Series 3 Technician’s Installation and Service Training Manual

Understanding How ZAP Commercial Operators Work

Series 3 Technician’s Installation and Service Training Manual

Understanding How ZAP Commercial Operators Work

Series 3 Understanding How ZAP Commercial Operators Work

ZAP Series 3

Simply Logical

ZAP Controls

100 Waterloo Blvd. Anglesey Business Park, Littleworth Road, Cannock, Staffordshire, England

UK Contact 011-44-154-387-9444 sales@zap-uk.com

USA Contact 931-510-4432 sales@zap-america.com

USA Tech Support 931-510-4432 via telephone or text

Online www.zap-uk.com

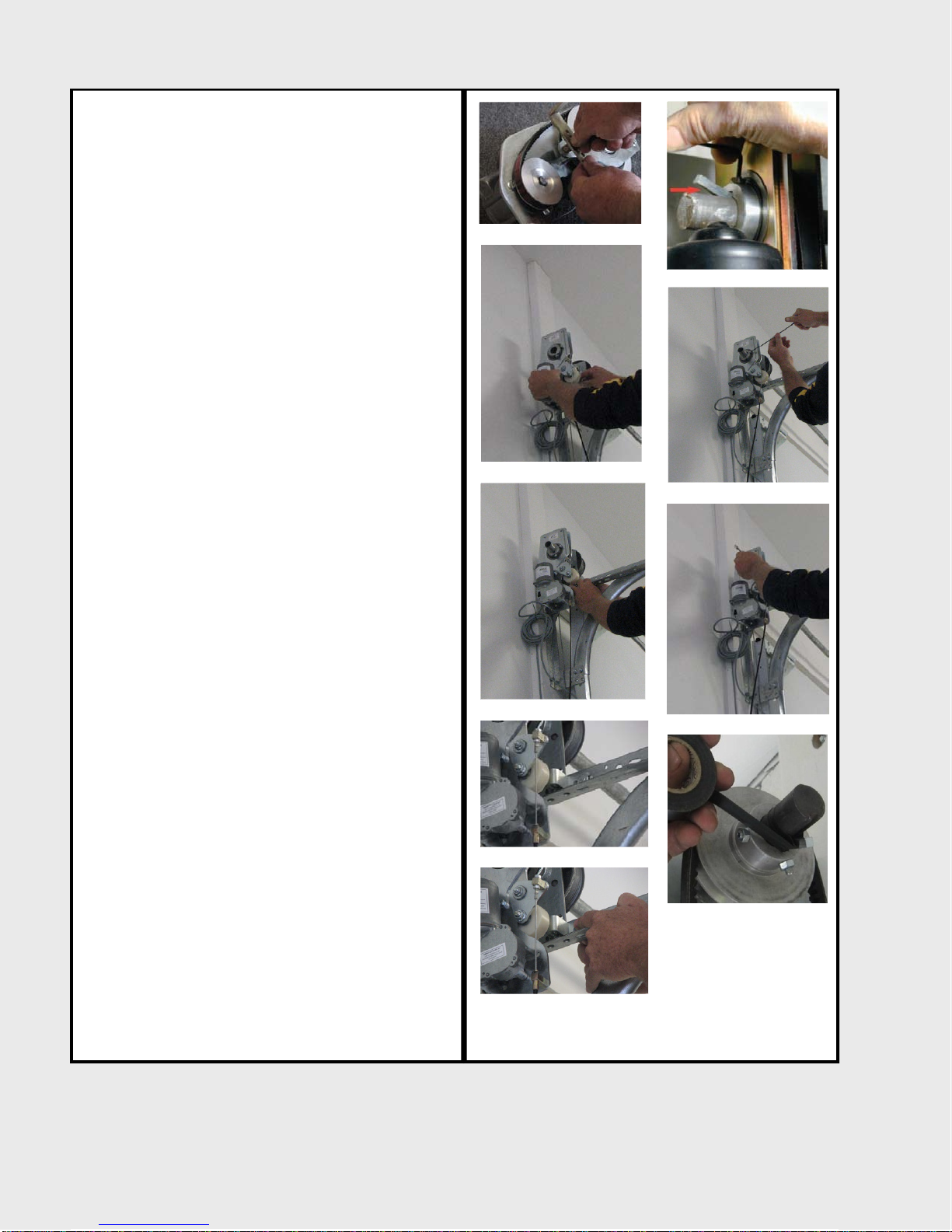

Unlike traditional operators, ZAP

operators do not have limit

assemblies.

