530 25-N2

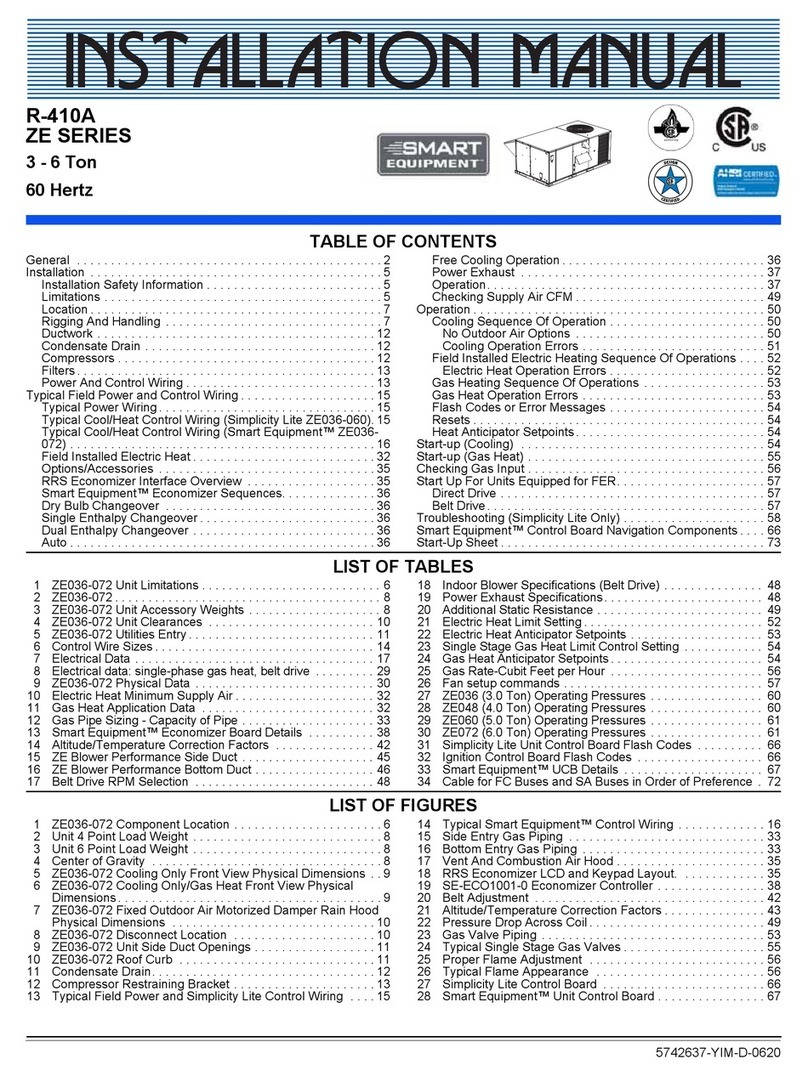

TABLE OF CONTENTS

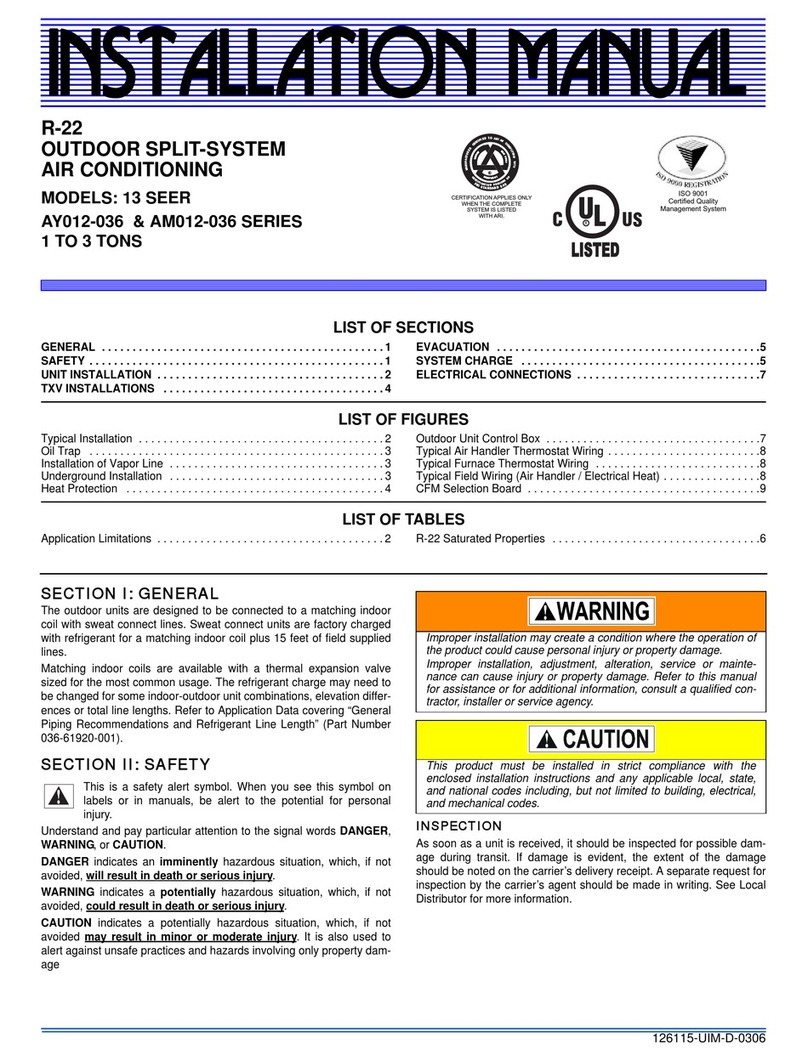

GI:NERAL 1

INSPECTION I

REF1REN(’I 1

NOMIN(’LAT(IRL INSTALLATION 2

L[ MIT ATIOXS 3

RI(;GINC; 3

kloliNTING .3

(’L1;ARAN(’tS.3

coNDLNsATI.DRAlk”CONN1(TION 4

POWLR AND (’ONTKOLW[RING

Powc[ Wll Ing 4

(’ontfol Wiring .,, .,, 6

r)~l(”_f COP4SL(’ rloNS 11

f-lLT1KS 11

1(’ONO\llZf RRAIN’H6fi)~’bPTiOiV’:: ::: 12

FIXEDOUTDOOR AIRRAINHOOD : 12

IXliAUST AIR RAIN HOODOPTION ., ]~

STATICPRESSUREREGULATOR AND CONT”ROL: 12

OPERATION

DISV VARIABLEAIR VOLUME ., 12

GENERAL . . . . 12

COOLING ., .’: : : : : 13

Economizer System, ., . . 14

Damper LinkageAdjustment, ., ., 14

Hwrtmg Systcm 14

Au Volume Control System 14

Check]ngLlnk~geon Alr Volume D~m”pers 15

Checkout Procedure 15

Exhaust Alr System 15

SUPPLYAlRBLOWERADJUSTM1+T : : 16

MASTLRPRINTLDCIRCLIITBOARDAND

PLUC;-INRELAY ASSEMBLY 18

SE.f<VICE.ANALYZt R18

FIXEDOUTDOORAIR ADJUSTMENT :19

t:XllAUST AIR PI RFORMAN(’L 19

START-UP

PRE START-UPCHECKS -)’-!

. .

pre-stsrt Steps and procedures 7-J

--

INITIALSTART-UPCHECKS 23

SAFETYAND SERVICE FEATUkES .23

MAINTENANCE

FILTERS ., . . . ... , . . . . . . . . ... . 24

COILS ..................... ., 24

DRAINPAN .24

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . 24

BELTS . . . . . . 24

REFRIGERANT CtlARGE R-22 24

FIGURE

I

>

<

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

][]

