Contents ...................................................................................................................02

1- How To Use This Manual......................................................................................... 04

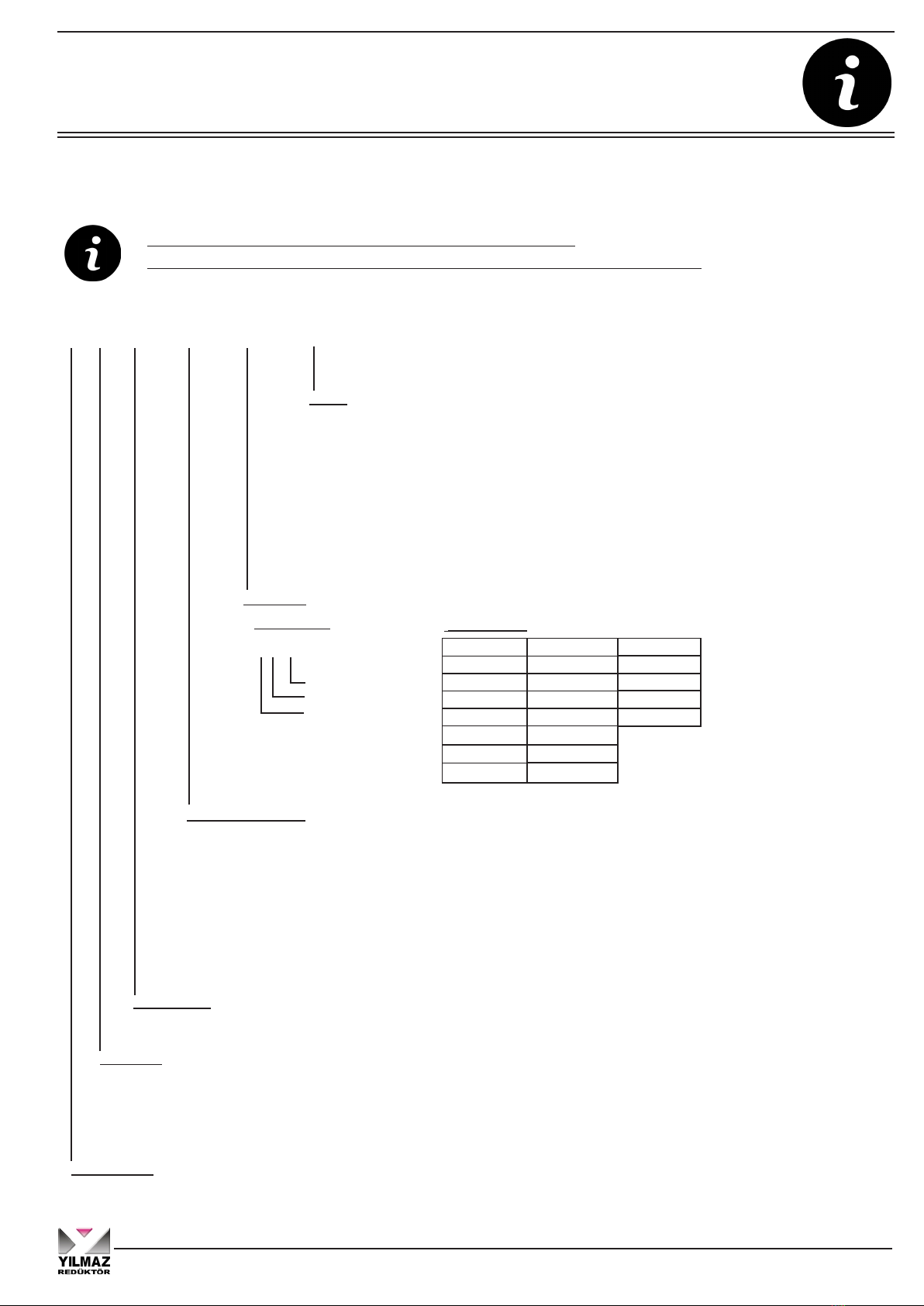

2- Type Designation ..................................................................................................... 05

