Contents

ContentsGeneral........................................................................... 5

Safety Considerations............................................. 5

Inspection................................................................ 6

Reference................................................................. 6

Renewal Parts.......................................................... 6

Approvals................................................................. 6

Nomenclature.......................................................... 8

Installation..................................................................... 9

Installation Safety Information............................. 9

Preceding Installation............................................. 9

Limitations....................................................... 12

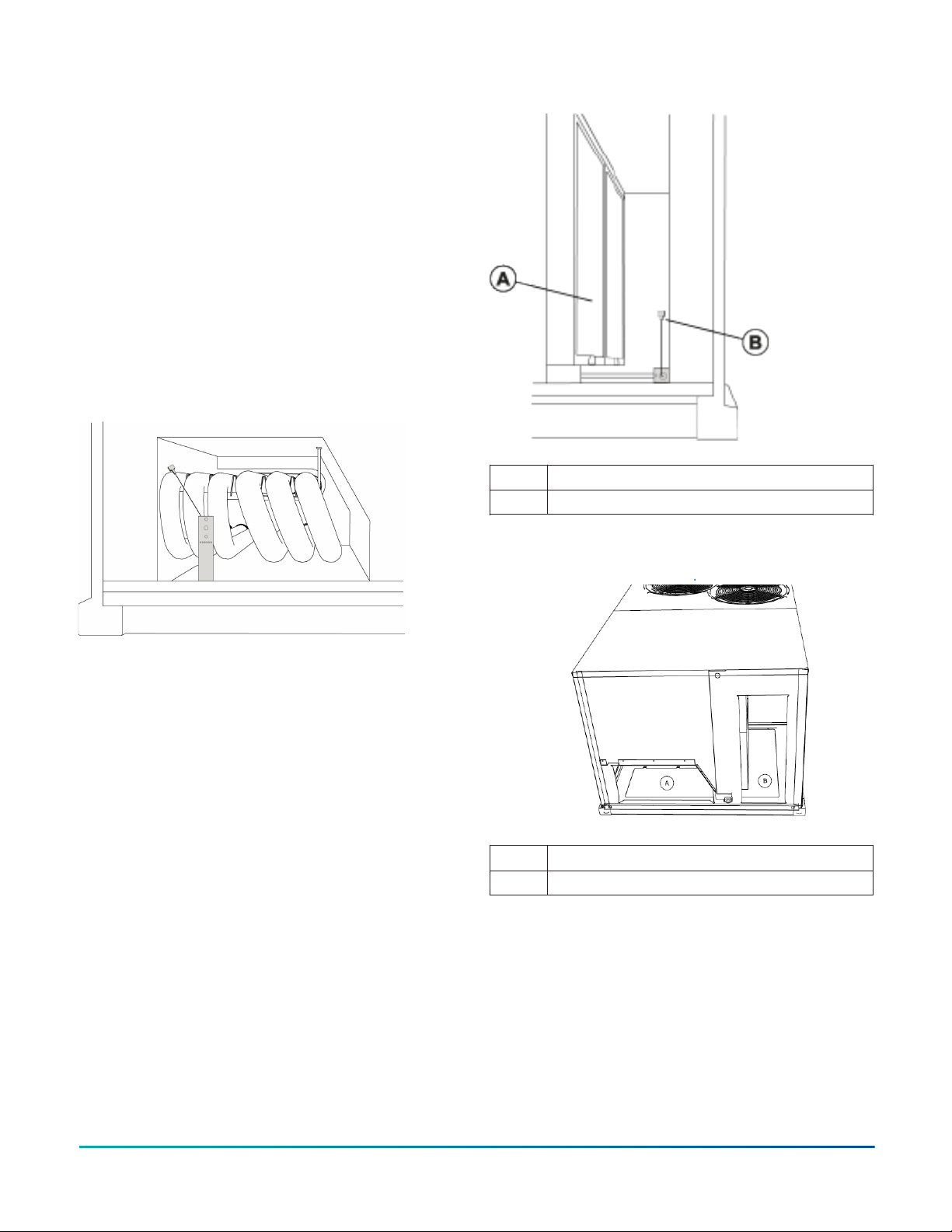

Location.................................................................. 12

Clearances........................................................ 12

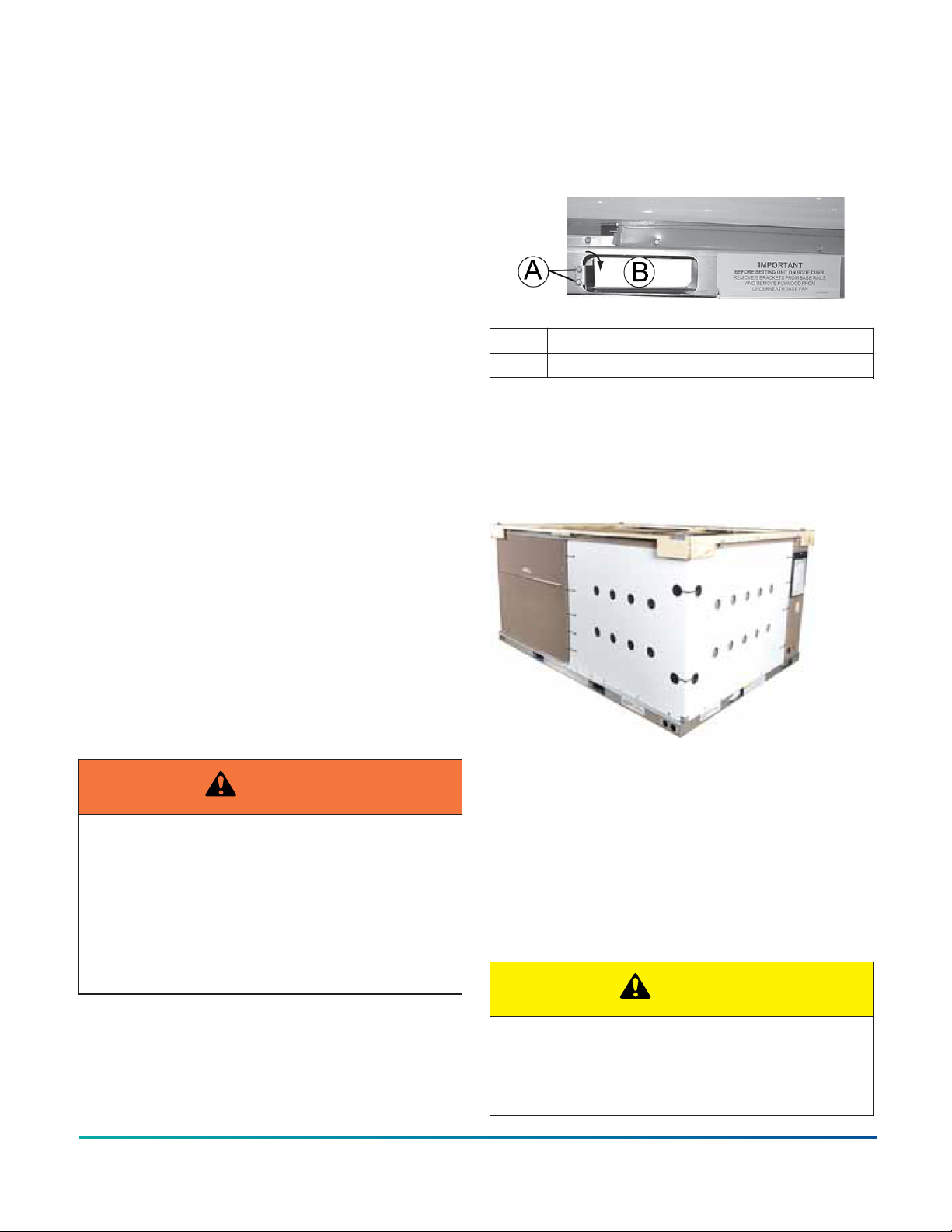

Rigging and Handling........................................... 13

ZXA7, 08-14 Unit Weights..................................... 14

Ductwork................................................................ 20

Duct Covers...................................................... 20

Condensate Drain................................................. 21

Compressors.......................................................... 22

Filters...................................................................... 22

Power And Control Wiring................................... 22

Thermostat Wiring.......................................... 23

Typical Field Power and Control Wiring................... 24

Typical Power Wiring............................................ 24

Electrical Data........................................................ 26

ZXA7, 08 to 14 Standard Static Indoor

Blower - With Powered Convenience

Outlet................................................................. 26

ZXA7, 08 to 14 High Static Indoor Blower

- With Powered Convenience Outlet.............. 29

ZXA7, 08 to 14 High Static Indoor Blower

- Without Powered Convenience Outlet........ 32

ZXA7, ZX08 to 14 Medium Static Indoor

Blower - Without Powered Convenience

Outlet................................................................. 35

ZXA7, ZX08 to 14 Medium Static Indoor

Blower - With Powered Convenience

Outlet................................................................. 38

ZXA7, 08 to 14 Standard Static Indoor

Blower - Without Powered Convenience

Outlet................................................................. 41

Physical data ZXA7, 08 to 14................................ 44

Optional Gas Heat................................................. 54

Gas Piping........................................................ 54

Gas Connection............................................... 54