TABLE

1

7

3

4

5

6

7

8

9

10

11

LIST OF ILLUSTRATIONS

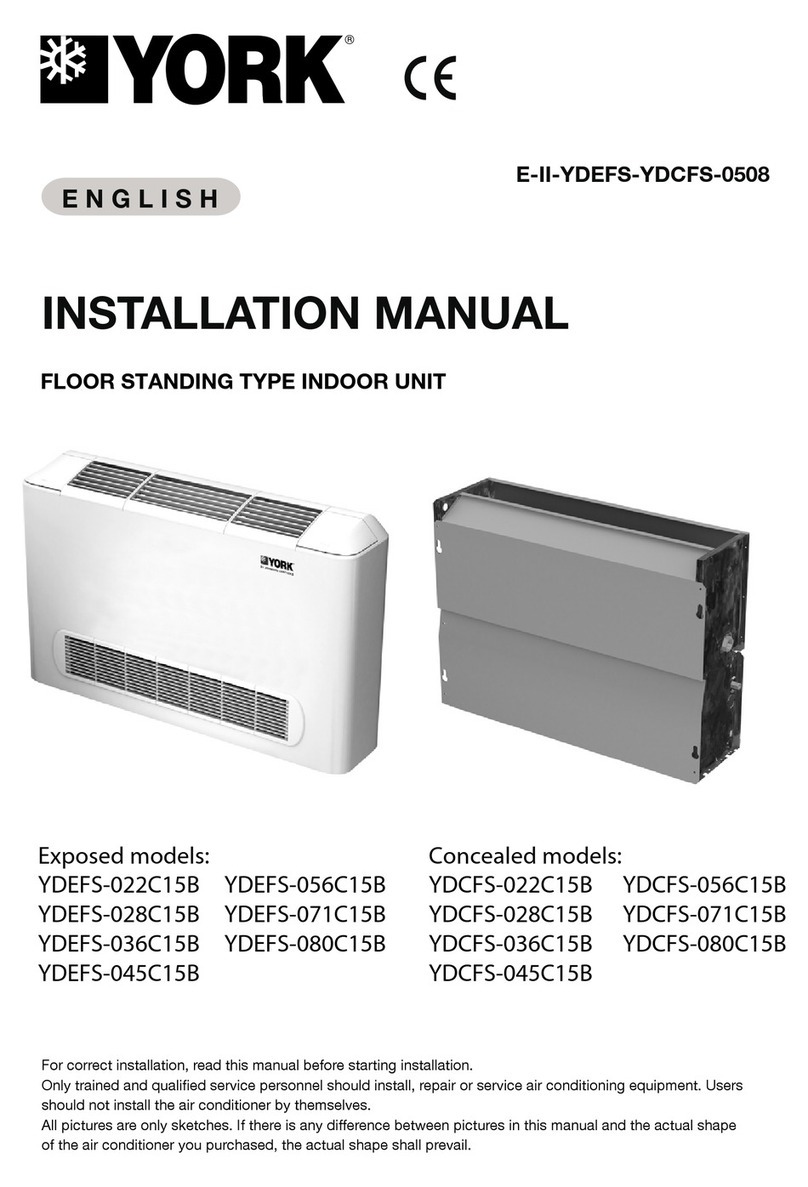

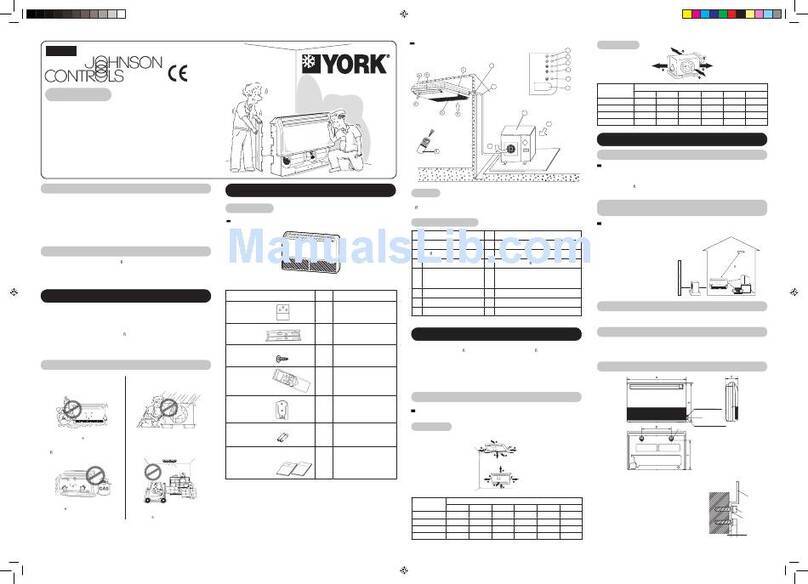

Un It Le;$ P;incls ~

r~pIcdlUn] tRlgg(ng 3

(’enter (JI Gr~v]ly 3

lk~omn]cndcd Drain P]prrrg 4

Bottom Power Wrrlngl.ntran~e 5

Side PuwerWlrlnglmtrancc 5

Control Wumg Entrance (DSV300,”360) ~:6

Control WlrmgEntrance (DSV480) 6

Control Wrrmgand Static Pressure Con-

nect inns, D1SV Un]t With A]r Volume

Dampers 7

Un]t l)lnlcrr~lons . . . . 10

Duct Conncctlons . . . . 11

Sound Ahsorptlon Chamber .11

Internsl V[ewof DamperMotor EndSwltcb :1s

AdjustingDamper Motor End Switch 15

Typical Motor Mountlrrg Assembly 16

IIole Locations For Supply Alr (’FM(’beck 17

PressureDrop Acruss IIvapordtor (’oil 17

I;rxcd Outdoor Alr AdJir\tnlcnt 19

