1

1

2

2

3

3

4

4

5

5

6

6

A

B

C

D

Denna ritning är Z-Lyftens egendom och skyddad enligt internationellt gällande lag för copyright

och får ej utan Z-Lyftens skriftliga medgivande kopieras, delges eller obehörigen användas.

This drawing is property of Z-Lyften Produktion AB and is loaned subject to return upon demand. It is not

to be reproduced or used directly or indirectly in any way detrimental to the interest of Z-Lyften Produktion AB.

Drawing interpretation unless otherwise

specified.

All measures intends finished product

Title

Material

Dimension

Date

Weigh(kg)

Scale

Designer Checked by Approved by

Stock nr.

Drawing nr.

Sheet

Size

Revision

IS0 tolerances and drawing rules

Tolerance:

Surface finish:

Welding:

1

/

1

Drawn

A CARGOTEC BRAND

Used on:

ZEPRO

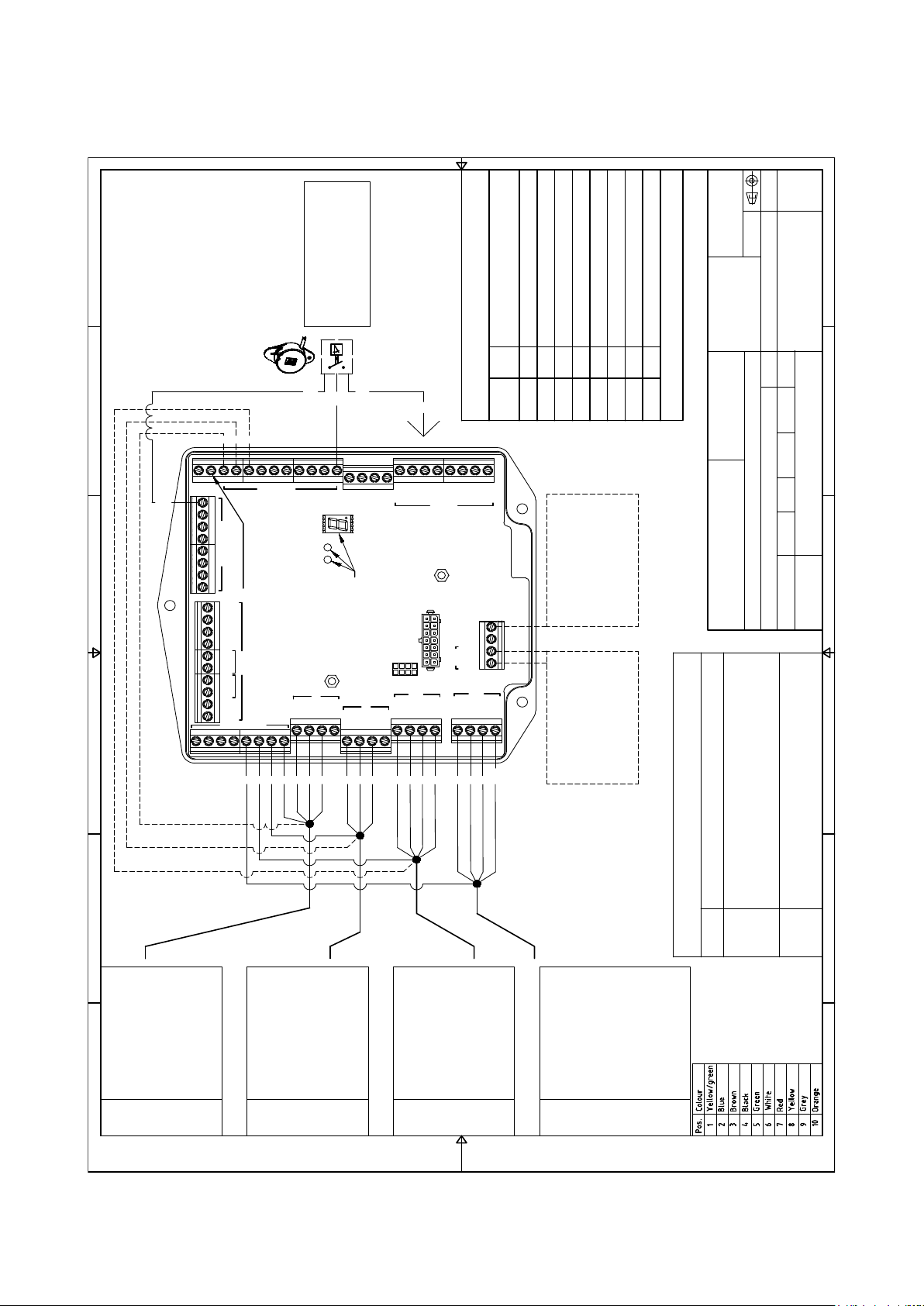

El & hydraulschema

E&H Schematic

Lyftar med 2H vinkelgivare

Lifts with 2H anglesensor

Z53534

75530TL

2016-07-04 MB MB PS PS

A2

-

--

1:1

