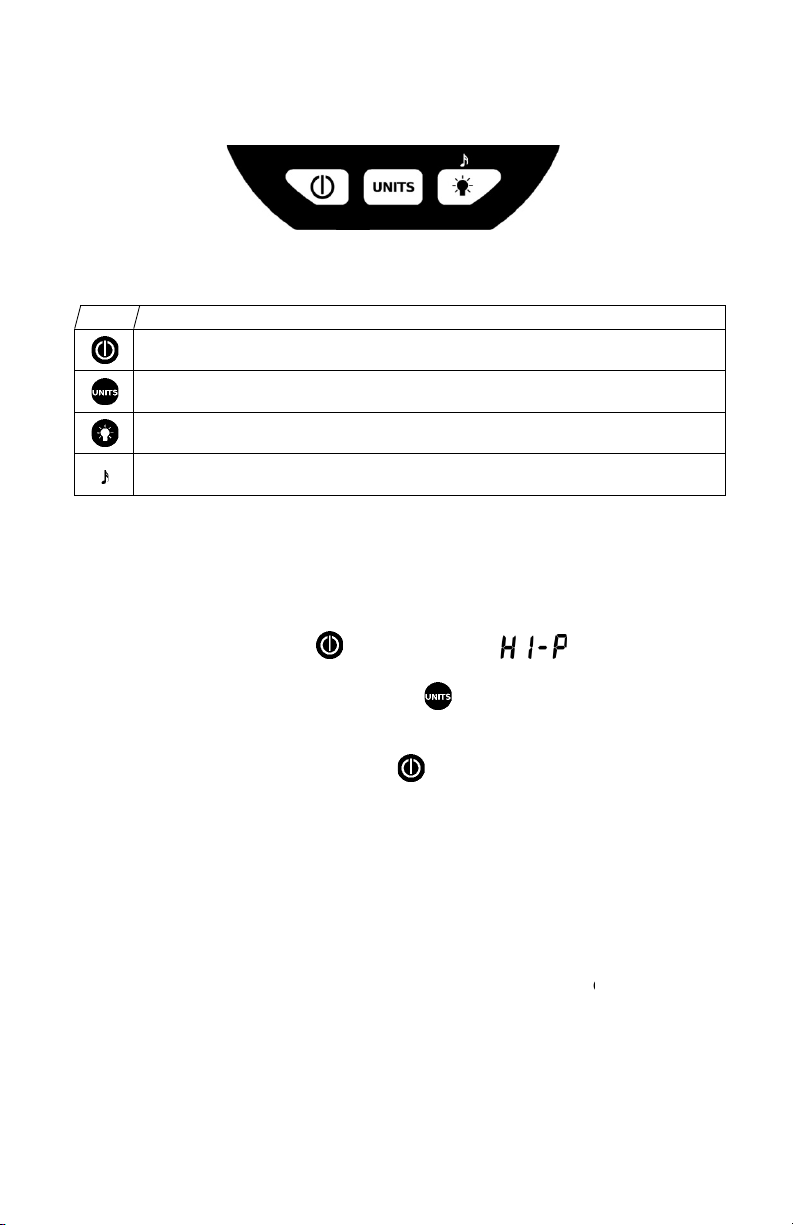

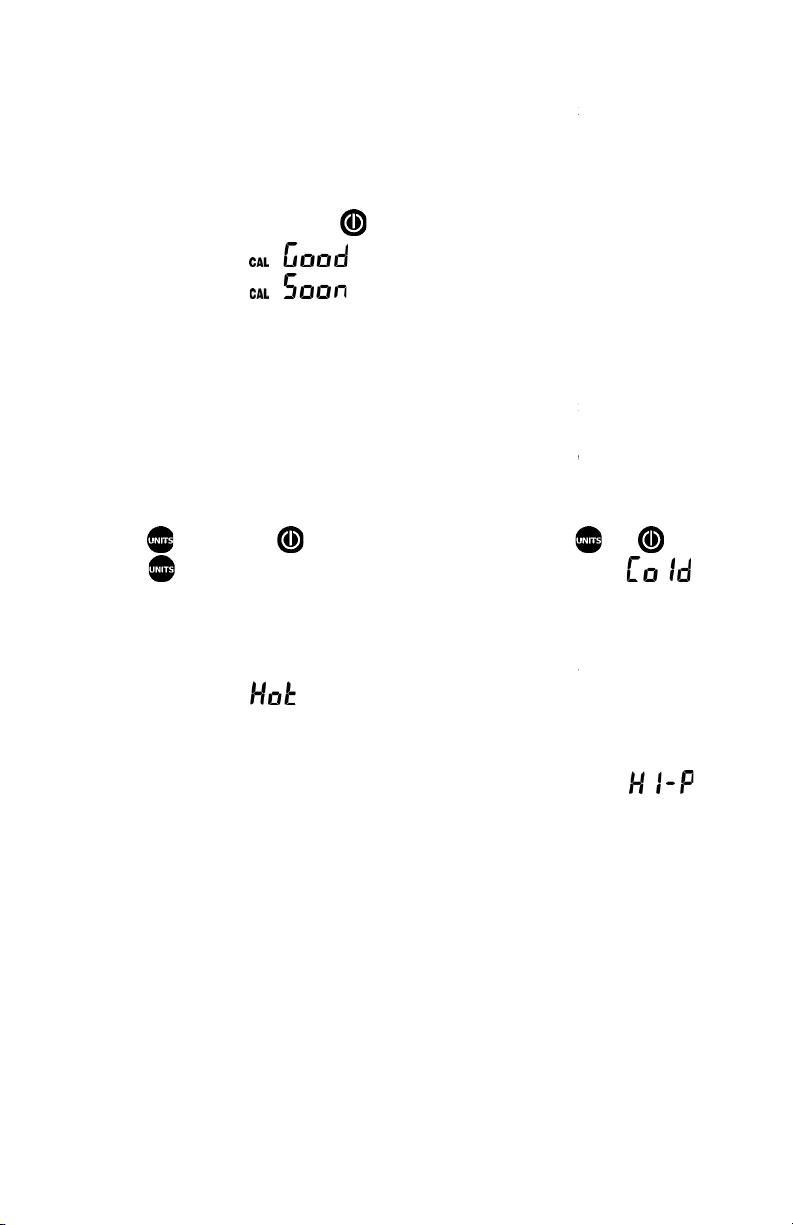

BACKLIGHT

To activate the Backlight temporarily, press once. The indica

tor on the display will flash,

and the backlight will turn off automatically after 1 minute. To activate the Backlight permanently,

press again. The

indicator on the display will show solid. Turn off the backlight by pressing

repeatedly until the

indicator turns off.During Sleep Mode,the backlight will turn off to help

conserve battery power, but will turn on again automatically upon resumption of normal operation if it

was previously set in the permanent-on mode.

SOUND

The EVac I has an i

nternal speaker that will emit a beepfor each valid key press, and also functions

as an alarm in the Calibration mode (see the Calibration section below). It will also beep every 5

minutes in Sleep Mode. For silent operation, the sound can be muted by p

key. The Calibration mode alarm is not affected by the mute status. The

display indicates thatthe sound is on (not muted).

SWIVEL HOOK

The EVac I’s removable stainless steel swivel hook enables hanging o

f the gauge and will allow it to

swivel freely in any direction. The gauge may be operated with or without the hook attached. When

fastening the hookto the gauge, turn it finger tight only. Use of a tool totighten the hook may result in

damageto the EVac I case.

MAINTENANCE

The EVac I

should provide many years of service with no maintenance required. When not in use, the

dust cap should remain in place over the sensor port. Clean the plastic enclosure with a damp (not

wet) rag. Mild detergent is acce

ptable, but use no solvents. Take care not to expose the vacuum

sensor to oil. If the Oil Sensor (described above) indicates a contaminated sensor, follow the Sensor

Cleaning Procedure below.

CLEANING THE VACUUM SENSOR

If the vacuum sensor becomes cont

aminated with oil (as indicated by the Oil Sensor), carefully follow

this procedure:

1. Turn the EVac I power off.

2. Shake the gauge to remove any large quantities of oil from the sensor.

3. Apply a few drops of rubbing alcohol inside the sensor vacuum port. (DO

OBJECT INTO THE PORT, AS THIS WILL PERMANENTLY DAMAGE THE SENSOR

4. Place yourfinger over the port and shake for a few moments.

