GZ400

GB-10

Fine adjustment of the idling speed T

Adjust the idle speed with the T-screw. If it is necessary to

readjust, turn the T-screw clockwise while the engine is run-

ning, until the chain starts to rotate. Then turn counter-clock-

wise until the chain stops. A correctly adjusted idle speed set-

ting occurs when the engine runs smoothly in every position. It

should also be good margin to the rpm when the chain starts

to rotate.

Contact your servicing dealer, if the idle speed set-

ting cannot be adjusted so that the chain stops.

Do not use the chain saw until it has been properly

adjusted or repaired.

■ CHAIN BRAKE

This machine is equipped with an automatic brake to stop saw

chain rotation upon occurrence of kickback during saw cut-

ting. The brake is automatically operated by inertial force, which

acts on the weight fitted inside the front guard.

This brake can also be operated manually with the front guard

turned down to the guide bar.

To release the brake, pull up the front guard toward the front

handle till a “click” sound is heard.

[Caution]

Be sure to confirm brake operation during daily inspection.

How to confirm:

1) Turn off the engine.

2) Holding the chain saw horizontally, release your hand from

the front handle, hit the tip of the guide bar to a stump or a

piece of wood, and confirm brake operation. Operating

level varies by bar size.

In case the brake is not effective, ask our dealer for inspection

and repairs.

If the engine keeps rotating at high speed with the brake en-

gaged, the clutch will overheat causing trouble.

When the brake engages during operation, immediately re-

lease the throttle lever to stop the engine.

■ STOPPING THE ENGINE

1. Release the throttle lever to allow the engine to idle for a

few minutes.

2. Set the switch to the “O” (STOP) position.

[Important]

Do not put the chain saw on the ground when the chain is still moving.

For additional safety, set the chain brake when the saw is not in use.

In the event that the ignition switch will not stop the saw, pull

the choke knob out to the fully extended position "FULL

CHOKE" and engage chain brake to stop the engine. If the

ignition switch will not stop the saw when set to the "STOP"

position, have the ignition switch repaired before using the chain

saw again to prevent unsafe conditions or serious injury.

Note: When you are finished using the saw, always re lieve tank pressure

by loosening, then retightening, the chain oil and fuel mix caps. Allow

the engine to cool before storing.

Carburetor anti-freeze mechanism

Operating chain saws in temperatures of 0 – 5°C at times of high

humidity may result in ice forming within the carburetor, and this in

turn may cause the output power of the engine to be reduced or for

the engine to fail to operate smoothly.

This product has accordingly been designed with a ventilation hatch on

the right side of the surface of the cylinder cover to allow warm air to be

supplied to the engine and to thereby prevent icing from occurring.

Under normal circumstances the product should be used in the nor-

mal operating mode, i.e., in the mode to which it is set at the time of

shipment. However when the possibility exists that icing may occur,

the unit should be set to operate in the anti-freeze mode before use.

Continuing to use the product in the anti-freeze

mode even when temperatures have risen and re-

turned to normal, may result in the engine failing to

start properly or in the engine failing to operate at

its normal speed, and for this reason you should

always be sure to return the unit to the normal oper-

ating mode if there is no danger of icing occurring.