2.1 Detailed unit designation............................................................................... 05

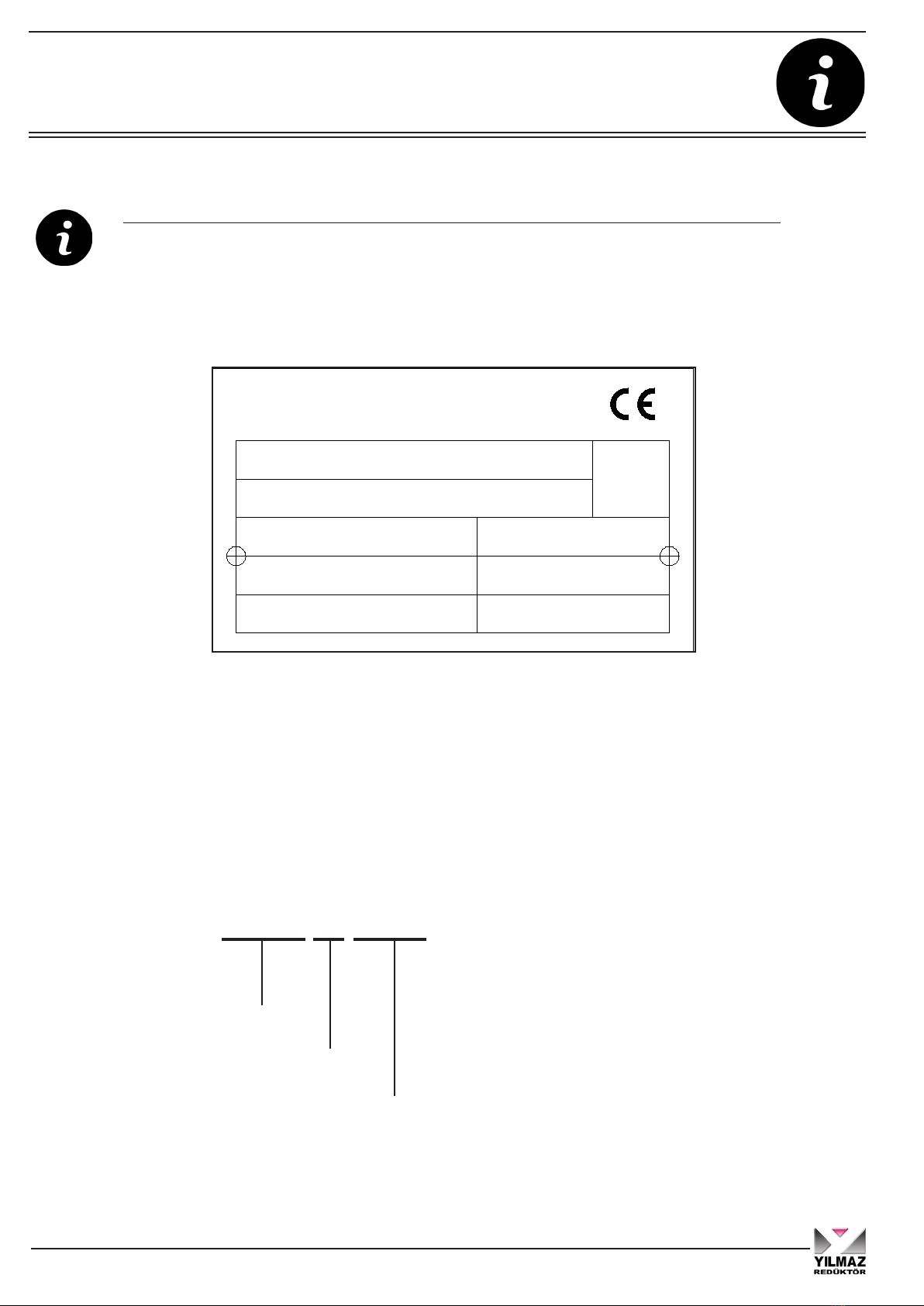

2.2 Nameplate unit designation........................................................................... 06

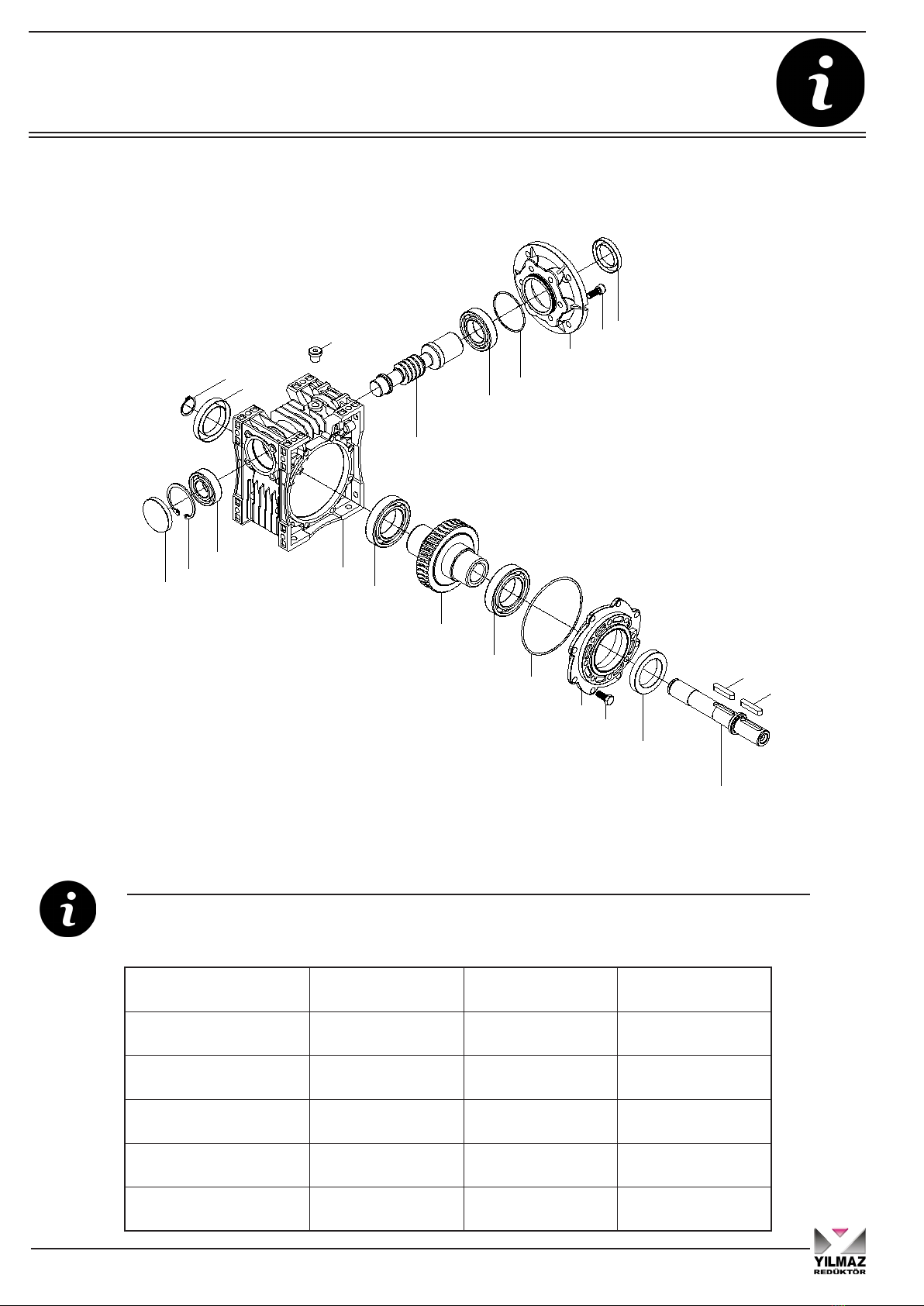

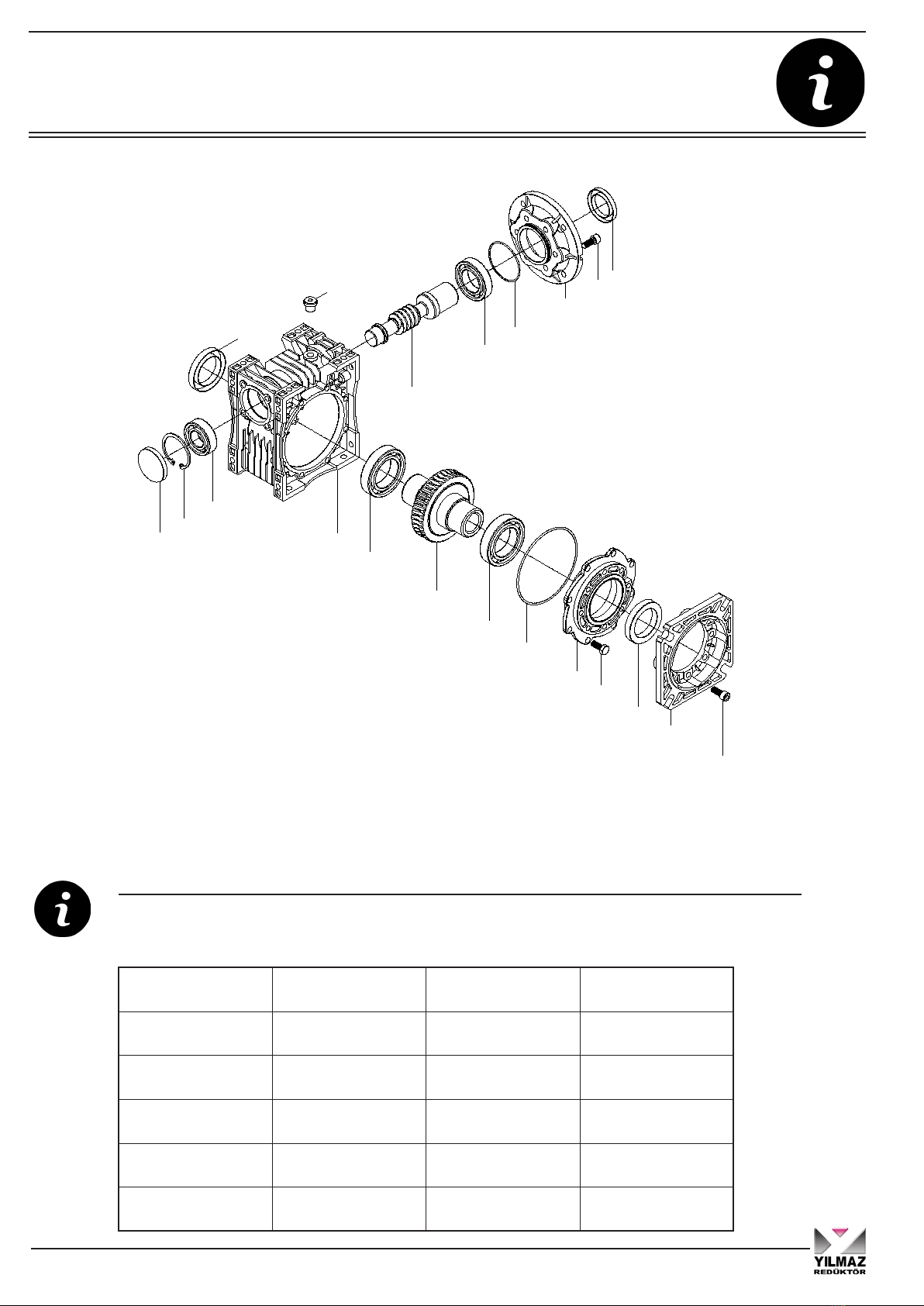

3- Part List of Standard Type Gear Units ................................................................... 07

3.01 E....00 Types ............................................................................................... 07

3.02 E....01 Types ............................................................................................... 08

3.03 E....02 Types ............................................................................................... 09

3.04 E....03 Types ............................................................................................... 10

3.05 E....04 Types ............................................................................................... 11

3.06 E....05 Types ............................................................................................... 12

3.07 E....08 Types ............................................................................................... 13

3.08 ET...00 Types .............................................................................................. 14

3.09 ET...01 Types .............................................................................................. 15

3.10 ET...02 Types .............................................................................................. 16

