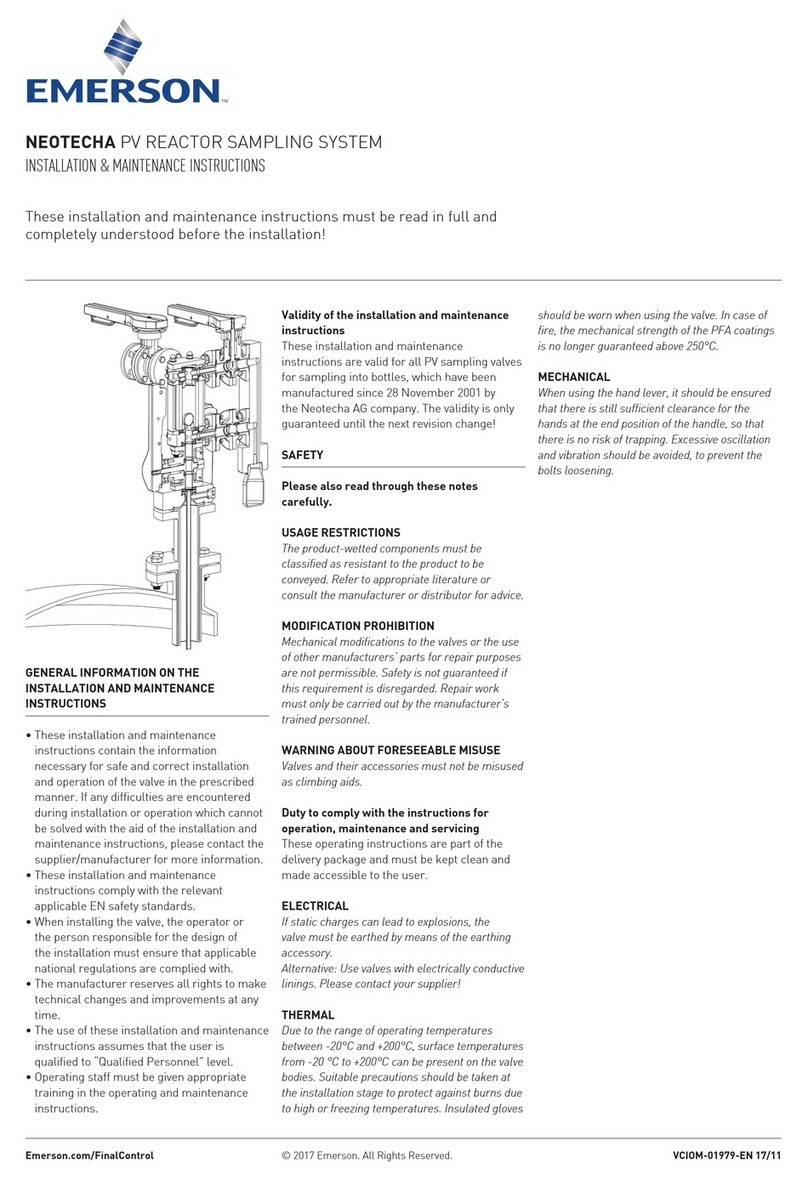

Ytc YT-700 Series User manual

SOLENOID VALVES PRODUCT MANUAL

YT-700 SERIES

VERSION 1.02

2 YT-700 series

Contents

1. Introduction …………………………………………………………………………………………… 3

1.1 General information for the users ………………………………………………………………. 3

1.2 Manufacturer Warranty …………………………………………………………………………… 3

1.3 Explosion Proof Warning ……………………………………………………………………….. . 3

2. Product Description ………………………………………………………………………………….. 4

2.1 General …………………………………………………………………………………………….. 4

2.2 Main Features and Functions ……………………………………………………………………. 4

2.3 Label Description ………………………………………………………………………………….. 4

2.4 Product Number …………………………………………………………………………………… 5

2.5 Product Specification ……………………………………………………………………………… 5

2.6 Parts andAssembly – YT-700S (3 way)………………………………………………………….. 6

2.7 Parts andAssembly – YT-700D (4 way) ……………………………………………………..…. 6

2.8 Operation Logic – YT-700S (3 way)………………………………………………………………. 7

2.9 Operation Logic – YT-700D (4 way) ………………………………………………………………. 7

2.10 Dimension – YT-700S (3 way) ……………………………………………………………………. 8

2.11 Dimension – YT-700D (4 way) ……………………………………………………………………. 9

3. Installation ………………………………………………………………………………………………. 9

3.1 Safety ……………………………………………………………………………………………….. 9

3.2 Manual Switch……….. …………………………………………………………………………… 10

4. Connection ...……………………………………………………………………………………..…… 10

4.1 Safety ……….……….. …………………………………………………………………………… 10

4.2 Supply Pressure Condition ………………………………………………………………………. .10

4.3 Piping Condition …………………………………………………………………………………… 11

4.4 Connection – Actuator ……………………………………………………………………………...11

4.5 Connection – Power ………………………………………………………………………...…….. 12

5. Maintenance……………………………………………………………………………………………. 12

6. Trouble-Shooting ………………………………………………………………………………………. 13

3 YT-700 series

1. Introduction

1.1 General Information for the users

Thank you for purchasing Young Tech Co., Ltd products. Each product has been fully

inspected after its production to offer you the highest quality and reliable performance.

Please read the product manual carefully prior to installing and commission the product.

For the safety, it is important to follow the instructions in the manual. Young Tech Co.,

Ltd will not be responsible for any damages caused by user’s negligence.

The manual should be provided to the end-user.

Any modifications or repairs to the product may only be performed if expressed in this

manual.

The manual can be altered or revised without any prior notice. Any changes in

product’s specification, design, and/or any components may not be printed immediately

but until the following revision of the manual.

The manual should not be duplicated or reproduced for any purpose without prior

approval from Young Tech Co., Ltd, Gimpo-si, South Korea.

1.2 Manufacturer Warranty

For the safety, it is important to follow the instructions in the manual. Manufacturer will

