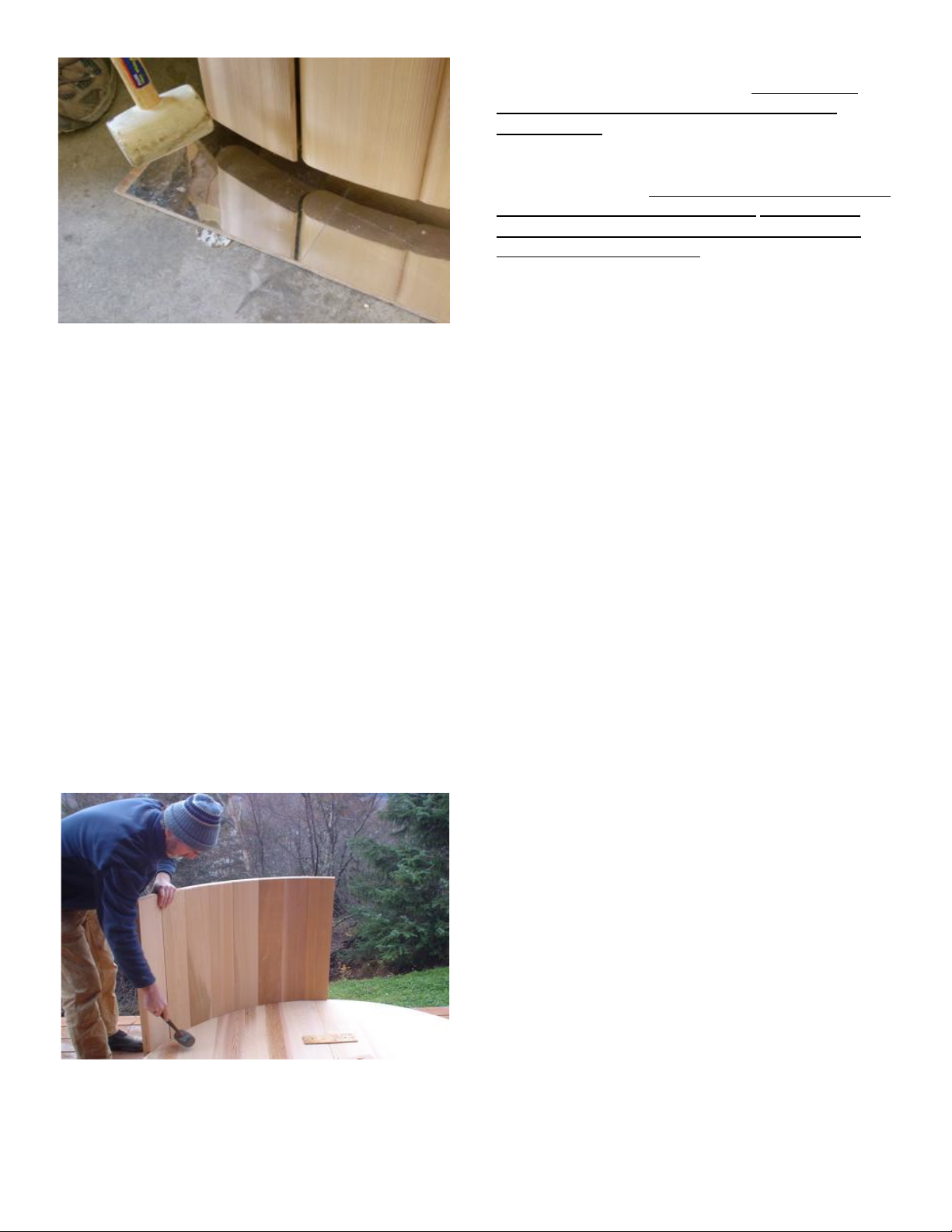

bottom, directly over the dado, until it just meets the

pencil line that has been scribed about 9/16” from the

edge of the top of the tub floor.

The stave should then stand on its own from the friction

of the tapered joint. The amount of force to use at this

point is moderate - just enough to get the stave to bite the

floor enough to stand on its own. Don’t worry - you’ll get

to hit them harder soon!