3.11 ET...03 Types............................................................................................... 17

3.12 ET...04 Types .............................................................................................. 18

3.13 ET...05 Types .............................................................................................. 19

3.14 ET...08 Types .............................................................................................. 20

4- Safety.......................................................................................................................21

4.1 Intented to use .............................................................................................. 21

4.2 Improper Use ................................................................................................ 21

4.3 Safety Instructions......................................................................................... 22

4.3.1 General Safety Instructions.................................................................. 22

4.3.1.1 Working on gear reducer............................................................ 22

4.3.1.2 Operation ................................................................................... 22

4.3.1.3 Maintenance............................................................................... 22

4.3.1.4 Lubricant .................................................................................... 22

4.3.1.5 Ambient Conditions.................................................................... 22

4.4 Tightining Torques......................................................................................... 23

4.5 Case of Fire .................................................................................................. 23

4.5.1 Suitable extinguishing agents, protective equipment............................ 23

4.5.2 Unsuitable extinguishing agents ........................................................... 23

5- Thinks to Check Before the Gear Unit or Geared Motor is Installed ................. 24

5.1 Transportation............................................................................................... 24

5.2 Storage ......................................................................................................... 25

6- Installing The Gear Unit .......................................................................................... 25

6.1 Before you start............................................................................................. 25

6.2 Check the shaft dimensions to fit.................................................................. 26

6.3 Check the ambient temperature.................................................................... 26

6.4 Check the voltage supply.............................................................................. 26

6.5 Check the mounting position......................................................................... 29

6.6 Use the breather plug.................................................................................... 29

6.7 Check the oil level......................................................................................... 29

6.8 Check shaft ends and mounting faces.......................................................... 29

Contents

2

Operating Instructions

E Series