not be responsible for any damages caused by user’s negligence.

Manufacturer will not be responsible for any damages or accidents as a result of any

alteration or modification of the product and its parts. If any alteration or modifications

are necessary, please contact Young Tech Co., Ltd directly.

Manufacturer warrants the product from the date of original purchase of the product for

one (1) year, except as otherwise stated.

Manufacturer warranty will not cover products that have been subjected to abuse,

accidents, alterations, modifications, tampering, negligence, misuse, faulty installation,

lack of reasonable care, repair or service in any way that is not contemplated in the

documentation for the product, or if the model or serial number has been altered,

tampered with, defaced or removed; damages that occurs in shipment, due to act of

God, failure due to power surge, or cosmetic damage. Improper or incorrectly

performed maintenance will void this limited warranty.

For detailed warranty information, please contact Young Tech Co., Ltd – South Korea.

1.3 Explosion Proof Warning

Please ensure the unit is being used and installed within the explosion proof certified

environment.

YT-700 series explosion proof grades are Ex d IIC T6 and can be used in zone 1.

Explosion proof type of cables and gaskets should be used, when explosion gases are

4 YT-700 series

present at the installation site.

Power should be turned off completely when opening product’s cover. When opening

the cover, ensure that there is no power remaining in any electrical parts nearby.

Blind plug is required when any port is not being used.

Flameproof certified sealing fitting and/or cable glands must be used. Power cable

must be at least 1mm2or 18AWG.

For external ground terminal, cable rug with surface area of more than 5.5mm2should

be used.

2. Product Description

2.1 General

Solenoid valve, YT-700 series, given AC or DC electric signal, outputs supply air pressure to

valve or changes the output port direction.

2.2 Main Features and Functions

Designed to be Ex d IIC T6 explosion proof grade.

Easy replacement of coil as both AC and DC type use same enclosure.

Can test the operation in manual switch without power source.

High durability as valve body is pneumatic pressure operating type.

Can be directly mounted on an actuator. (NAMUR design)

2.3 Label Description

Fig. 1: YT-700 Body Label

A. Model: Indicates the model number

B. Explosion Proof: Indicates certified explosion proof grade.

C. Air Supply (Max).: Indicates maximum supply pressure

D. Rating: Indicates allowable voltage.

5 YT-700 series

2.4 Product Number

2.5 Product Specification

Model YT-700

Valve Type 3 Way 4 Way

Max Sup. Pressure 0 ~ 0.4 Mpa

0 ~ 0.7 Mpa 0.1 ~ 1.0 Mpa

Flow Capacity

(Cv)

Output 0.2 (3 pie) at 0.4 Mpa 0.75

0.084 (1.6 pie) at 0.7 Mpa

Exhaust 0.093 N/A

Rating

AC 220V 9.5W (51mA) 13.5W (61mA)

