2

CONTENT

1 Brief Introduction ----------------------------------------------------------------------------------------- 3

2 Safety --------------------------------------------------------------------------------------------------------- 3

2.1 Self-Protection --------------------------------------------------------------------------------------------- 3

2.2 Cautions ---------------------------------------------------------------------------------------------------- 4

2.3 Safety Precaution for Installation and Location ------------------------------------------------------ 4

2.4 Security Check -------------------------------------------------------------------------------------------- 5

3 Technical Description ------------------------------------------------------------------------------------- 5

3.1 Environment ----------------------------------------------------------------------------------------------- 5

3.2 Input Power ------------------------------------------------------------------------------------------------ 6

3.3 Equipment Principle -------------------------------------------------------------------------------------- 6

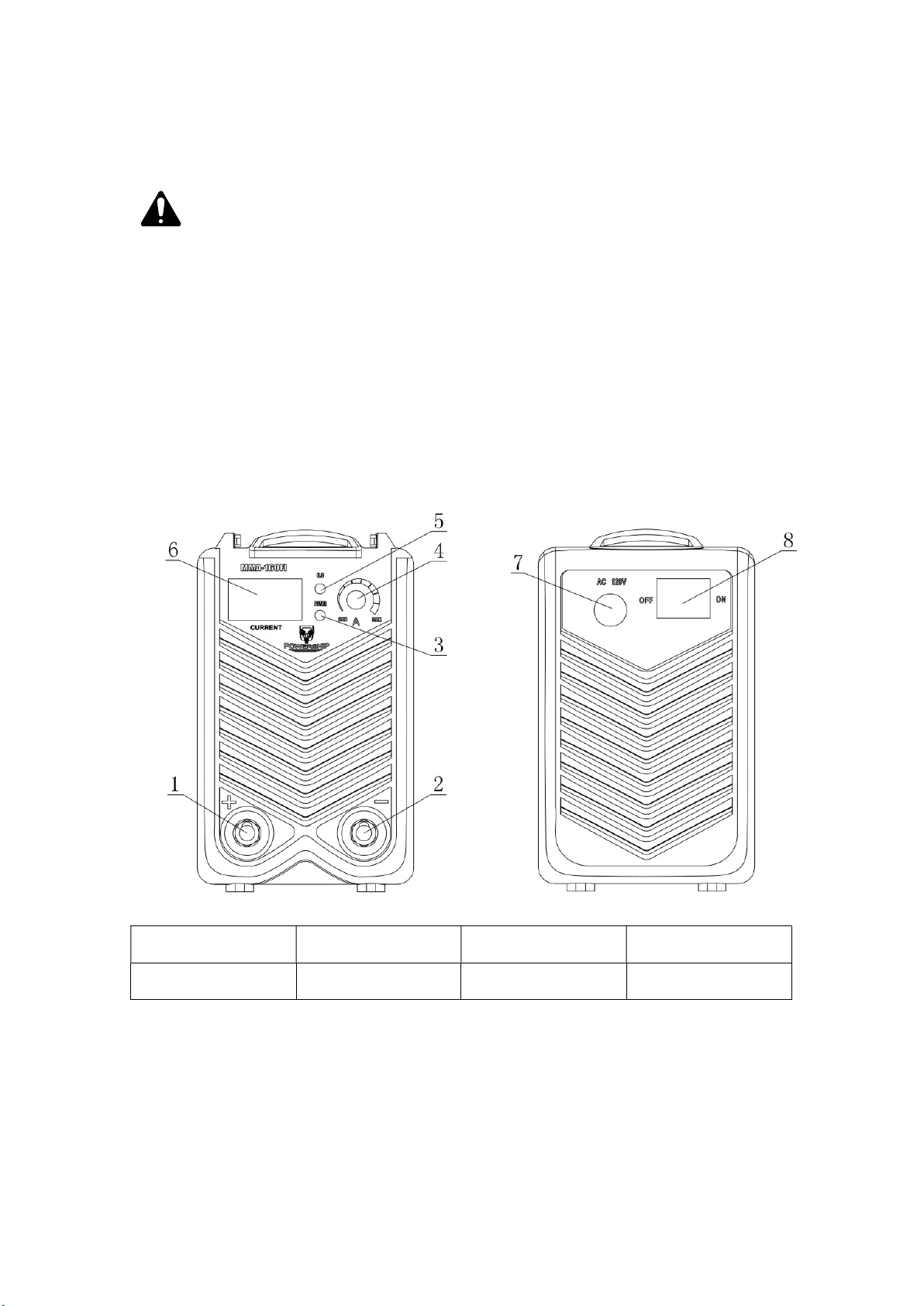

3.4 Equipment Structure -------------------------------------------------------------------------------------- 6

3.5 Guide for Marking Models ------------------------------------------------------------------------------ 7

3.6 Parameter --------------------------------------------------------------------------------------------------- 7

3.7 Standard ---------------------------------------------------------------------------------------------------- 8

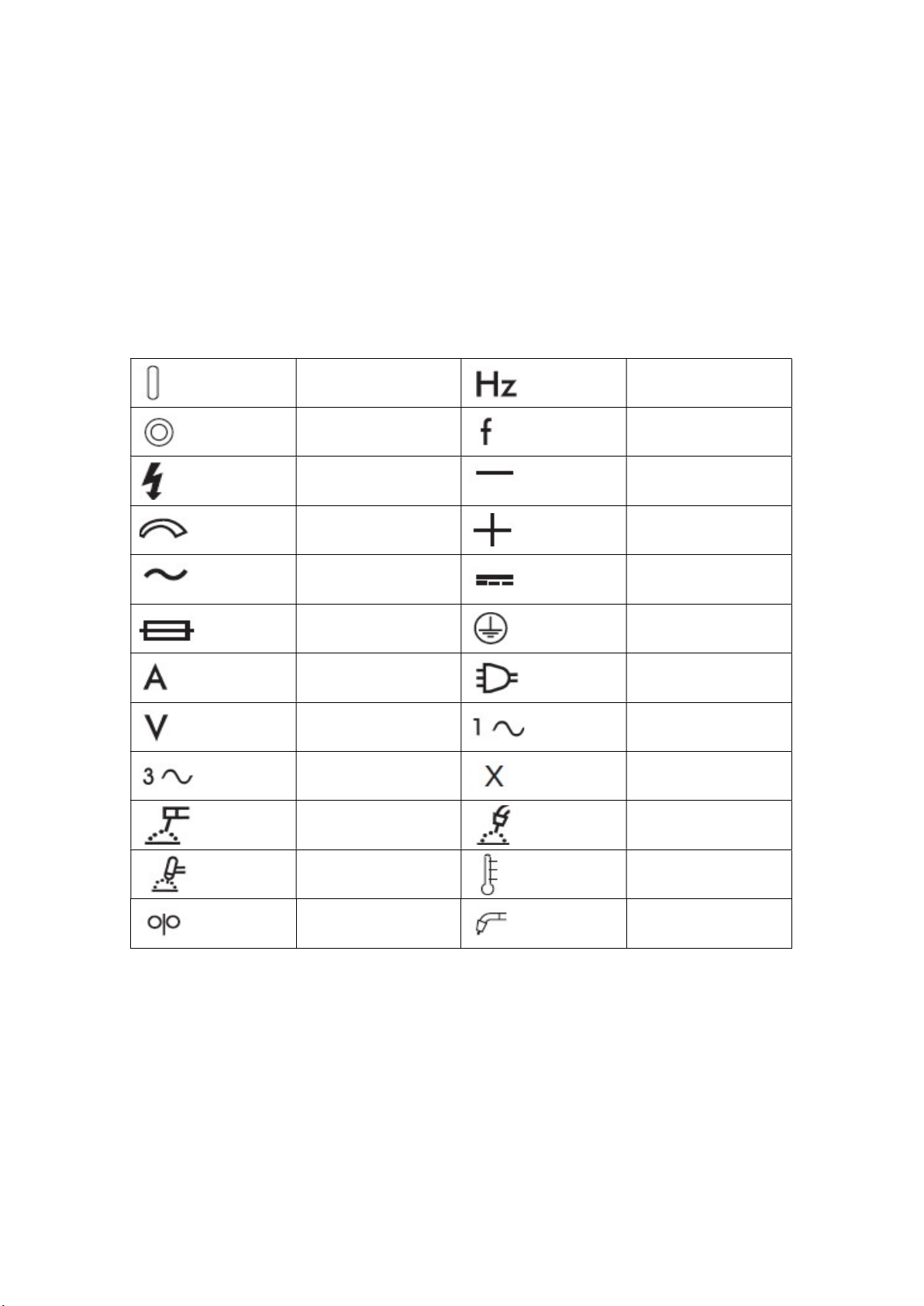

3.8 Symbol Chart ---------------------------------------------------------------------------------------------- 8

4 Installation -------------------------------------------------------------------------------------------------- 8

4.1 Connection ------------------------------------------------------------------------------------------------- 8

4.2 Power Source Connection ------------------------------------------------------------------------------ 9

4.3 Electrode Polarity ---------------------------------------------------------------------------------------- 9

4.4 Workpiece Connection ---------------------------------------------------------------------------------- 10

5 Operation Instruction ----------------------------------------------------------------------------------- 10

5.1 Procedure ------------------------------------------------------------------------------------------------- 11

5.2 Electrode Replacement --------------------------------------------------------------------------------- 11

5.3 Slag Removal -------------------------------------------------------------------------------------------- 12

5.4 Maintenance ---------------------------------------------------------------------------------------------- 12

6 Basic Trouble Shooting ---------------------------------------------------------------------------------- 13

7 Parts List --------------------------------------------------------------------------------------------------- 14

8 Interconnection Diagram ------------------------------------------------------------------------------- 15

9 Accessories ------------------------------------------------------------------------------------------------- 15

10 Transportation and Storage -------------------------------------------------------------------------- 16

11 Quality Warranty --------------------------------------------------------------------------------------- 16