5. Remove your finger and shake out the alcohol.

6. Repeat steps (3) – (5) at least three times.

7. Allow the sensor to a

ir dry over at least an hour, or pull a vacuum on the sensor to clean it more

quickly.

8.

Replace the battery andturn on the gauge. The Oil Indicator should be off. If it is still on, repeat

the cleaning procedure.

9. If full accuracy is desired, perform a c

alibration cycle as detailed in the Calibration section below.

Note

: It is important to remove all alcohol vapors from the sensor, eitherthrough air

vacuum. Any remaining vapors will cause an incorrect vacuum reading.

tor on the display will flash,

and the backlight will turn off automatically after 1 minute. To activate the Backlight permanently,

indicator on the display will show solid. Turn off the backlight by pressing

indicator turns off.During Sleep Mode,the backlight will turn off to help

conserve battery power, but will turn on again automatically upon resumption of normal operation if it

nternal speaker that will emit a beepfor each valid key press, and also functions

as an alarm in the Calibration mode (see the Calibration section below). It will also beep every 5

f the gauge and will allow it to

swivel freely in any direction. The gauge may be operated with or without the hook attached. When

fastening the hookto the gauge, turn it finger tight only. Use of a tool totighten the hook may result in

should provide many years of service with no maintenance required. When not in use, the

dust cap should remain in place over the sensor port. Clean the plastic enclosure with a damp (not

ptable, but use no solvents. Take care not to expose the vacuum

sensor to oil. If the Oil Sensor (described above) indicates a contaminated sensor, follow the Sensor

aminated with oil (as indicated by the Oil Sensor), carefully follow

NOT INSERT ANY

OBJECT INTO THE PORT, AS THIS WILL PERMANENTLY DAMAGE THE SENSOR

).

ir dry over at least an hour, or pull a vacuum on the sensor to clean it more

Replace the battery andturn on the gauge. The Oil Indicator should be off. If it is still on, repeat

alibration cycle as detailed in the Calibration section below.

: It is important to remove all alcohol vapors from the sensor, eitherthrough air

-drying or via