Combustion Air and Flue Exhaust................. 55

Options/Accessories............................................. 56

Economizer...................................................... 56

Power Exhaust................................................. 56

Rain Hood......................................................... 56

Blower Phasing...................................................... 56

Blower Rotation............................................... 57

Belt Tension..................................................... 58

Altitude and Temperature Correction for

CFM, Static Pressure and Power..................... 58

Airflow Performance............................................. 61

ZXA7, 08-14 Side Duct Application (Belt

Drive)................................................................. 62

ZXA7, 08-14 Bottom Duct Application

(Belt Drive)........................................................ 65

RPM selection.................................................. 68

Supply Air Drive Adjustment.......................... 68

Everyday Thermostat Control (ETC).............. 71

Smart Equipment™ unit control board......... 75

Operation..................................................................... 80

Cooling sequence of operation........................... 80

Electric Heating Sequence of Operations.......... 83

Electric Heat Operating Errors....................... 83

Gas Heating Sequence of Operations................ 83

Gas Heat Operation Errors............................. 84

Indoor Air Quality AQ........................................... 86

Gas Heating Operation......................................... 86

Gas Heat Ignition Control Board Function............... 87

Ignition Control Board on Standby..................... 87

Call for heat........................................................... 87

Pressure switch proving....................................... 87

Pre-purge............................................................... 87

Ignition trial period............................................... 87

Flame stabilization period.................................... 87

Main Burner operation......................................... 87

Post Purge.............................................................. 88

Lockout................................................................... 88

High temperature limit switch............................ 88

Roll-out switch....................................................... 88

Power interruptions.............................................. 88

Flame present with Gas off.................................. 88

Welded gas valve relay response........................ 88

Cooling start-up.......................................................... 89

Prestart Check List................................................ 89

Operating instructions......................................... 89

Johnson Controls Ducted Systems

INSTALLATION MANUAL ZX SERIES 6-12.5Ton 60 Hertz R-410A 3