035-14511-001 Rev. A (0602)

10 Unitary Products Group

ENERGIZE CRANKCASE HEATER

This unit is equipped with a crankcase heater for the com-

pressor.

A warning label with an adhesive back is supplied in the unit

installation instruction packet. This label should be attached

to the field supplied disconnect switch where it will be easily

seen.

IMPORTANT - An attempt to start the compressor without

at least 8 hours of crankcase heat will damage the compres-

sor.

In order to energize the crankcase heater, set indoor two

stage cooling thermostat to "OFF" position. Close the line

power disconnect to the unit.

SYSTEM OPERATION

FIRST STAGE COOLING

With a call for first stage cooling, the compressor operates

one cylinder. The run winding (R) is connected through con-

tactor A to the capacitor and the start winding (S) is con-

nected to line voltage. The system operates at low discharge

pressure and high suction pressure.

SECOND STAGE OF COOLING

With a call for second stage cooling, the TS control will shut

the compressor off for two seconds then energize relays R1

and R2 on the TS control board. This will de-energize (open)

contactor A and energize (close) contactor B, connecting the

compressor run winding (R) to line voltage and the start wind-

ing (S) to the capacitor. The compressor runs in the reverse

direction with two cylinders compared to the first stage. The

system will operate with two cylinders until both first and sec-

ond stage are satisfied. The Y2OUT signal from the TS con-

trol causes the indoor blower to function at high speed.

If the room thermostat calls for second stage cooling (Y2) on

two consecutive cooling cycles, the next call for cooling for

either first or second stage will energize the unit in second

stage mode. The above mode will be reset to permit start up

on the first stage with only a Y1 call when the second stage

operation cycle runs less than 15 minutes or when 24V to the

TS control board is disconnected.

NOTE: The TS control must have a Y1 and a Y2 call to run

in second stage. A Y2 call without a Y1 call will not cause the

system to operate.

DEHUMIDIFICATION

The product is designed to run longer on first stage than a

regular single speed compressor system. This additional run

time provides for better dehumidification and consistent room

temperatures. However, there may be installation environ-

ments in which the humidity levels are unacceptable. In this

case the addition of a humidity control will resolve these

issues.

A humidistat installed with a variable speed air handler or fur-

nace reduces the airflow of the blower by 15% of the pro-

grammed speed during the dehumidification mode. This

lower airflow reduces the evaporator temperature increasing

the latent capacity. The humidistat for these variable speed

systems opens the humidistat contacts on humidity rise.

They are wired to the control system per Figure 7.

A dehumidistat installed with a single speed or 2-speed air

handler or furnace will force the system into second stage

mode to increase the latent capacity. It is critical that the low

speed blower operation is set as close to the recommended

airflow as possible to limit the number of times the unit will

run second stage for dehumidification purposes. The dehumi-

distats for these systems close the dehumidistat contacts on

humidity rise. They are wired to the control system per Fig-

ures 8 through 10.

ANTI-SHORT CYCLE TIMER

The control has a five minute time delay to prevent the sys-

tem from short cycling after a thermostat off cycle or power

interrupt. This five minute delay is initiated following the com-

pletion of a first stage cooling call (Y1) or the 24v power up of

the control. During this mode the control will not respond to

any thermostat inputs and the LED will flash a code 1 at the

control board.

For servicing or during installation of the condensing unit, the

time delay may be bypassed by momentarily jumping the two

test pins when there is a call for cooling (Y1 or Y2).

PRESSURE SWITCH OPERATION

The condensing unit is provided with high and low pressure

switches installed and wired into the control to provide addi-

tional protection for the system if any abnormal operating

conditions occur. The high pressure switch is threaded on a

Schrader fitting located in the liquid line of the outdoor unit

and a low pressure switch is brazed in the suction line of the

outdoor unit. These two controls are wired in series to the unit

control.

If the pressure switches detect a fault condition, they will

open (high pressure opens with pressures greater than 400

psi and low pressure opens with pressures less than 25 psi)

and the control will immediately shut down the unit. The con-

trol will go into a five-minute anti-short cycle mode inhibiting

any thermostat inputs. Following the anti-short cycle mode,

the control will permit the unit to start normally with the next

call for cooling as long as the pressure switches have reset

(high pressure resets at 300 ± 15 psi, low pressure resets at

65 ± 7 psi).