AC 110V 4.8W (57.8mA) 14.5W (130mA)

DC 24V 3.8W (158mA) 13.5W (560mA)

Frequency 50 ~ 60 Hz

Explosion Proof Ex d IIC T6

Connection Type PT / NPT 1/4

Conduit Entry PF 1/4 (G1/2)

Coil Insulation Grade Class B

Ambient Temp. Operating -20 ~ 70’C

Explosion -20 ~ 50’C

Weight 0.8 kg (1.8 lb) 0.9 kg (2.0 lb)

6 YT-700 series

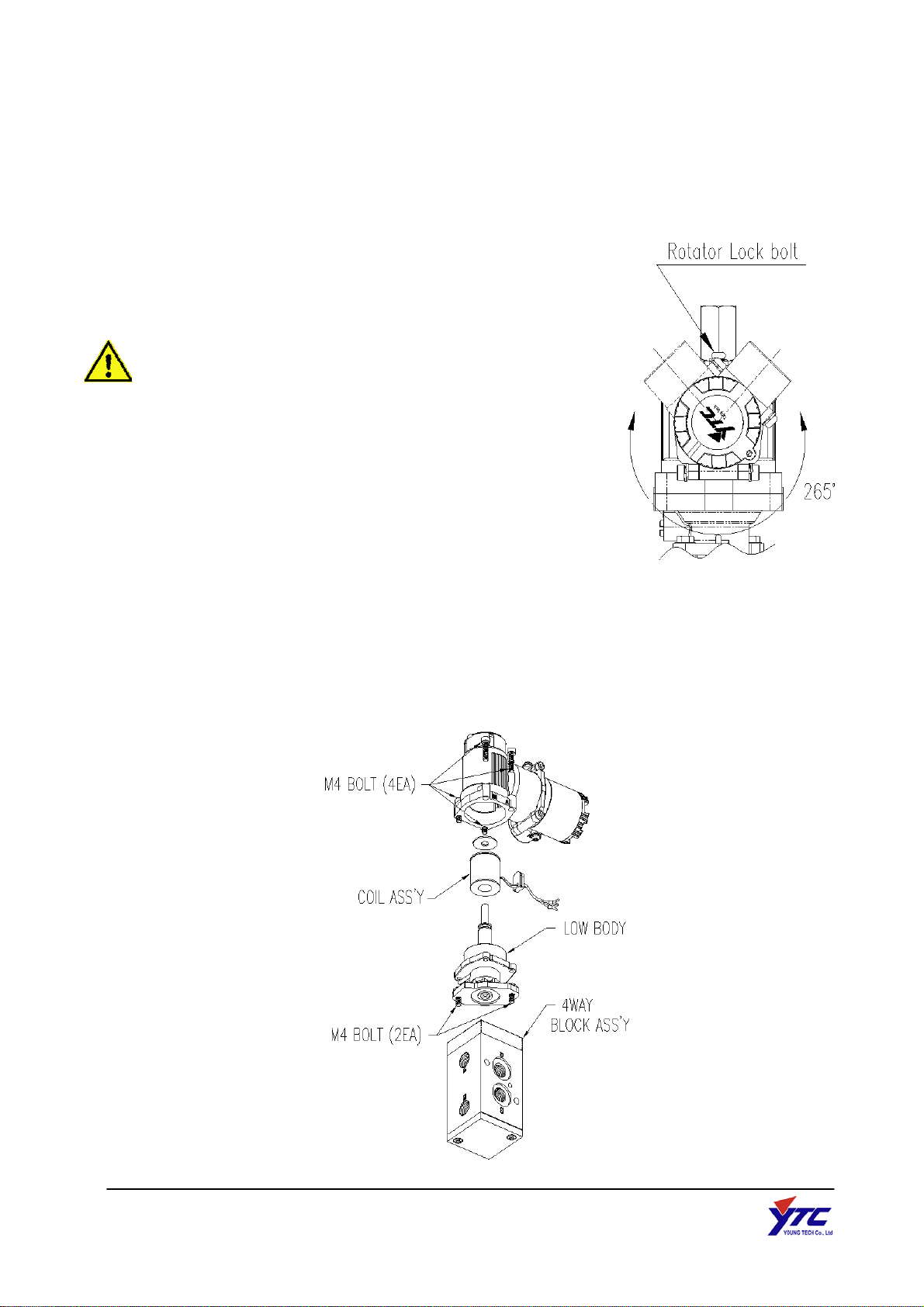

2.6 Parts andAssembly – YT-700S (3 way)

2.7 Parts andAssembly – YT-700D (4 way)

7 YT-700 series

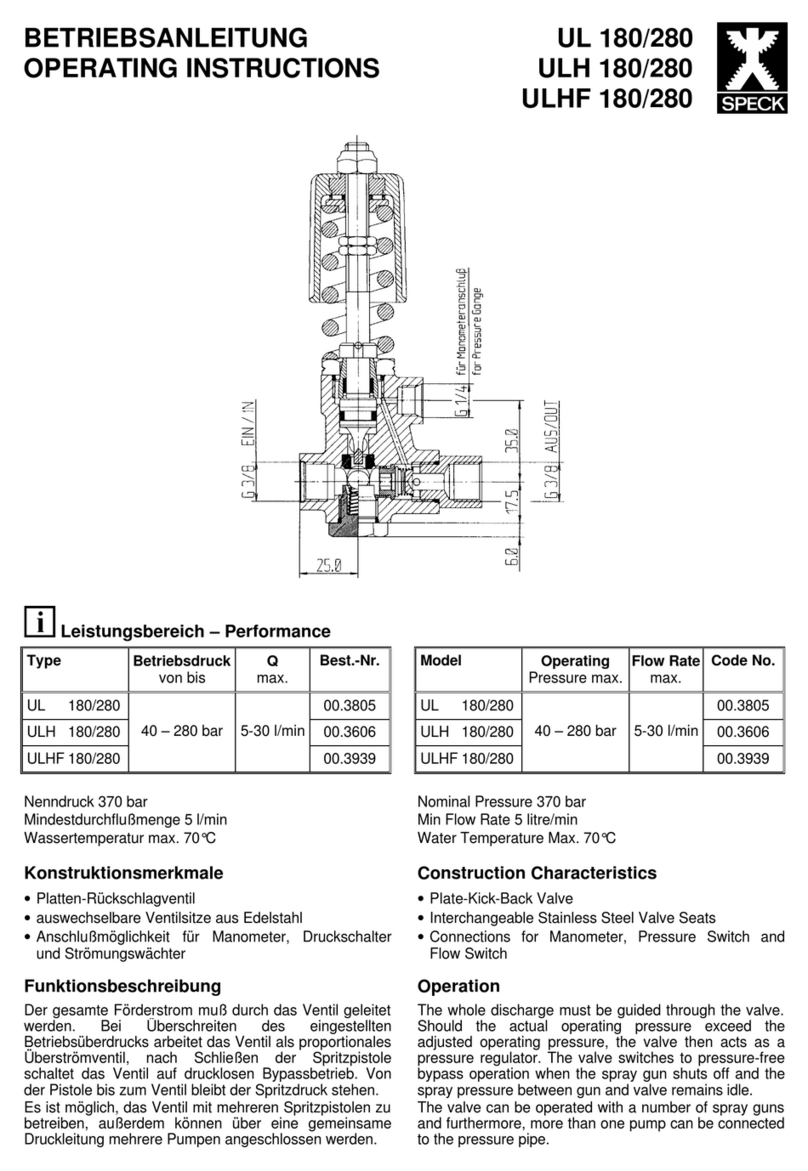

2.8 Operation Logic – YT-700S (3 way)

As signal pressure is being supplied, the plunger (○

6) rises and creates secondary a gap

between the nozzle (○

9) and plunger (○

6) which results primary air pressure exhaustion.

When signal pressure has been turned off, the plunger (○

6) moves downward and blocks the

channel. At the same time, the air pressure will exhaust through the channel between the

plunger (○

6), vent (○

2), and body cap (○

1).

2.9 Operation Logic – YT-700D (4 way)

As signal pressure is being supplied, plunger (○

6) rises and creates a gap between the

nozzle (○

9) and plunger (○

6) which results primary air pressure to push down the spool (○

11 )

and exhausts air to OUT2 (C2). When signal pressure has been turned off, the plunger (○

6)

moves downward and blocks the channel. At the same time, air pressure pushes spool (○

11 )

upward and exhausts air to OUT1 (C1).

8 YT-700 series

2.10 Dimension – YT-700S (3 way)

9 YT-700 series

2.11 Dimension – YT-700D (4 way)

3. Installation

3.1 Safety

When installing a unit, please ensure to read and follow safety instructions.

