Page3

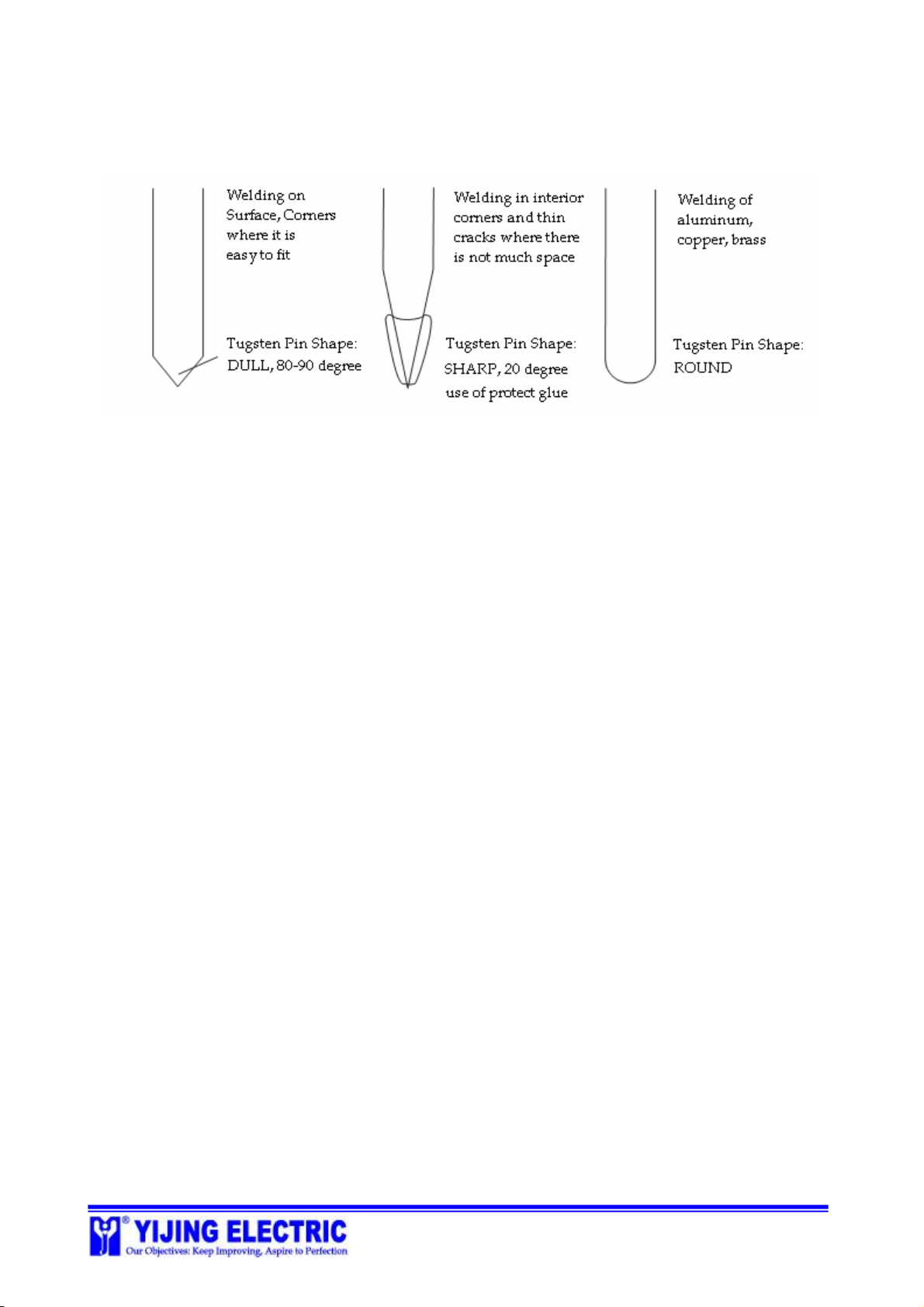

TungstenTip

Intheweldingtorch,thereisamountedtip, whichismadeoftungsten.Thedesignofthetip

varies as theweldingtask changes. Plssee thefollowing pictures.

*NOTE:

1.Dull pinisthemoststableshapeoftungstenpin.We suggesttheuseofthisshapeasmuchas

possible.

2.Ifthedull pincannotfit,trythesharppin.

3. Theprotectglueisaspecial-madeheat-resistanceglue.Itcanprotectthetungstenpinand

prolong itsservicelife.

