YMGI •Your Modern Green Idea

6

Note From YMGI –Must Read

Dear Customers, Purchasers, Installers, and Contractors

Thank you for choosing a YMGI product.

All YMGI's products are fully tested and have passed rigorous safety, performance and manufacturing standards

before being packed and shipped. YMGI only uses suppliers that meet our strict standards for high quality and

performance for all parts. YMGI also recognizes a quality installation is equally important therefore your system

must be installed by a licensed HVAC professional. A quality installation ensures your unit will operate at its highest

efficiency and peak performance for many years of worry free comfort; while a poor installation can result in unit

failure and cause the unit to operate inefficiently, either immediately or over time, resulting in costly repairs.

Because a quality installation is so critical, YMGI provides detailed information in our manuals which will aid the

installing technician and the owner of the unit(s).

At YMGI our goal is to ensure that your YMGI units are installed properly and correctly from the beginning.

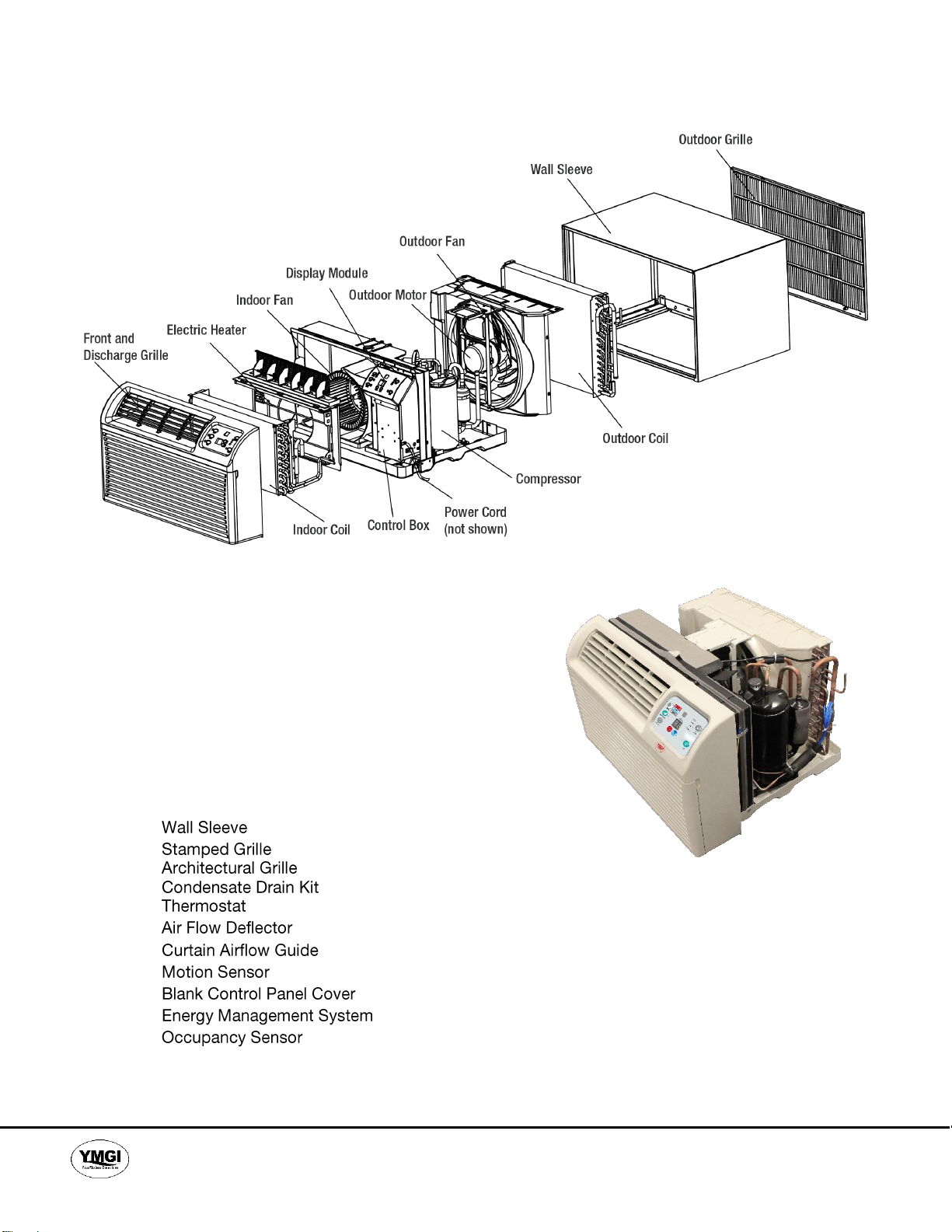

The YMGI equipment you purchased is either a split-type or a self-contained cooling/heating system. These types of

systems require a certified and licensed HVAC professional technician for proper installation. Only a certified and

licensed HVAC professional technician will have the knowledge, experience, and attention for all required details to

perform a complete and successful installation. This equipment is different from a window or portable type air

conditioners you can purchase from local retail stores such as Home Depot, Lowe's, Sears, etc. which the

manufacturer may not require certified and licensed personnel to install.

Reading and following YMGI Group recommendations and requirements contained in the following pages and

other documents, is the first step to help ensure a smooth installation and proper operation of your unit for many

years.

YMGI doesn't recommend nor allow any do-it-yourself (DIY) installation (partially or fully). Due to the complexity of

the installation of this product most DIY installations usually have problems, either immediate or near future. These

problems can cost more to fix than any upfront savings. YMGI warranty does NOT cover any DIY units.

If you have any questions about your unit or if the unit has a problem, you should first check the manual. If you

can’t find a solution, then contact your local installer or service technician to schedule a service appointment. The

technician can physically inspect the unit. If at the time of inspection, the installer or service technician has any

questions about the unit, they can contact YMGI technical support division directly at:

Toll Free Number: (866)833-3138 or Email: techsp@ymgigroup.com

IMPORTANT: YMGI Group is the MEDIA AUTHORITY:

YMGI Group, located in O'Fallon, MO, is the author of all media produced for its products and is the only party able

to give any additional explanation for any data, definitions and or descriptions found within any of its media, including

but not limited to YMGI product brochures, manuals, pamphlets, catalogs, and videos. YMGI's distributors, installers,

dealers, agents, customers or any other third parties will not supersede YMGI in anyway concerning YMGI-published

materials and their meaning. Any concerns or questions arising from YMGI distributors, installers, dealers, agents,

customers or any other third parties, should be presented directly to YMGI. YMGI will respond to any concerns or

questions, if necessary, about any of its media in writing.