Check unit’s specification and ensure to use as specified.

Follow other explosion proof procedures and safety precautions.

Use bypass valve or other supportive equipment to avoid entire system “shut down”.

YT-700 series is designed for explosion area.

Make sure all input and supply pressure to valve, actuator, and other related devices

must be turned off.

10 YT-700 series

3.2 Manual Switch

The manual switch can be adjusted by hand or by screw

driver (-). At the manual position (M), the valve can be

opened without power supply. At the automatic position (A),

the valve can be operated per input signal. DO NOT TURN

THE MANUAL SWITCH WITH FORCE, AS IT CAN BE

DAMAGED.

For YT-700D (4 way), the air channel will be switched as

below.

4. Connections

4.1 Safety

Supply pressure should be clean and dry air – avoiding moisture, oil or dust.

Always recommended to use air filter regulator (i.e. YT-200 series).

Young Tech Co., Ltd has not tested positioner’s operation with any other gases other

than clean air. Please contact Young Tech Co., Ltd for any questions.

4.2 Supply Pressure Condition

Dry air with at least 10℃lower than ambient temperature.

Avoid from dusty air. Positioner’s inner filter can only filter 5 micron or larger.

Avoid oil.

Comply with ANSI/ISA-57.3 1975(R1981) or ISA S7.3-1975(R1981).

Supply pressure range is 1.4 ~ 7 kgf/cm2(140-700 kPA)

Set air filter regulator’s pressure level 10% higher than actuator’s spring range pressure.

11 YT-700 series

4.3 Piping Condition

Ensure inside of pipe is clean of obstructions.

Do not use pipeline that is squeezed or shows any type of damamges.

Pipeline should have more than 6mm of inner diameter (10mm outer diameter) to

maintain flow rate.

The length of pipeline system should not be extremely long. Longer pipeline system

may affect flow rate due to the friction inside of the pipeline.

4.4 Connection – Actuator

YT-700 series can be installed with or without a bracket.

4.4.1 YT-700S (3 way)

4.4.2 YT-700D (4 way)

12 YT-700 series

4.5 Connection – Power

4.5.1 Safety

When installing in hazardous and explosive gas area, conduit tube or pressure-proof

packing union must be used. The compound charging

box should be the flameproof type and must be sealed

completely.

Conduit entry connection tap is PF 1/2 or G 1/2.

Before connecting terminal, ensure that the power is off

completely. Do not open the cover when the power is

still alive.

Please use twisted cable with conductor section are

1.25mm2and that is suitable for 600V (complying to the

conductor table of NEC Article 310.) The outer diameter

of the cable should be between 6.35 ~ 10mm. Use shield

wire to protect against electro-magnetic field and noise.

Please do not install the cable near high noise equipment -

such as high-capacity transformer or motor.

5 Maintenance

Two parts can be replaced – coil assembly and valve. Parts can be replaced easily at the field;

however, when performing maintenance in hazardous and explosive gas area, please follow

safety precautions. For YT-700 series, only

coil assembly can be changed.

13 YT-700 series

6 Trouble-Shooting

Please follow trouble-shooting when the product is not functioning properly.

No response from the plunger after input signal has been supplied.

Please check if input signal is correct voltage.

Please check the resistance between (+) and (-) poles. If the resistance is too high,

the coil can be burned.

Plunger operates but no exhaust when input signal has been supplied.

Please check if supply pressure from the regulator is stable.

Please check if regulator pressure is too low.

Please check if exhaust port has been blocked.

Air pressure exhausts when there is no input signal.

Please check if switch is at automatic (A) position.

Please check if regulator pressure is too low.

14 YT-700 series

Manufacturer:

Young Tech Co., Ltd

#3022, Hagun-ri, Yangchon-myeon

Kimpo-si, Kyeonggi-do, 415-843

South Korea

Tel: +82-31-986-8545

Fax: +82-31-986-2683

Email: [email protected]

Copyright © Young Tech Co., Ltd. All Rights Reserved.

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

Honeywell

Honeywell 7800 SERIES Product data

Alpha

Alpha XMP-8D installation instructions

Satel

Satel MICRA quick start guide

Lefroy Brooks

Lefroy Brooks CB-2675 Installation, operating, & maintenance instructions

UNI Geräte

UNI Geräte EVSA Operating and maintenance instructions

Acromag

Acromag BusWorks XT Series user manual