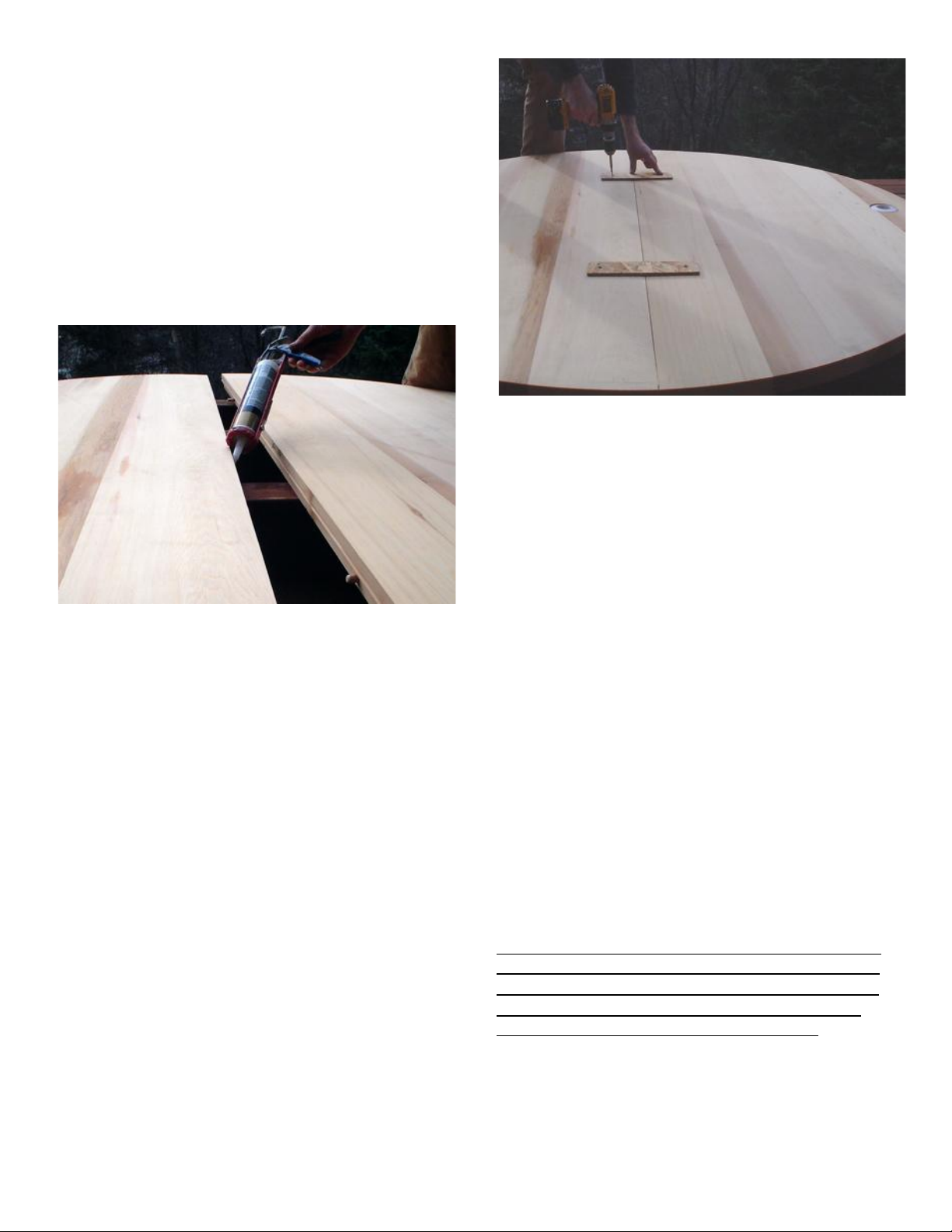

Figure 6.1 Floor seams should be straddled by staves to

ensure the tub will seal.

NOTE: 4’elliptical tub has one piece floor and no floor

seam, all others have either 1 or 2 seams.

AS YOU PROCEED - Check the edges of each stave

and remove any dirt or wood particles that could

interfere with a good seal.

VERY IMPORTANT! Use of the small mirror

included in the kit: A reflective mirror approximately 4”

x 10” is used to see what is happening on the bottom of

the staves. The mirror may have a protective plastic sheet

over the reflective surface – Peel this layer off. Place the

mirror on the ground directly under the staves you are

adding. Use it to observe how tight and consistent the

gap is between staves. Use the mirror and mallet to adjust

this gap to keep it tight and consistent as you proceed.

Now work aerial view clockwise (to your left) and add a

second stave next to the first. Proceed with stave #2 going

clockwise around the tub (from aerial view), and so on.

NOTE: Proceeding in a clockwise direction is important

as it allows you to tap on the bead edge (convex edge) of

the staves with the mallet and not the fragile cove edge

(concave edge).

We have arranged the suction and jet staves in a standard

layout that makes installing the plumbing and benches as

easy as possible and is based on keeping the span with

plumbing minimized while still allowing for effective

plumbing installation and use. If a different plumbing

layout is desired, you can certainly install the staves out

of order as necessary. Retaining the factory order of the

staves will minimize the slight differences in stave

heights, causing the rim to not be perfectly smooth.

However some slight differences will still be present.

Placing the staves out of order may slightly increase these

height differences. Either way, you may wish to sand the

top rim again after you have installed and tightened the

retention bands. However, this does not affect tub

function or longevity, but rather is a cosmetic option.

