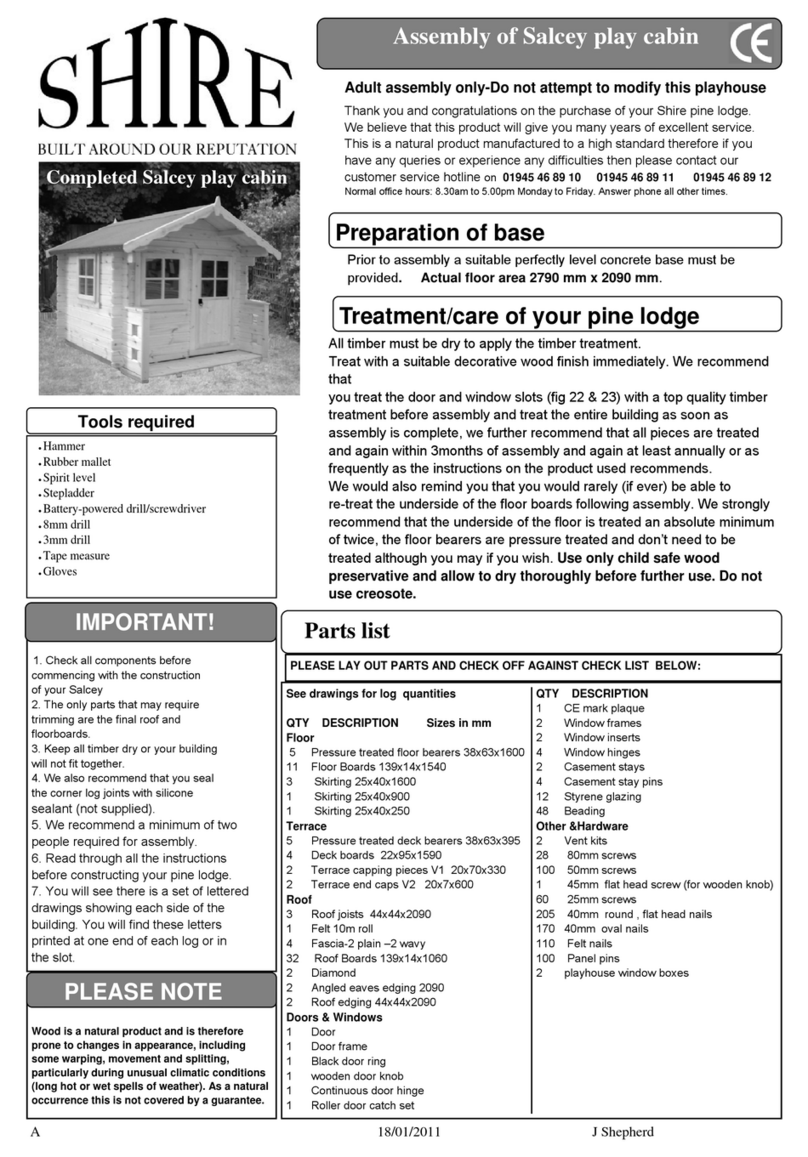

Shire

Shire Salcey Assembly

Pergola kits USA

Pergola kits USA PREMIUM VINYL PAVILION Assembly manual

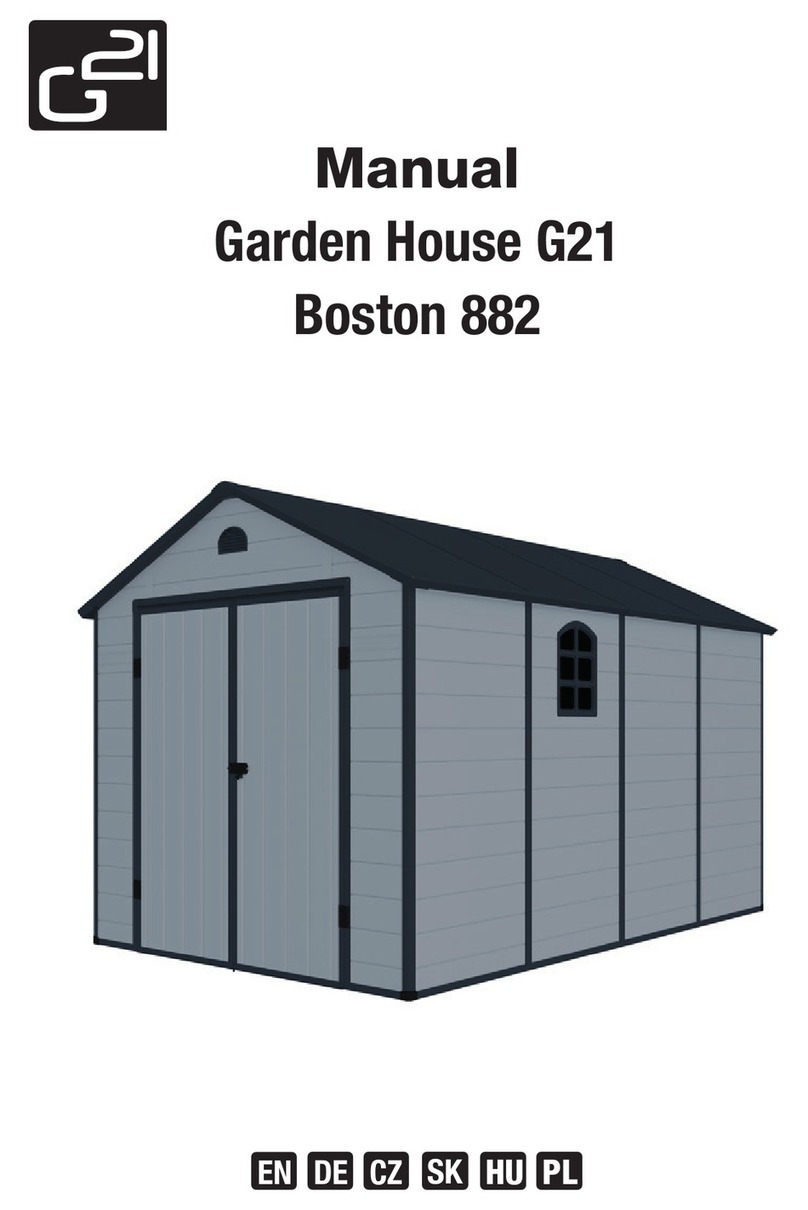

G21

G21 Boston 882 manual

Mercia Garden Products

Mercia Garden Products 05DTMBPN0503DD-V1 Assembly instructions

