– 1 –

Yuasa began development of the NP series of valve

regulated lead acid batteries in 1958. Today’s NP battery

is the culmination of over 75 years of battery

manufacturing experience.

•Sealed Construction . . . . . . . . . . . . . . Yuasa’s unique construction and sealing technique ensures that no electrolyte

leakage should occur from the terminals or case of any NP battery. This

feature provides for safe and effective operation of NP batteries in any

orientation. Yuasa NP batteries are classified as “Non-Spillable” and meet

all requirements of the International Air Transport Association. (I.A.T.A.

Dangerous Goods Regulations), to allow transportation by air.

•Electrolyte Suspension System All Yuasa NP batteries utilise an electrolyte suspension system consisting of

a glass fibre separator material. This suspension system helps to achieve

maximum service life, by fully retaining the electrolyte and preventing its escape

from the separator material. No silica gels or other contaminents are used.

•Gas Generation . . . . . . . . . . . . . . . . . NP batteries incorporate a unique Yuasa design that effectively recombines

over 99% of the gas generated during normal usage.

•Low Maintenance Operation . . . . . . . During the life of NP batteries, there is no need to check their specific gravity

or add water etc. In fact, there are no provisions for such maintenance

functions to be carried out.

•Operation In Any Orientation . . . . . . The combination of sealed construction and Yuasa’s electrolyte suspension

system permits operation of NP batteries in any orientation (excluding continuous

inverted use) without loss of capacity, electrolyte, or service life. The NP batteries

made in our factory in Wales also conform to BS EN61056-1 (1993) and IEC 1056-

1 (1991).

•Low Pressure Venting System . . . . . Yuasa NP batteries are equipped with a safe, low pressure venting system,

which is designed to release excess gas and reseal automatically in the event of

the internal gas pressure rising to an unacceptable level. This low pressure

venting system, coupled with the significantly high recombination efficiency,

make Yuasa NP batteries one of the safest valve regulated lead acid batteries

available.

•Heavy Duty Grids . . . . . . . . . . . . . . . The heavy duty lead calcium alloy grids in NP batteries provide an extra

margin of performance and service life in both float and cyclic applications,

even in conditions of deep discharge.

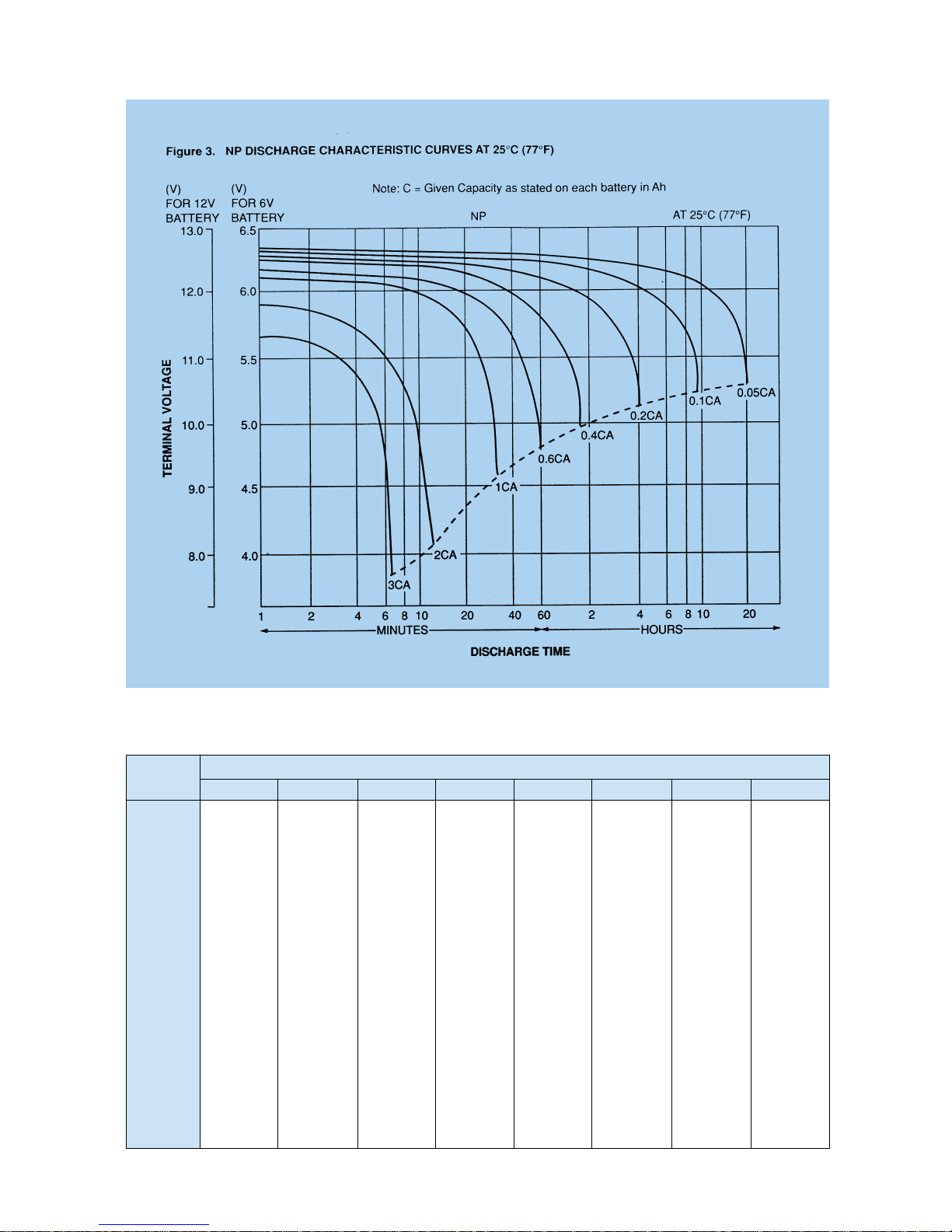

•Cyclic Service Life . . . . . . . . . . . . . . . Depending upon the average depth of discharge, over 1,000 discharge/

recharge cycles can be expected from NP batteries.

•Float Service Life . . . . . . . . . . . . . . . . . The expected service life of the standard model NP battery when used in stand-

by applications is typically 5 years; however, experience has shown that their

service life often exceeds 6 years, if the NP batteries are operated strictly within

specification.

ADVANCEMENTS

The high energy density, advanced plate technology,

sealed construction, efficient performance and long

service life combine to make Yuasa NP batteries the most

reliable and versatile valve regulated lead acid batteries

available.

With the progress of modern technology and the specific

development of application requirements, Yuasa has

designed generic NP’s to be application specific with the

introduction of NPC, NPH and NPL product ranges.

NPC is specifically designed to suit the arduous require-

ments of cyclic applications allowing increased cycle life (at

least double the cyclic life of conventional types).

NPH These high performance batteries are specifically

designed for applications requiring high rate discharge and

offer much improved power densities up to 50% more

watts per kilo than conventional NP models when operated

at the 10 minute discharge rate.

NPL Offers up to double the float service life of the conven-

tional NP type battery. Note, these models are available to

BS6290pt4 (1997).

The generic types utilise identical physical designs and

characteristics to the standard NP type in all aspects except

their specific application advancement. This in many cases

allows users to upgrade without major redesign.

INTRODUCTION

TECHNICAL FEATURES