If the control detects a second pressure switch fault within

one hour of compressor run time, the unit will again shut

down and the unit control will lock out the unit until the fault

condition is reset. During this period, a code “2” will be

flashed at the control and provide a 24v signal on the X/L line.

HeartBeat – LED flash rate of 500 ms ON and 500 ms OFF

Flash/Error Code – LED flash rate of 350 ms ON and 350 ms

OFF for the number of codes and with a pause of 1.5 sec-

onds between flash codes.

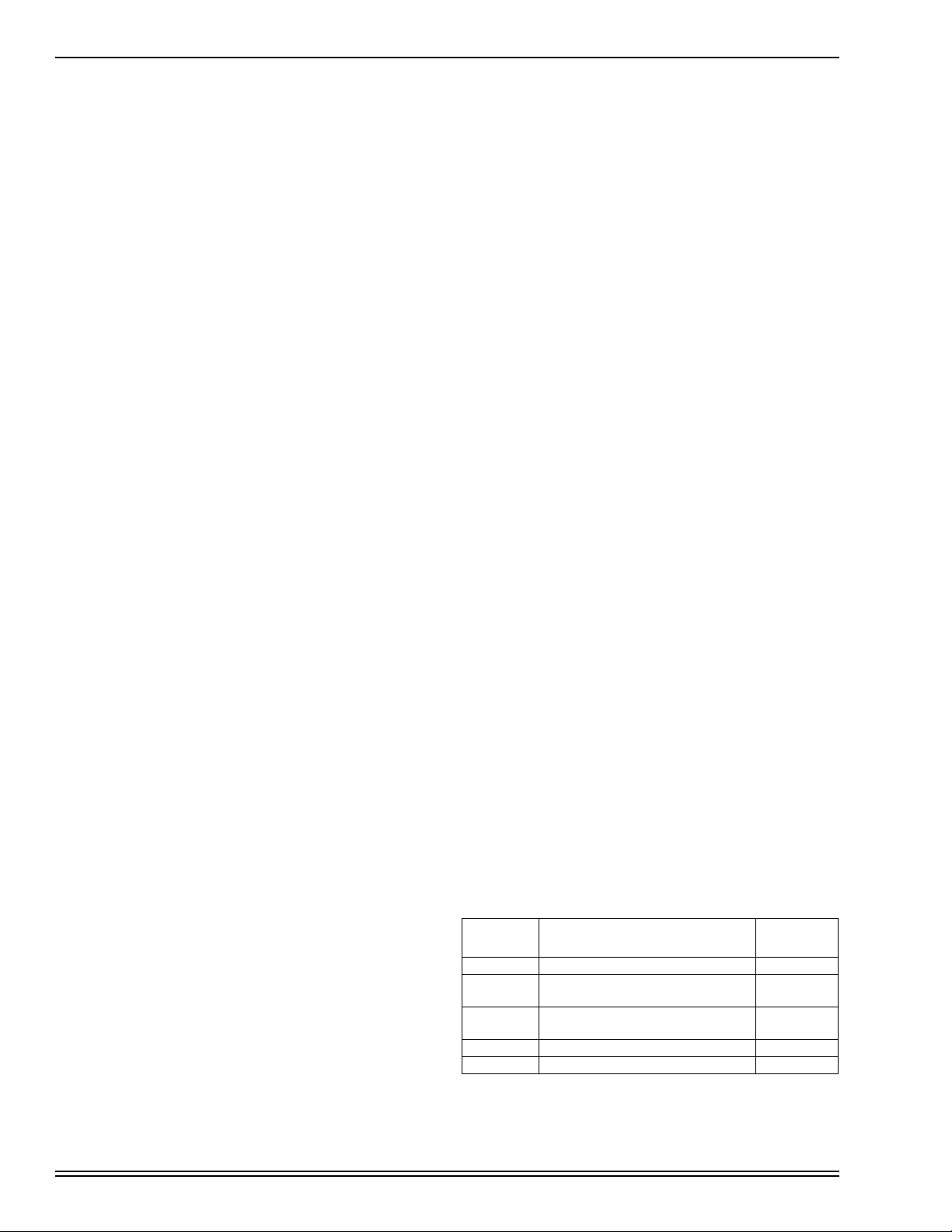

Table 3: FAULT CODES

TS Control

LED Description 24V @

X/L line

HeartBeat Normal Operation None

1 Flash Compressor waiting to complete

Anti-short cycle period None

2 Flash Compressor lockout out on safety

chain trip Yes

On Steady Control Failure Yes

Off No power or Control Failure