4. Theroundpinbestpreventpin-stuck.Itishighly recommendedfor welding ofaluminum,

copperandbrass.

5. Normally,weusepinsof 1.6mm.Ifrepairinglargeoutput,changethepinto 2.0mm, to

prolong itsservicelife.

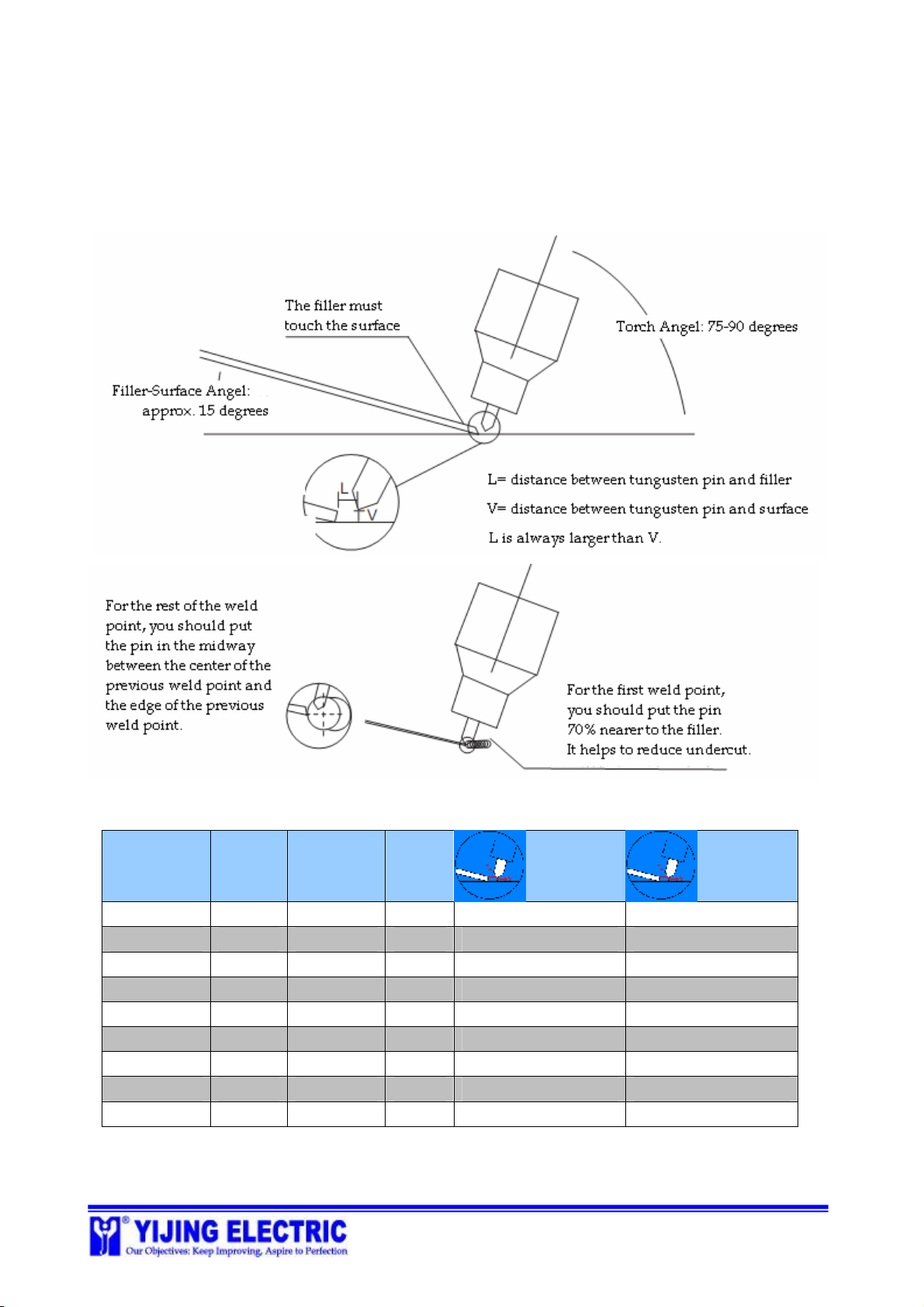

Filler

We generallyrecommendthatyouusefillerofthesametypeastheworkpiecethatisweldedon.

For iron,werecommendfillerwithlowWc%.

