Zanussi PW64 User manual

Other Zanussi Hob manuals

Zanussi

Zanussi ZGF 7820 User manual

Zanussi

Zanussi ZGA 75 W User manual

Zanussi

Zanussi ZAF 42 User manual

Zanussi

Zanussi GAS HOB ZGF 681 User manual

Zanussi

Zanussi ZDB310 User manual

Zanussi

Zanussi ZEM8740FBA User manual

Zanussi

Zanussi ZKT 641 LX User manual

Zanussi

Zanussi ZKT663 User manual

Zanussi

Zanussi ZGNE645K User manual

Zanussi

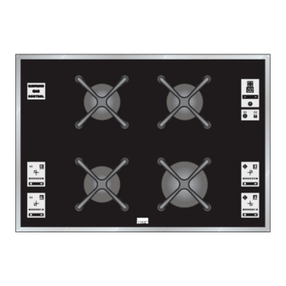

Zanussi ZGG 743 EX User manual

Zanussi

Zanussi ZGF 991 User manual

Zanussi

Zanussi ZGH62412BA User manual

Zanussi

Zanussi ZEE6140 User manual

Zanussi

Zanussi ZHRN641K User manual

Zanussi

Zanussi ZKT 622 HN Specification sheet

Zanussi

Zanussi ZGL62IT User manual

Zanussi

Zanussi ZGS 782 ICT User manual

Zanussi

Zanussi ZGS 322 User manual

Zanussi

Zanussi ZGF782C User manual

Zanussi

Zanussi ZHRN642K User manual

Popular Hob manuals by other brands

dipo INDUCTION

dipo INDUCTION DIBK218S quick start guide

Miele

Miele KM 5987 Operating and installation instructions

Miele

Miele KM 360 G installation instructions

Blomberg

Blomberg MKN 24201 W user manual

Progress

Progress PAI3101F user manual

Hotpoint Ariston

Hotpoint Ariston PKL 641 IX/HA operating instructions