ZAP operators use a 21st

century technology, that uses

runtime calibration and current

sensing technology to perform the functions of limit

assemblies.

The limits of the door operator are

physical in nature.

The floor being the down limit.

(Figure A)

A physical stop for the upper limit.

On standard lift and low headroom

doors the physical stop is the track

radius as the door can only rise so

high into the radius before the

torsion shaft would have to counter

rotate to allow the door to go

higher. (Figure B)

On high-lift and vertical lift doors it

should be a bumper or pusher

spring. (Figure C)

The controller monitors the motor

load current. It therefore becomes a sensor that

automatically detects the door limits as well as

obstructions that can occur without the use of an

aftermarket safety edge. Because of its unique

abilities it can detect an obstructions on any part of

the door, not just the leading door edge.

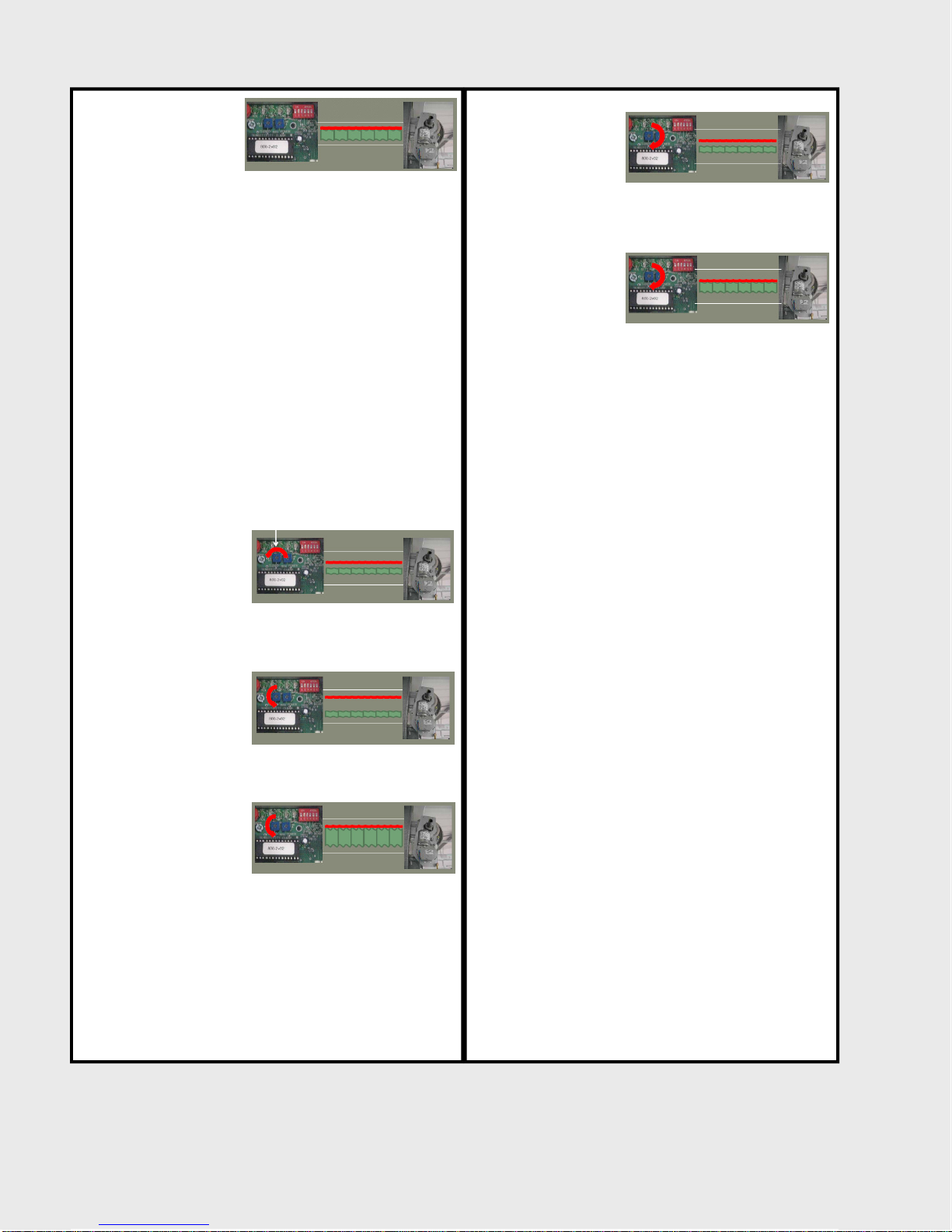

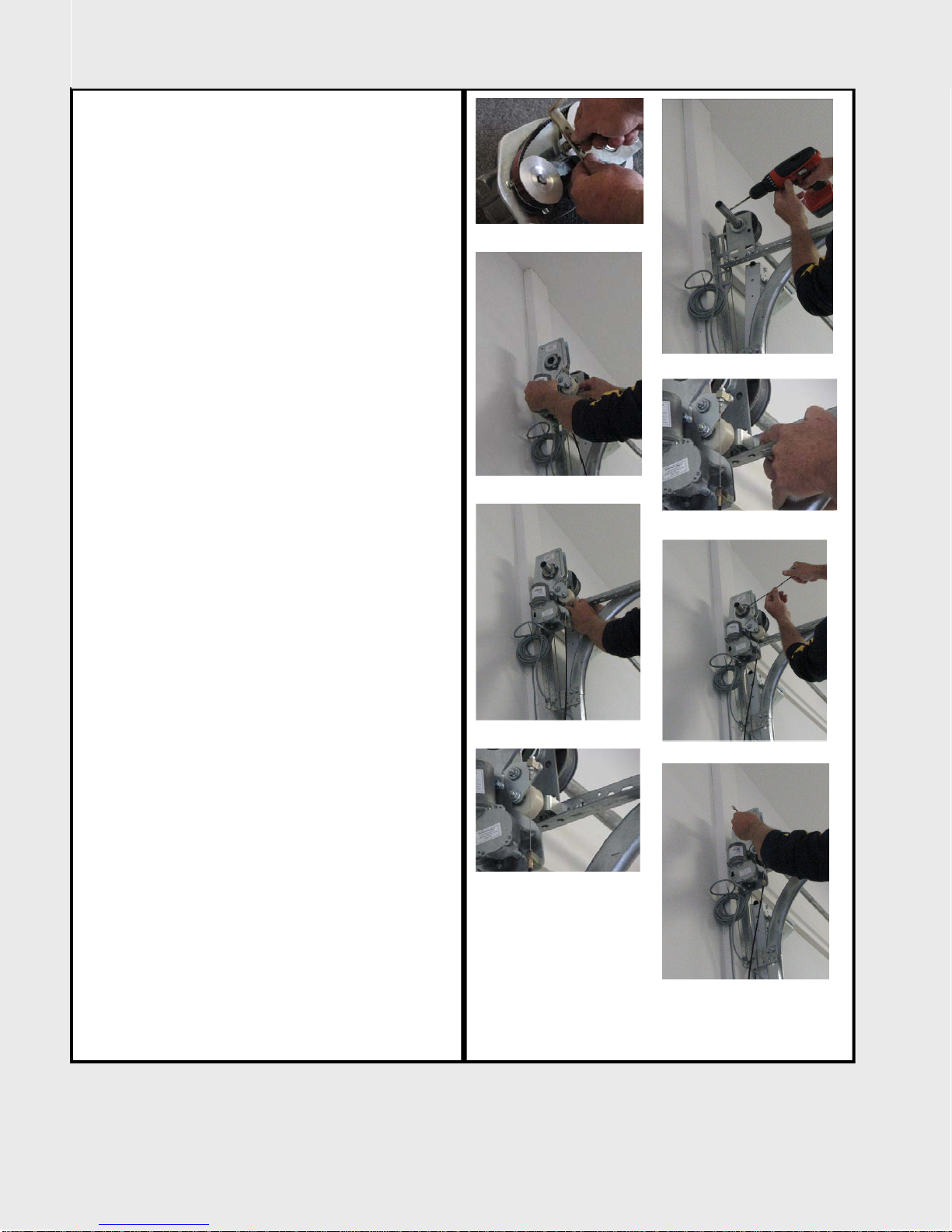

Speed Change Point Calibration.

Calibration of slow speed change point is needed to

determine an approximation of the physical limits.

During the initial open calibration cycle, the

controller is measuring the run time to the upper

limit.

Approximately half way through the first open cycle

of operation, note that the operator will slow down.

This slow down is called a speed change point. After

completing the first up cycle, the run time to the

upper limit is stored into memory. The same thing

occurs on the close calibration cycle. Approximately

half way through the first close cycle of operation,

the operator will again slow down. After completing

the first close cycle, the close run time is stored into

memory as well and is compared to the open run

time.