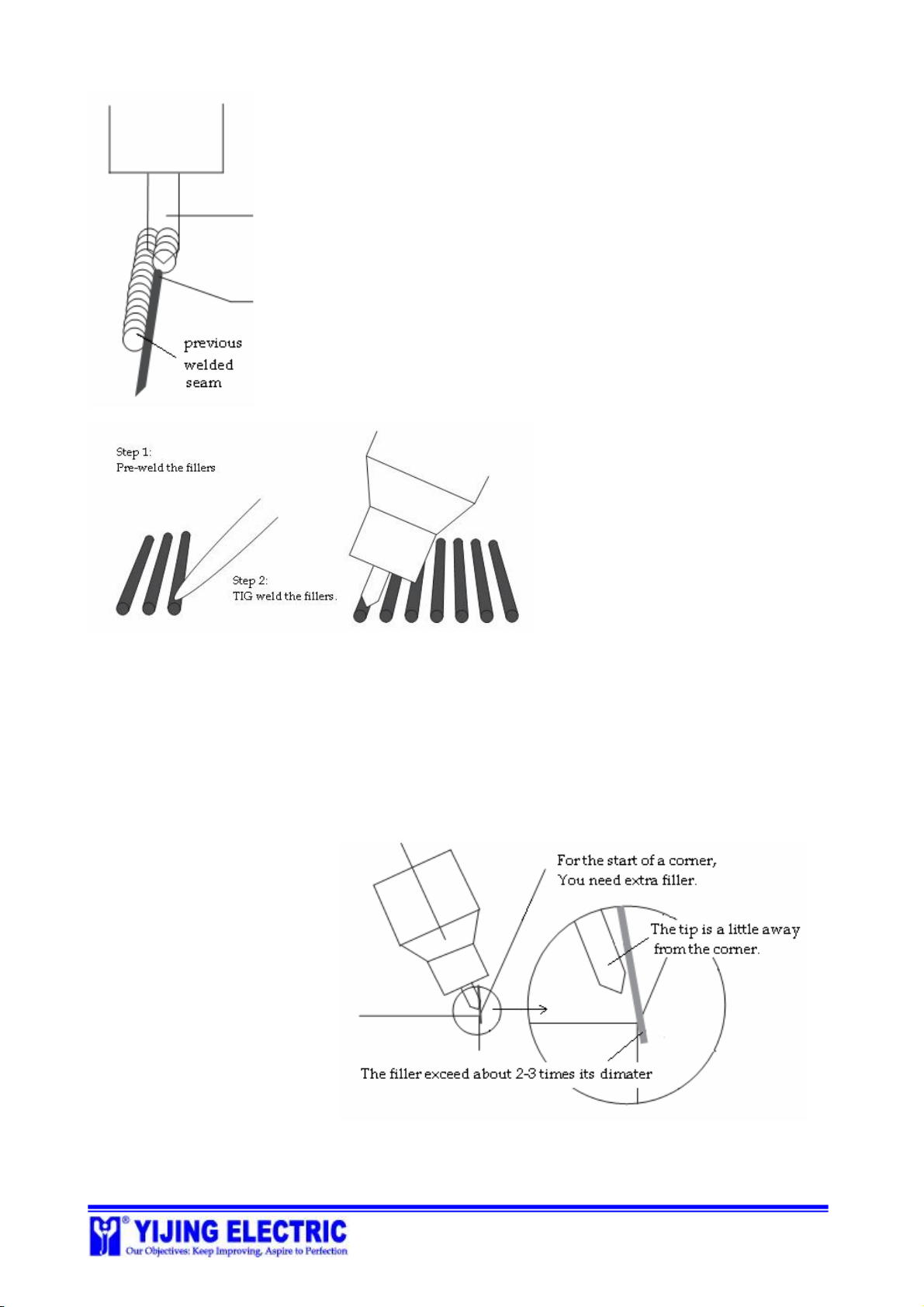

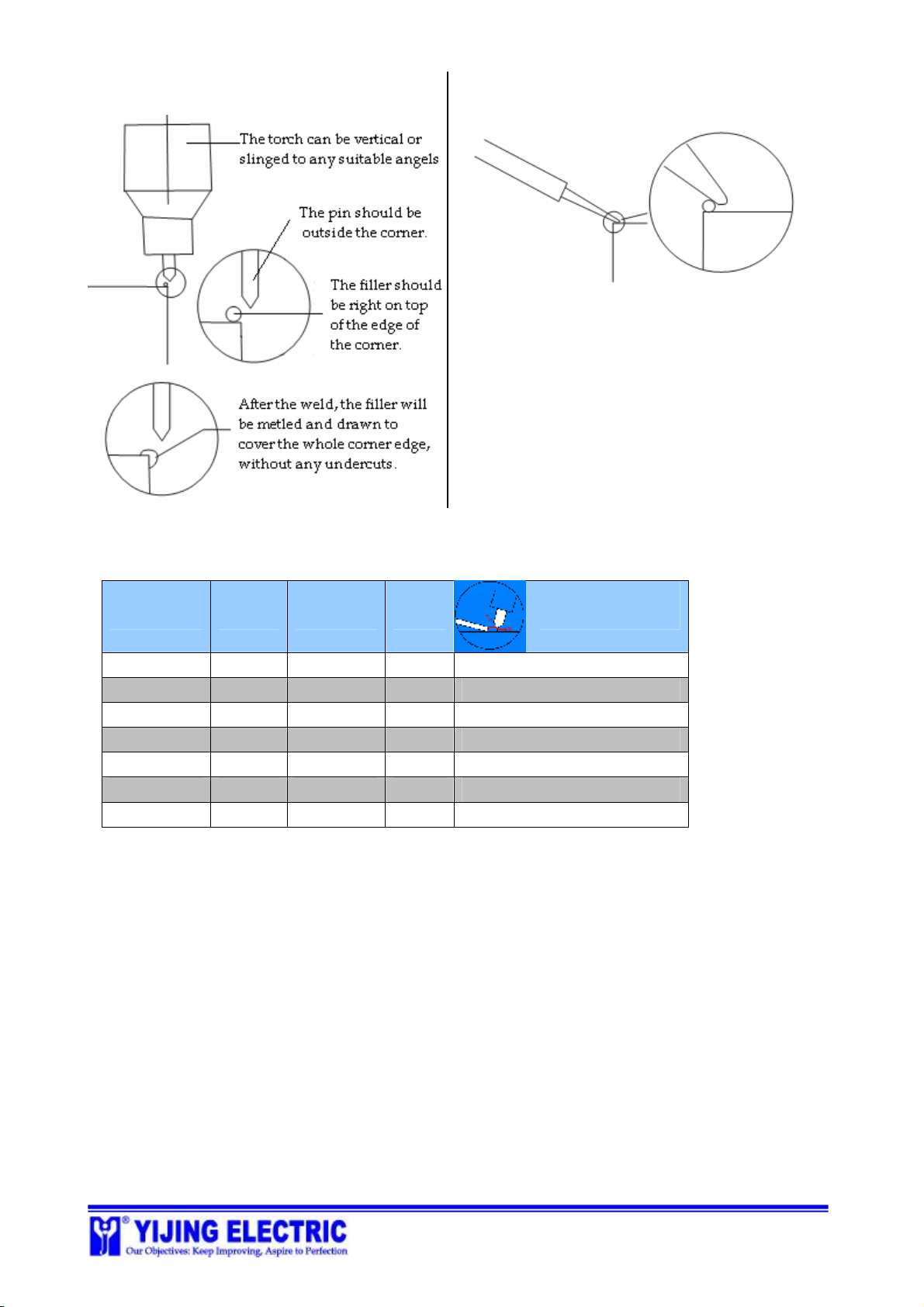

Set FillerMode

Thisfunctionisaveryusefulaid,whenyouneedweldonverydelicate,complicatedpositions.

Youcanpre-weldthefillerwithsetfillermode,andthenyouusetheTIGmodetore-weldthe

fillerthoroughly ontotheposition.

Thisfunctioncanfree yourhandfromthetraditionaltiresomewayoffeedingthefillers. Youcan

stabletheTIGwelding torchby bothyourhands andgetmuchbetterweldingquality.

This functioncanalsobeusedtopreventpotentialdamagetosurroundingareas.

To useSet-FillerMode,youmustmakesure:

1)Thegroundcableis firmlyfastenedonthefrontpanel;

2)Thegroundplateis ingood contactwiththeworkpiece;

3)Theareatobeweldediscleanandfree ofstain,grease, etc..

Duringsettingfillers, youneedtopressdownhardonthefiller.Forfillerdia.of0.3mm,we

suggestpulsecurrencyvalue30.Forfillerdia. of1.0mm,wesuggestpulsecurrencyvalue99.