After Each Use:

1. Clean the dome top, intake filter screen, gasket and

recovery tank with fresh, clean water. Do not reinstall

the dome until the next use, this will allow the recovery

tank to dry out.

2. Flush the solution tank and inlet screen with clean

water. Vacuum all water out using the Power Fill adap-

tor.

3. Remove any debris on the scrub brush, vacuum head

and around the spray jets.

5. Make sure the brush assembly lift lever is locked in the

raised position.

6. Store your machine in a dry, protected area. Do not

expose this machine to rain, standing water or freez-

ing temperatures.

Periodically:

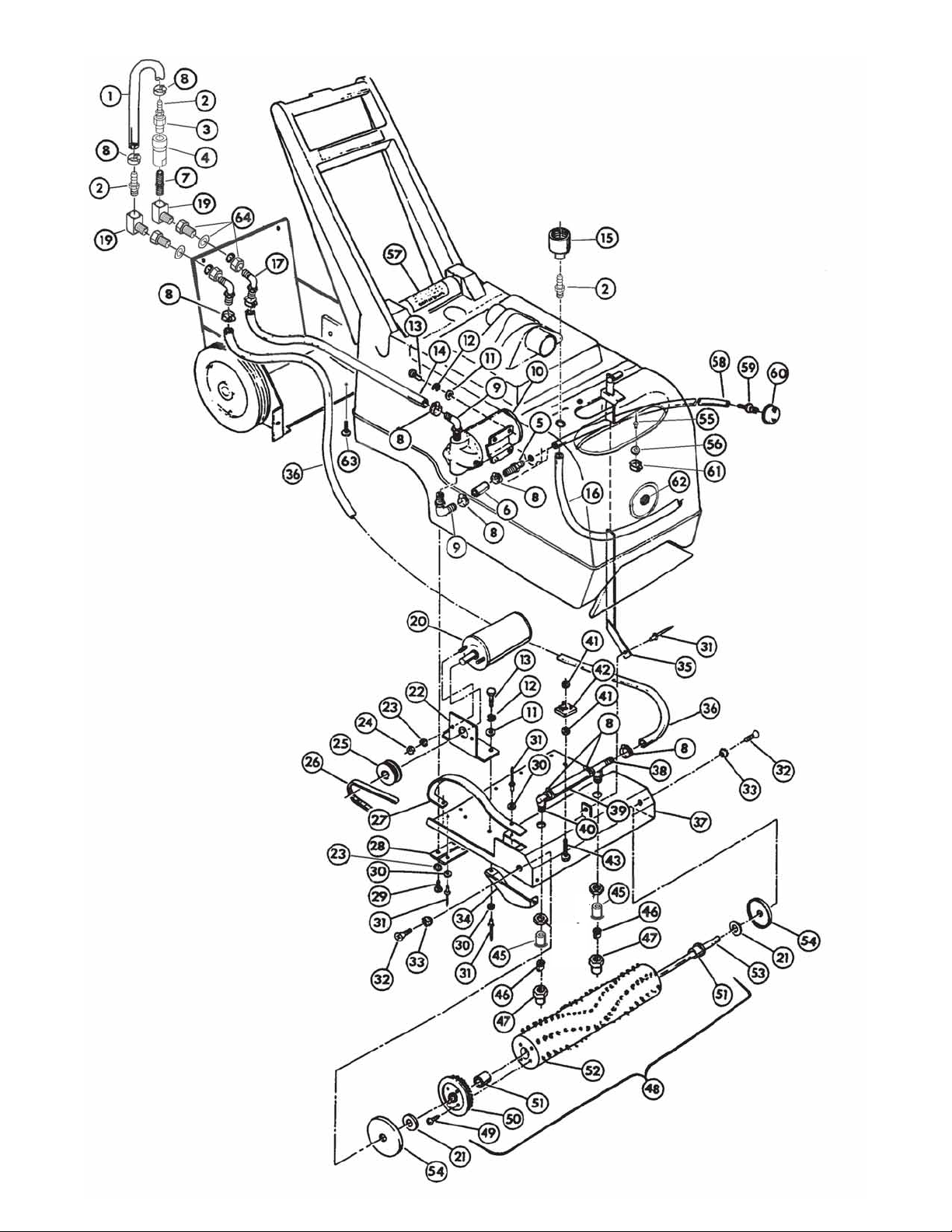

Aftercontinuous or repeateduse the jets and check valves

will need cleaning: Unplug the cord and empty the recov-

ery and solution tanks. Tilt the machine backward. Re-

move the jet caps, jets and check valves shown in the brush

assembly illustration and soak in white vinegar until visible

deposits are dissolved, then scrub with a soft bristle brush.

Note: jets and check valves should be replaced once a

year, because they tend to erode under extended use. This

may cause overuse of solution and streaking.

8. Release the red button approximately 6 inches be-

fore completing each pass. The spray jets are lo-

cated behind the vacuum head making it necessary to

pull the machine a few inches further to pick up the last

amount of solution dispensed onto the carpet.

9. Tilt the machine back on the rear wheels and walk

forward to position the machine along side the previ-

ous pass (slightly overlapping).

10. As dirty solution is recovered, some foaming may be

noted. Excessive foaming can be counteracted with

liquid defoamer applied according to the chemical

manufacturing directions. Do not allow foam to rise

into or near the dome; this will harm the vacuum

motor. Use defoamer or empty and flush the recovery

tank.

11. To empty the recovery tank, remove the dome as-

sembly and lift the tank out. Dispose of the recovered

water properly.

12. If streaking occurs after a period of operating time,

thismeans the solution (freshwater) tankisnear empty.

Streaking is eliminated by adding more water and

chemical solution to the tank. Empty the recovery

tank every time you fill the solution tank.

13. Toempty the solutiontankconnectthePowerFilladap-

tor to the vacuum inlet on the front of the dome. Turn

the vacuum switch on.

5

The Zep 430 self-contained extractor is designed and

manufactured to provided years of trouble free service with

a minimum of maintenance and service. The following

recommendations are intended to assist the operator and

Service Technician in performing routine maintenance.

WARNING: Always unplug your machine before perform-

inganyservice. Severepersonalinjurycouldresult if the

electrical power is not disconnected.

OPERATING WITH ACCESSORY TOOLS

1. To use an accessory tool disconnect the supply hose

at the rear of the machine and connect the accessory

tool hose .

2. Next, disconnect the machine’s vacuum hose from

the front of the dome assembly and connect the ac-

cessory tool vacuum hose to the dome.

3. Turn the vacuum and accessory pump switches on.

Solution will be dispensed while the accessory tool

trigger is depressed.

Watch the dome to make sure the recovery tank does

not overflow.

Note: The pump motor is equipped with an automatic ther-

mal protection device. If the motor overheats for any rea-

son, the thermal protector will activate and automatically

turn the motor off. If this occurs the operator should turn the

manual pump switch to the off position and allow approxi-

mately fifteen minutes for the motor to cool. When the

motor has cooled to a safe operating temperature, the ther-

mal protector will automatically close and allow power to

be supplied to the motor via the manual pump switch. The

operator will be able to resume normal operation. If the

pump motor shuts down repeatedly, it should be checked

at anAuthorized Service Center.

SERVICING

OPERATINGPROCEDURES