During the second calibration run, the run times

are verified against the first set of run times. If

they match, they are stored into memory. It takes

2-3 complete cycles to fully calibrate the run time.

Once the operator has fully calibrated the run

times, the controller moves the opening speed

change point to within seconds of the end of the

calibrated open run time. Likewise, the controller

moves the closing speed change point to within

seconds of the end of it’s calibrated run time. This

is how the controller knows where the limits are

and where to stop.

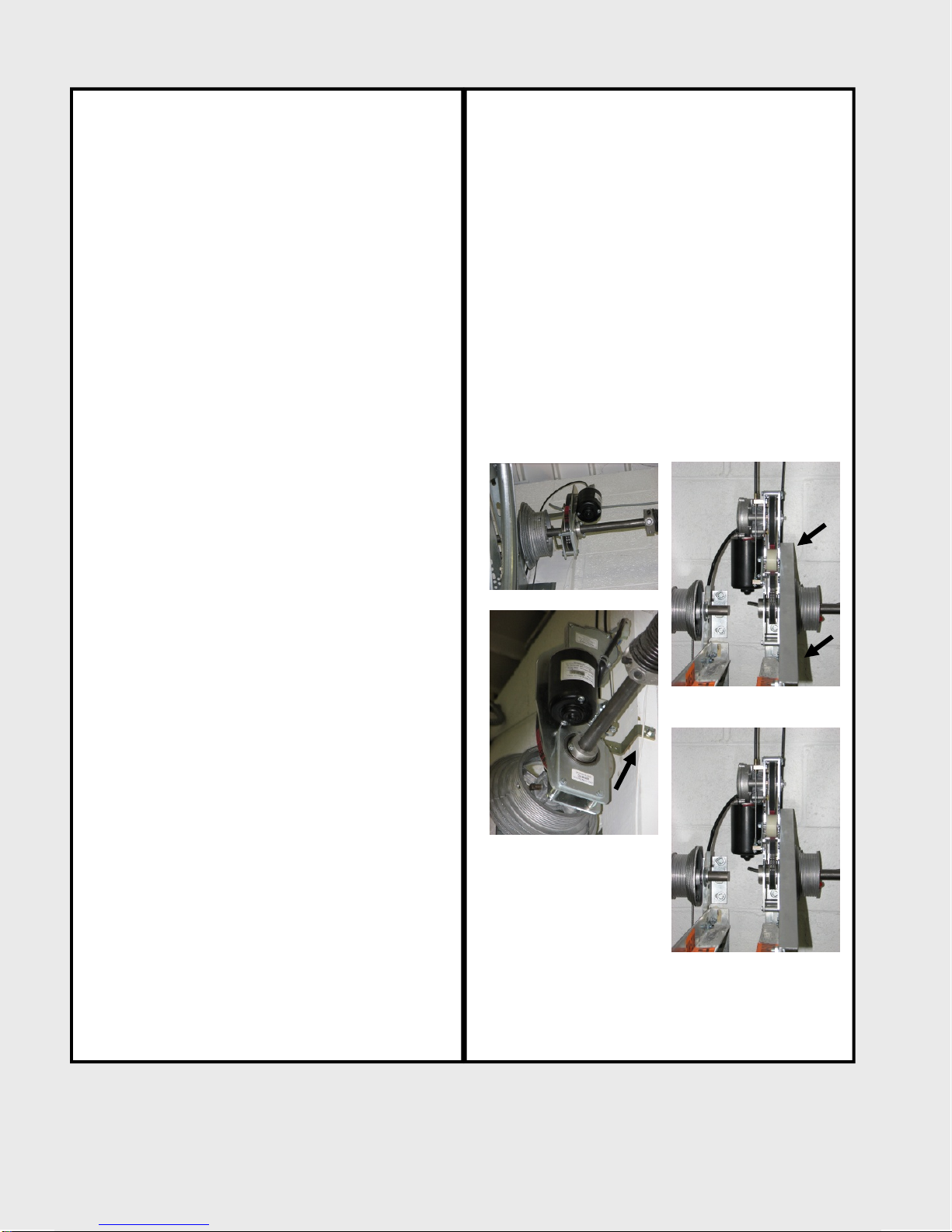

Motor power and sensitivity potentiometer,

obstruction sensing, automatic reversing and

safety stop.