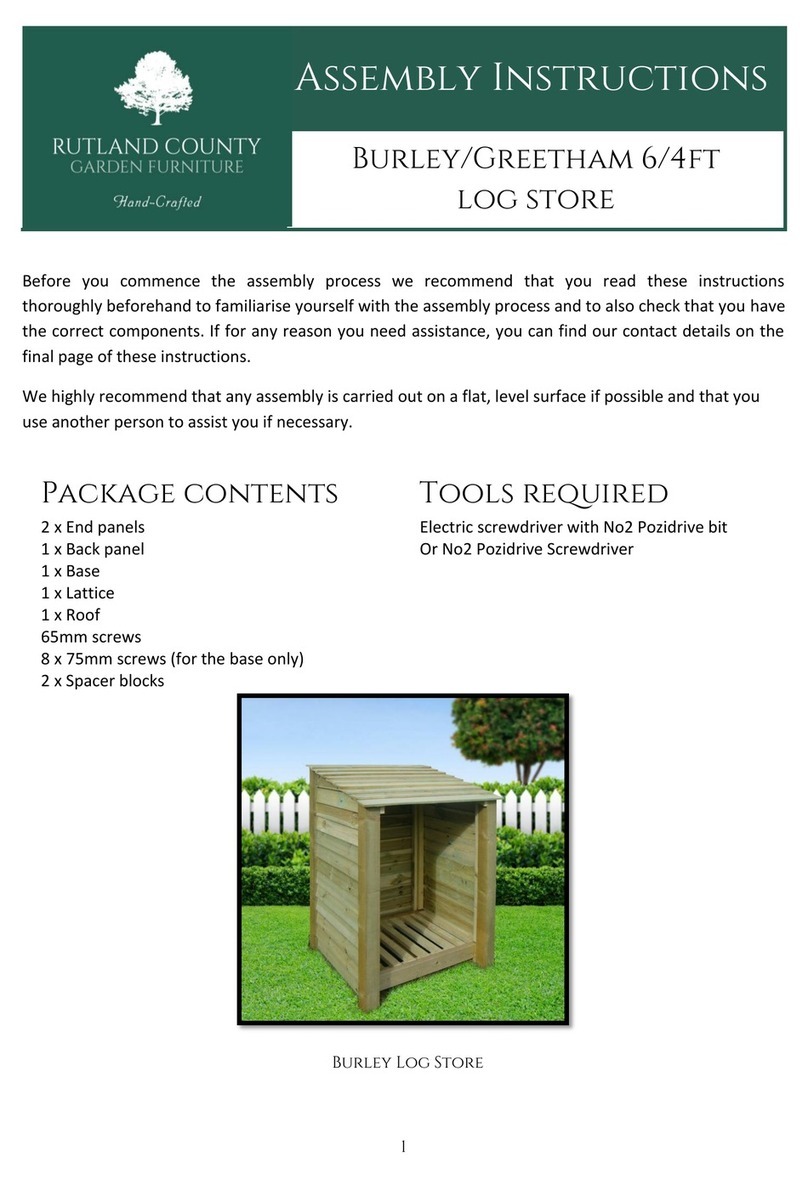

Rutland County

Rutland County Burley 6ft Assembly instructions

Palmako

Palmako Roger 27,7 installation manual

Mercia Garden Products

Mercia Garden Products 01PTOSBA0306DDNW-V1 General instructions

Gartenhaus-King

Gartenhaus-King Valery manual