l;xhaus[ ArrPert orlmince 19

LIST OF TABLES

Appllcti[lon lli[a 4

Cunlponcnl Wcight~ 4

Llcctrlcdl Dtita .8

I-rltcr Kcqulrcrnentj 11

Ambient Thernmstat %ttlng 14

En[halpy (’ontroi (%[ Ilrlnt “B’ . . 14

Supply ArrSystem Adjustment 16

ScrvrceAnaly/cr Function Chart 18

BlowerMotor And Drlvc Da[ir 20

Rc\rsttsr]cc\-Untt Options ~nd Atxc\sorm~ 20

Supply Alr BlowerPcrlormancc 21

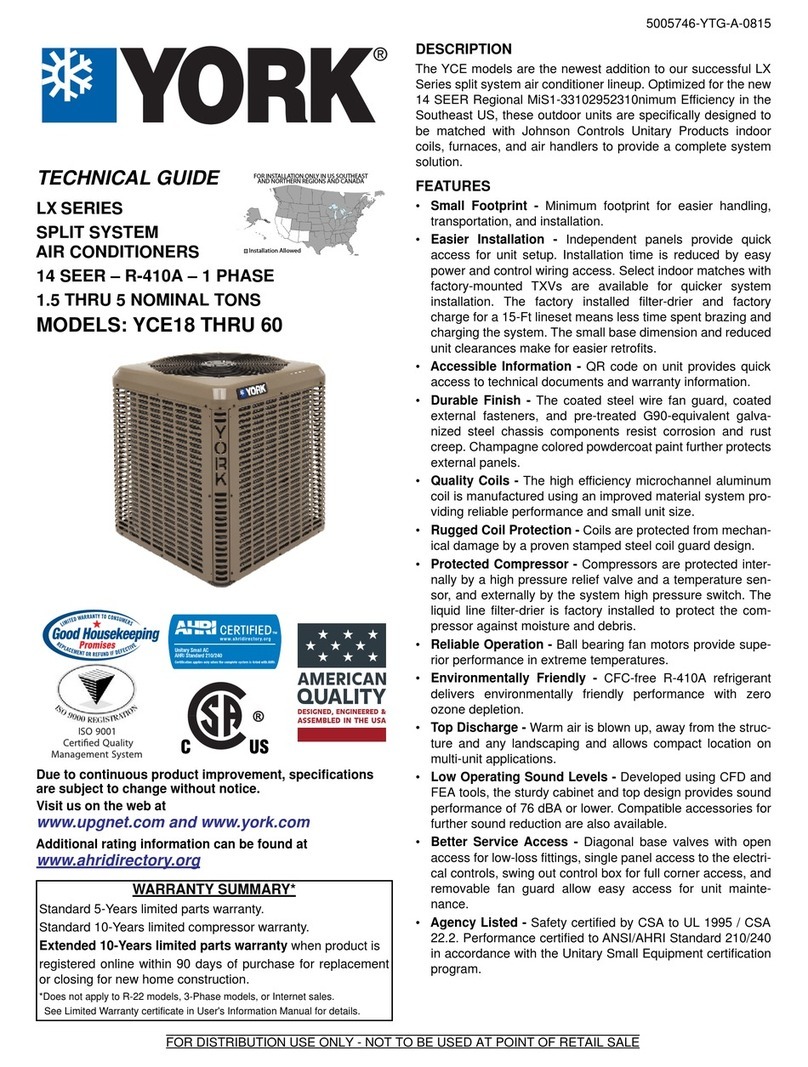

PRODUCT IDENTIFIER -

SV =VAV Sunllne

I

ink-l

J

COOLING

CAPACITY

300 =25 Tori

360 =30 Ton

480 =40 Ton

FACTORY INSTALLED HEAT

E=Electric

G=Gas (Multl-Fuel)

A=Not Applicable

I

I,=

‘aEa

NOMINAL HEATING CAPACITY

Gas Electric

400 =400 Mbh 040 =40 KW

560 =560 Mbh 060 =60 KW

800 =800 Mbh 080 =80 KW

100 =100 KW

120 =120 KW

-

-

-

2con troll EIIVIronmf,llt,i ISyslf,ms