Picture if you will,

current flowing to the

motor.

(Figure D)

If you increase power

at the power

potentiometer you

open up the range of

power that can be

applied to the motor.

(Figure E)

If you decrease power

at the power

potentiometer it

closes the range of

power that can be

applied to the motor. (Figure F)

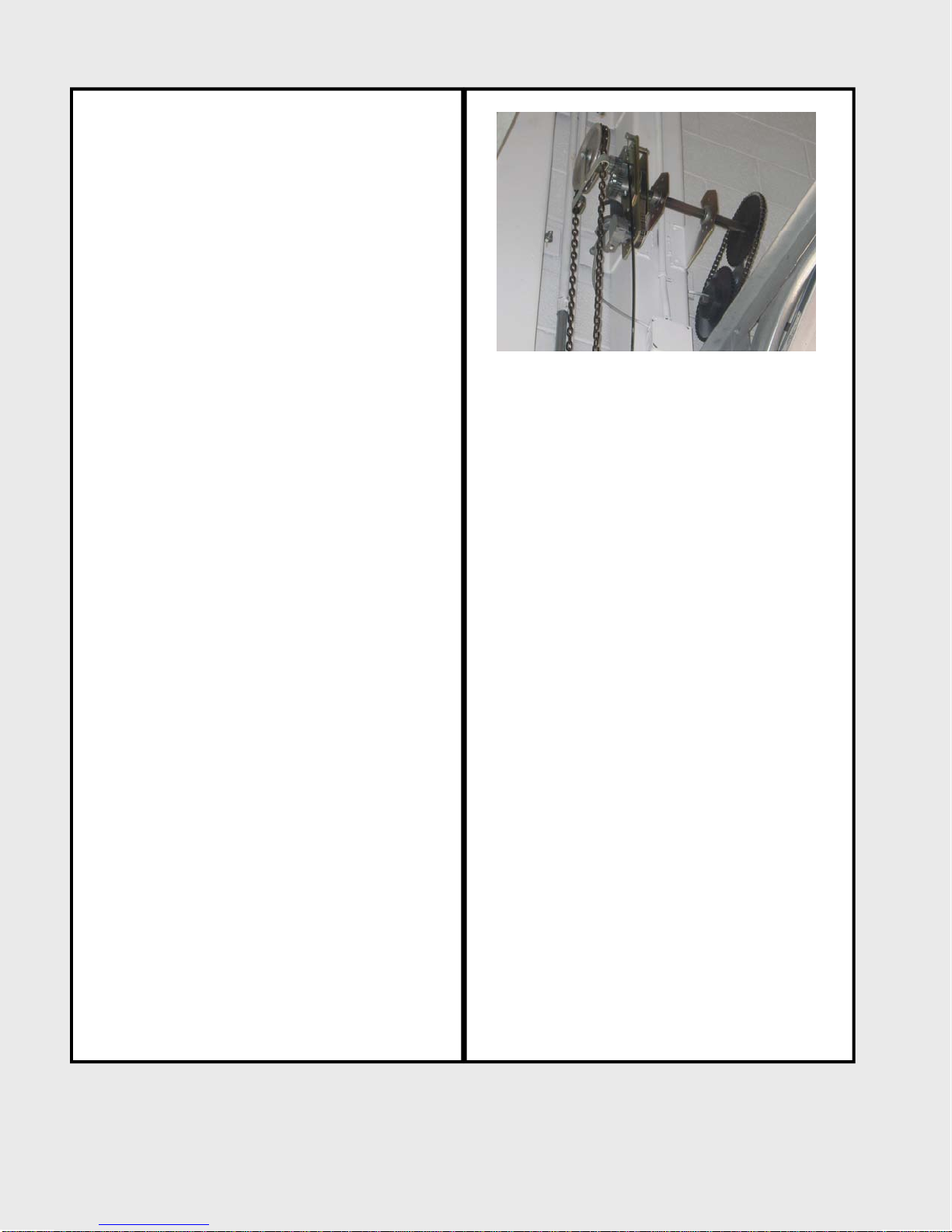

Inherent safety functions

Stop at limit, safety stop, and automatic reversing

The inherent safety

and sensitivity

function’s monitor the

system by mirroring

the motor current. If

the door meets an

obstruction in either direction, the current spikes.

(Figure F)

Continued on next page.

Figure C

Figure B

Figure F

Figure D

Figure E

Figure A

Figure F

4