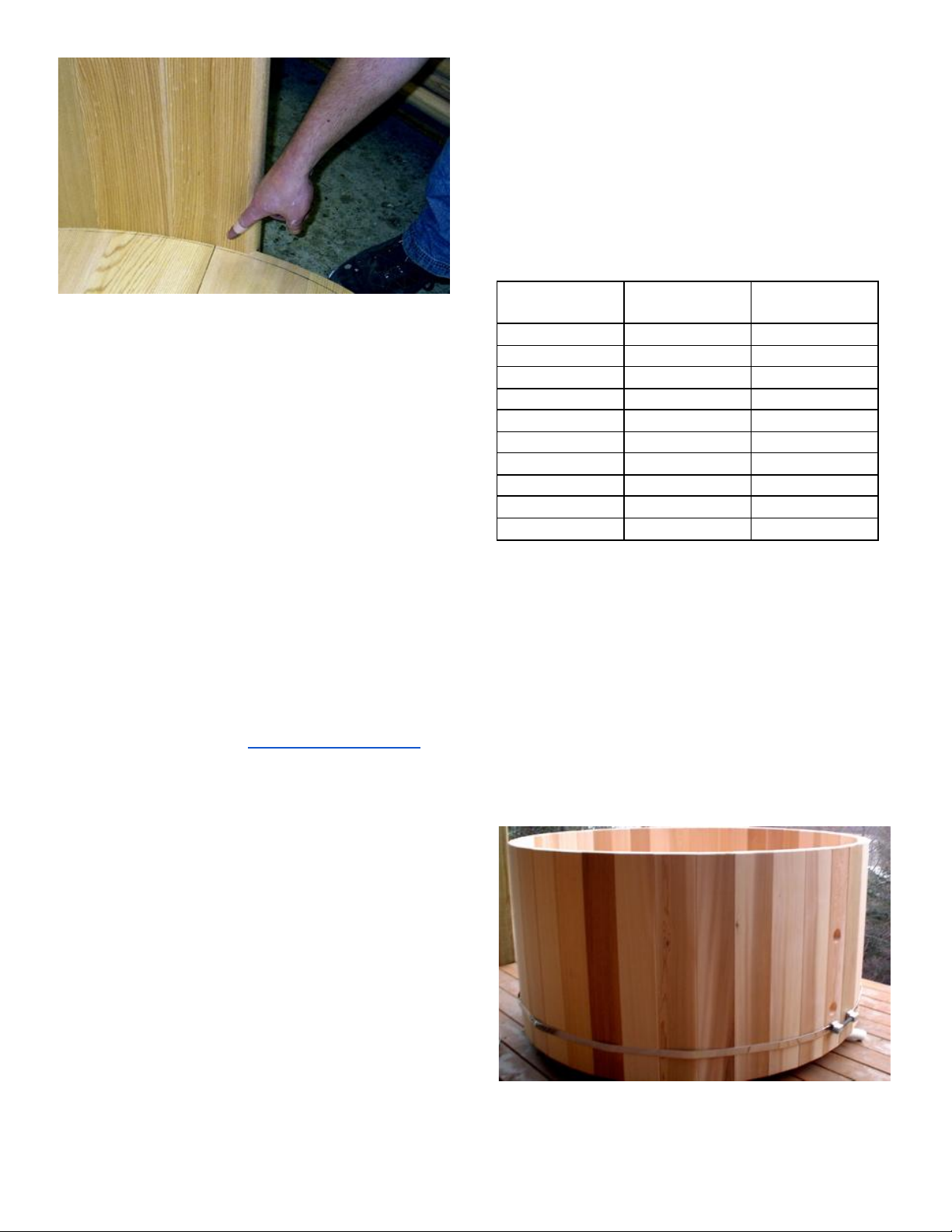

DO NOT put silicone between the staves. Use the mallet

to gently tap each new stave first sideways - mating the

convex “bead” edge (ball) and convex “cove” edge

(socket) - until snug with the first stave inside and out,

then tap it inward gently until it stays in place on its own.

Remember you should be working towards your left

(clockwise from aerial). This ensures you are placing

each new stave, cove edge first. Tap the staves only on

the bead edge, NOT the cove edge which is more fragile

and could be damaged by the mallet. Add the third stave

the same way - always snug them tight sideways first,

then inward. The best technique for introducing each new

stave somewhat resembles a door hinging. Leave them so

both edges line up with the line drawn near the edge of

the tub. After this, on every second stave for 4’ and 5’

tubs and on every third stave for 6’ - 8’ tubs, do your best

to put in a very small gap of about 1/32”. Make the others

tight against each other as best you can. This is an

important step so take your time. Use the mirror and your

tape measure to judge the gap.

There’s another helpful option you can consider using,

which is to use playing cards as shims. Slide them from

below between the staves and below the floor and place

them between every stave. If they still slide up and down

pretty easily with just very slight friction, this is pretty

close to the overall gapping you’re trying to achieve.

These will be removed after all staves are on and before

the stave tightening sequence is begun. NOTE: One card

between each stave may not be the perfect amount. When

you reach the end you will still have to assess and

possibly go back and space some staves a bit more (add 2

cards to some seams every so often) or a bit less (take

some cards out), depending on how it works out.

IMPORTANT: All presence or lack of gaps between

staves should be viewed and judged from the bottom

ends of the staves NOT the tops. The tops won’t come

into place until after retention band tightening. See

Figures 6.1.1 and 6.2

Continue in this fashion to work your way around the tub

adding staves.