3

1 Safety First

1.1 Introduction

Read this instruction manual carefully.

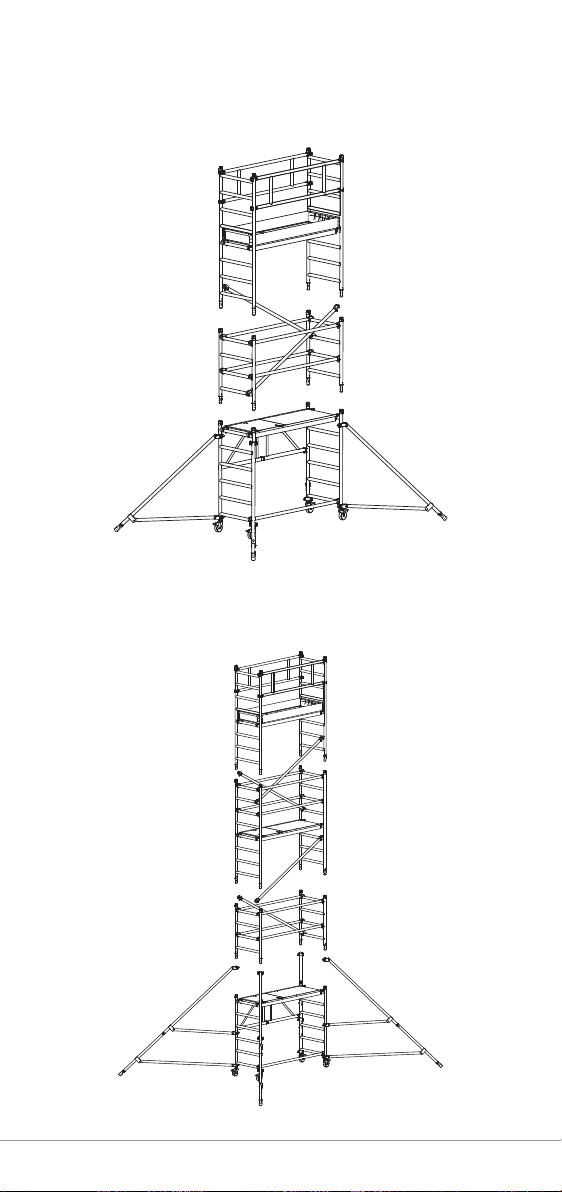

Note that diagrams are for illustrative purposes only.

Instruction manuals are also available to download from our

website at zarges.com/uk.

PAXTower mobile aluminium towers are light-weight scaffold

towers used throughout the building and construction industry

for both indoor and outdoor access solutions where a stable

and secure platform is required. Ideal for maintenance and

installation work or short-term access, the highly versatile

towers provide a strong working platform for a variety of

heights.

This instruction manual provides you with step by step

instructions to ensure your system is erected easily and safely,

using the 3T (Through The Trapdoor) method. The law requires

that personnel erecting, dismantling or altering towers must

be competent. Any person erecting a mobile tower must have

a copy of this instruction manual. For further information

on the use of mobile access and working towers consult the

PASMA operators code of practice.

If you need further information, design advice, additional

instruction manuals or any other help with this product,

please contact the manufacturer on +44 (0)1908 641118 or

email sales@zarges.co.uk.

1.2 Compliances

The PAXTower 3T aluminium towers have been

tested and certified to EN 1004.

1.3 Preparation and inspection

Inspect the equipment before use to ensure that it is not

damaged and that it functions properly. Damaged or incorrect

components should not be used.