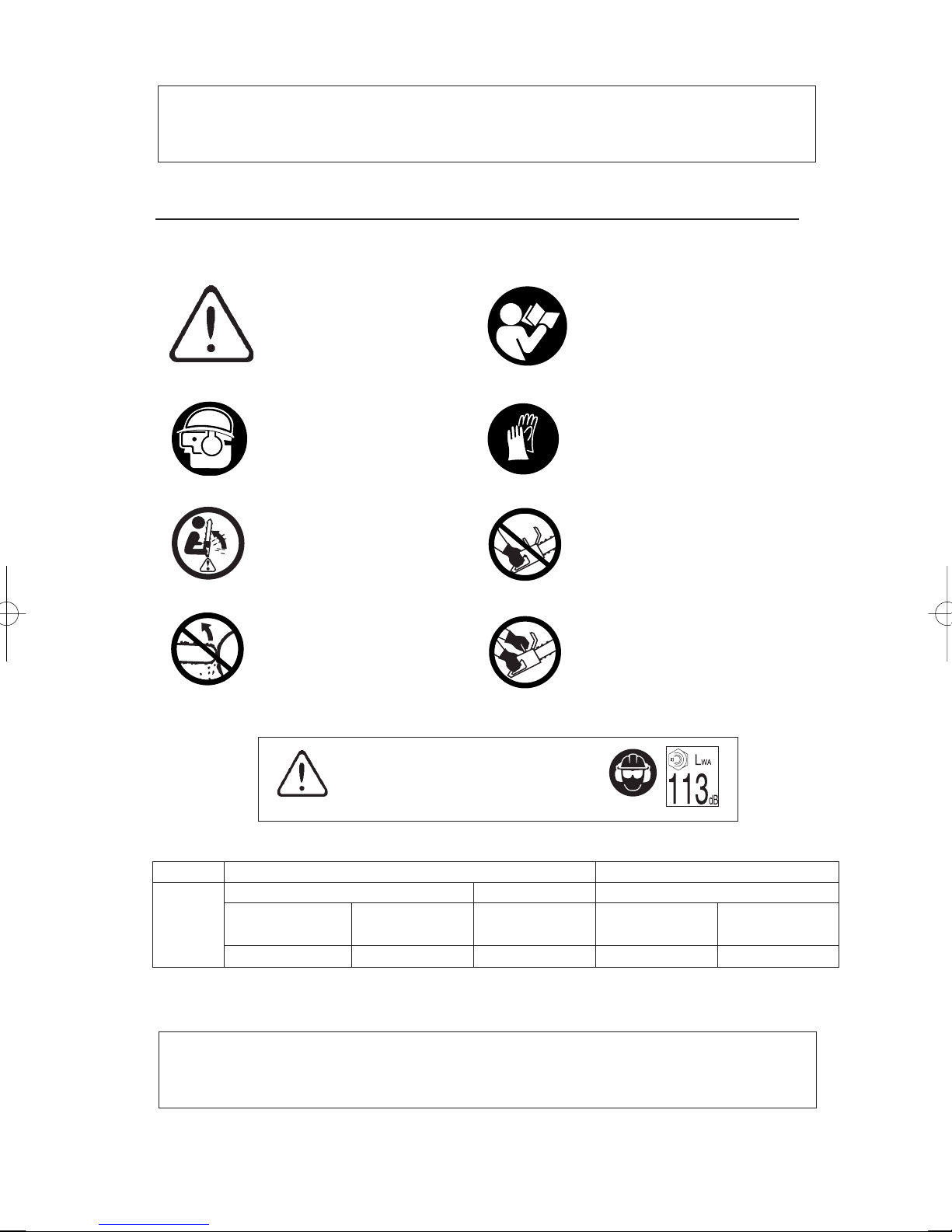

■ HOW TO SWITCH BETWEEN OPERATING MODES

1. Flip the engine switch to turn off the engine.

2. Remove the cover to the air filter, remove the air filter, and

then remove the choke knob from the cylinder cover.

3. Loosen the screws holding the cylinder cover in place (i.e.,

the three screws on the inside and the one screw on the

outside of the cover), and then remove the cylinder cover.

4.

Press with your finger down on the icing cap located on the

right-hand side of the cylinder cover to remove the icing cap.

5.

Adjust the icing cap so that the “snow” mark faces upwards

and then return it to its original position in the cylinder cover.

6. Fix the cylinder cover back into its original position, and

then fix all other parts back into their proper positions.

Switch

Choke knob

Cylinder cover

Icing cap

T-screw

Normal operating mode Anti-freeze mode

Cylinder cover

“Sunshine” mark “Snow” mark