AYK550-UH User’s Manual

Table of Contents

Table of Contents

Safety

Use of Warnings and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

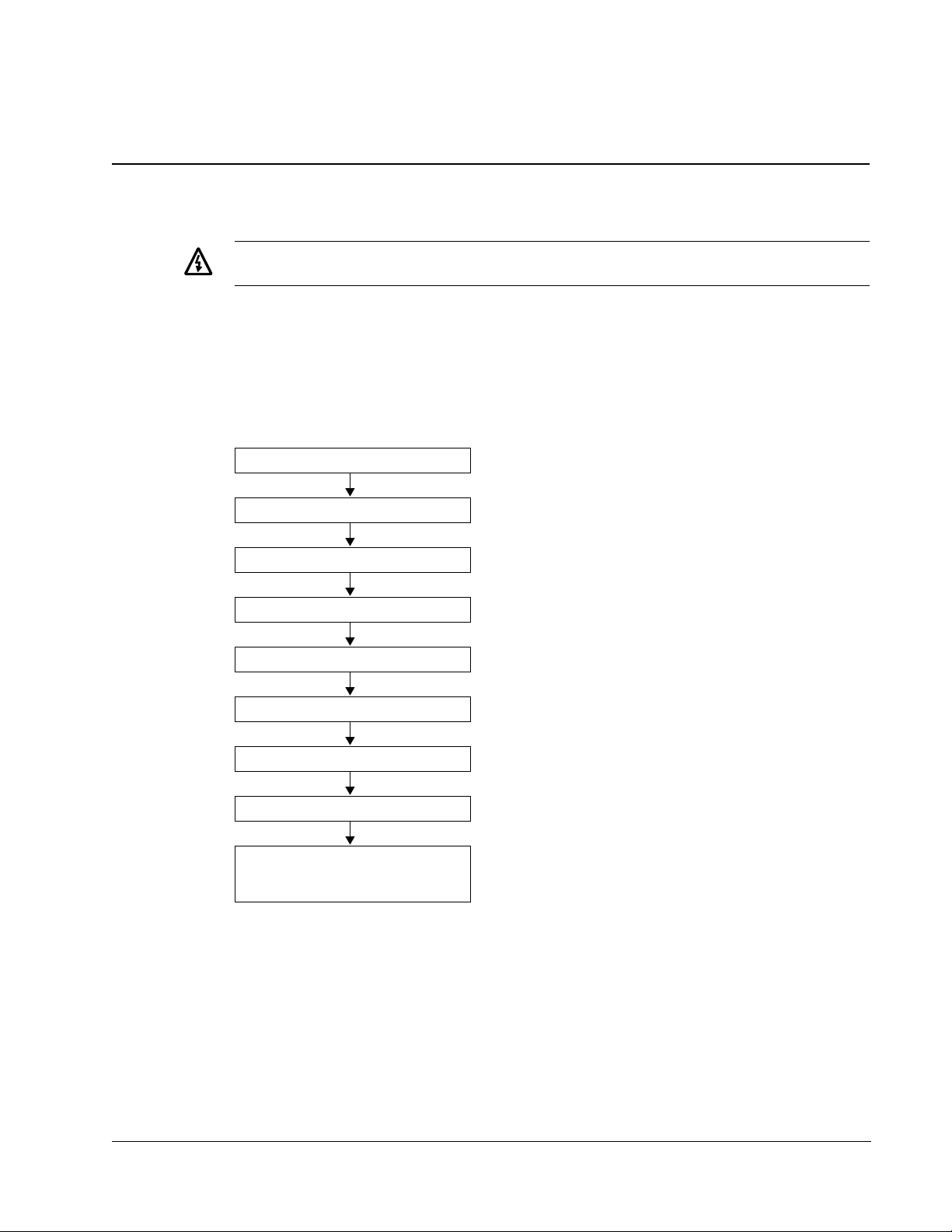

Installation

Installation Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start-Up

HVAC Control Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Application Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

YORK Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Serial Communication – EFB

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Mechanical and Electrical Installation – EFB . . . . . . . . . . . . . . . . . . . . . . . . . 142

Communication Set-up – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Activate Drive Control Functions – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Feedback from the Drive – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Diagnostics – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Modbus Protocol Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

YORK Drives Profile Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

N2 Protocol Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

FLN Protocol Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

BACnet Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Serial Communication – FBA

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Mechanical and Electrical Installation – FBA . . . . . . . . . . . . . . . . . . . . . . . . . 193

Communication Set-up – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Activate Drive Control Functions – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Feedback from the Drive – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Diagnostics – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

YORK Drives Profile Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Generic Profile Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Diagnostics

Diagnostic Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Correcting Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Correcting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215