Z-Lyften Produktion AB

-

-

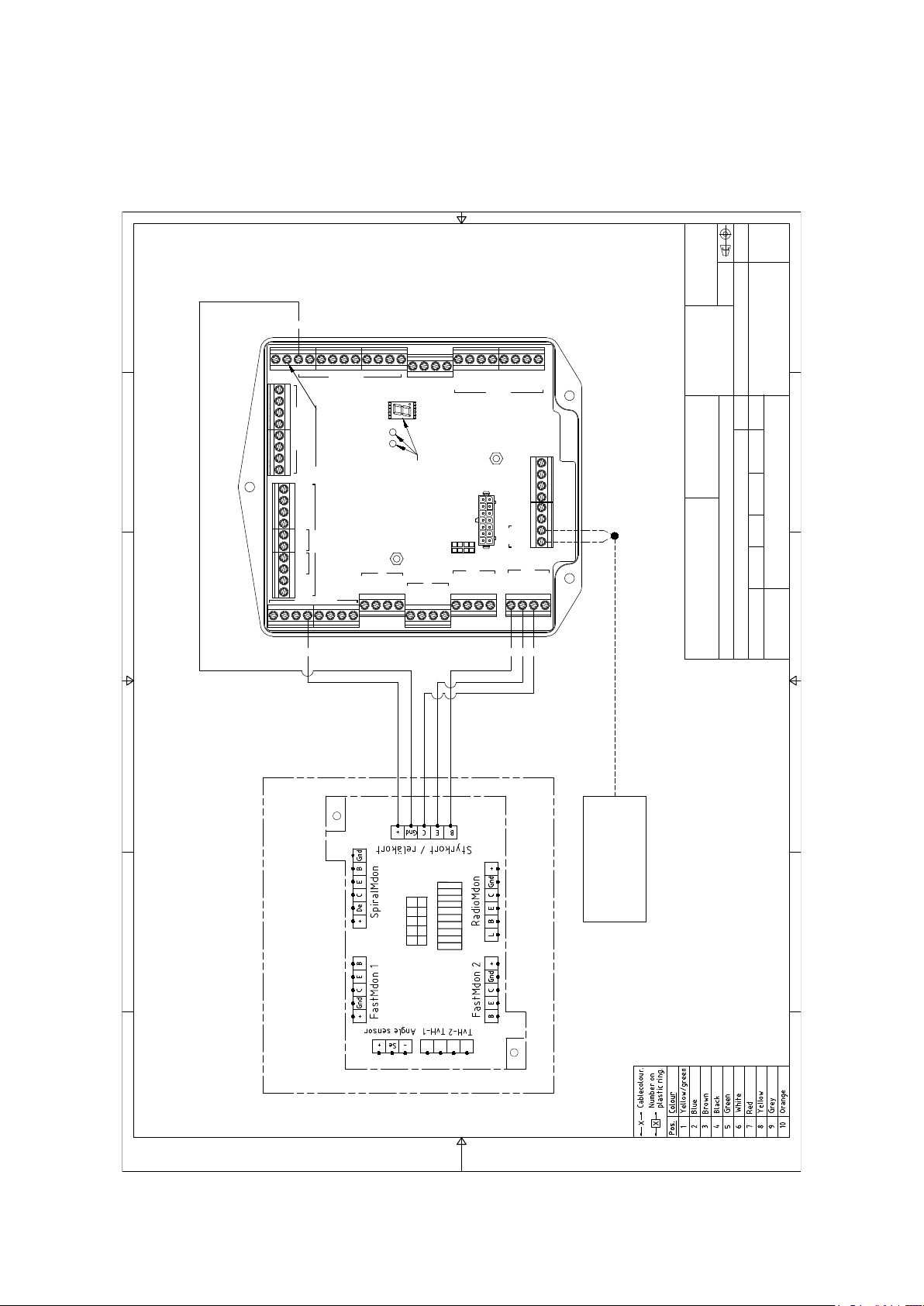

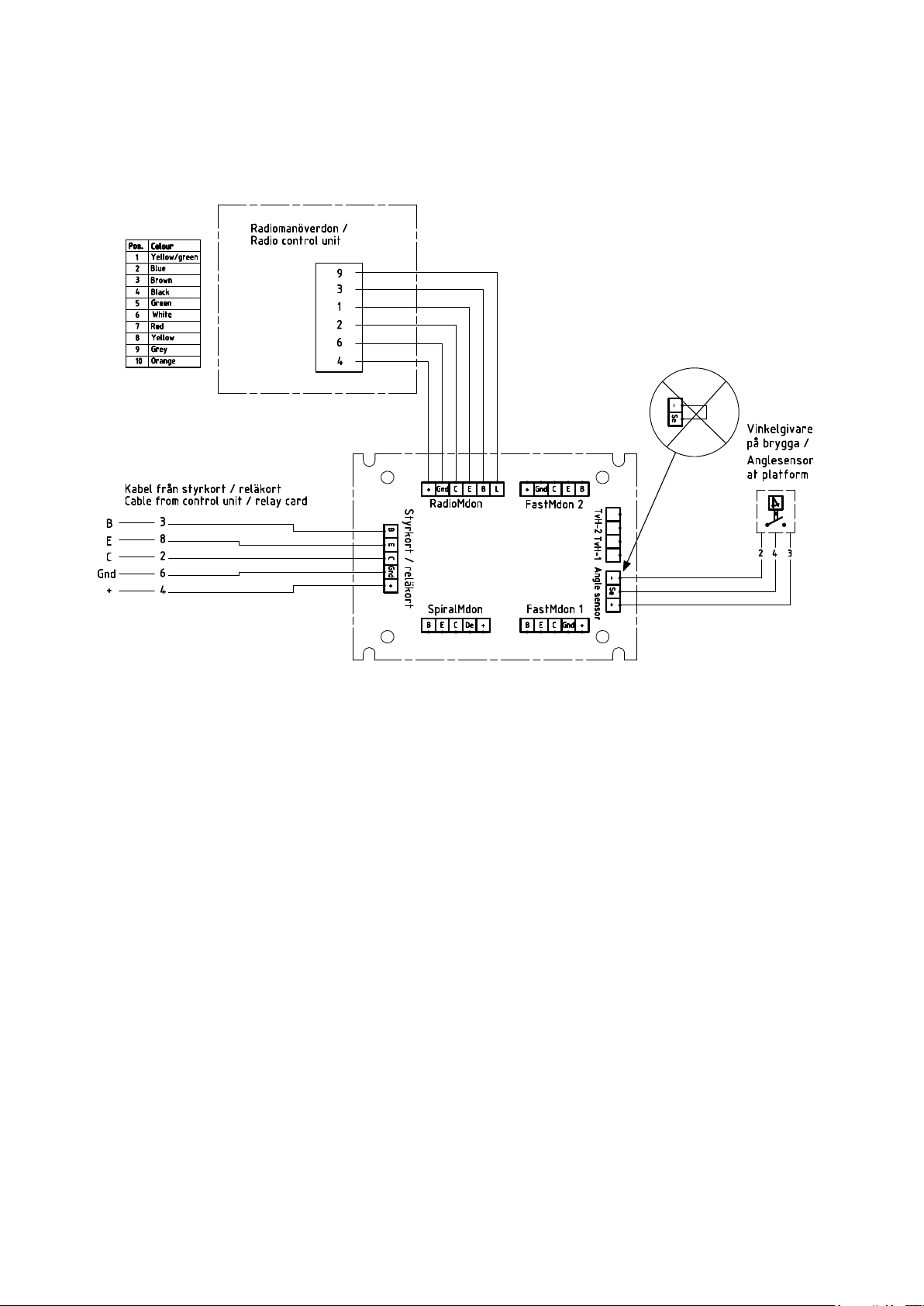

Ctrl 4

Spiral

Ctrl 3

Radio

Ctrl 2

Ctrl 1

Control Power

Sensor Power

Ground

IN OUT

Ai 1

Ai 2

Di 1

Di 2

Di 3

Di 4

Di 5

Di 6

PA-

PA+

CSPWR

CS

+

B

E

C

2H1

B

E

C

2H2

B

E

C

Lock

B

E

C

Lock

U7

U6

U5

U4

U3

U5

U4

U2

U1

U0

Ctrl 6

Out

In

GND/Spk-

LLED/Spk+

I-

I+

CR

CT

Ctrl 5

Indication

Se appendix in

installation manual

Outputs

Sensors

Not in use

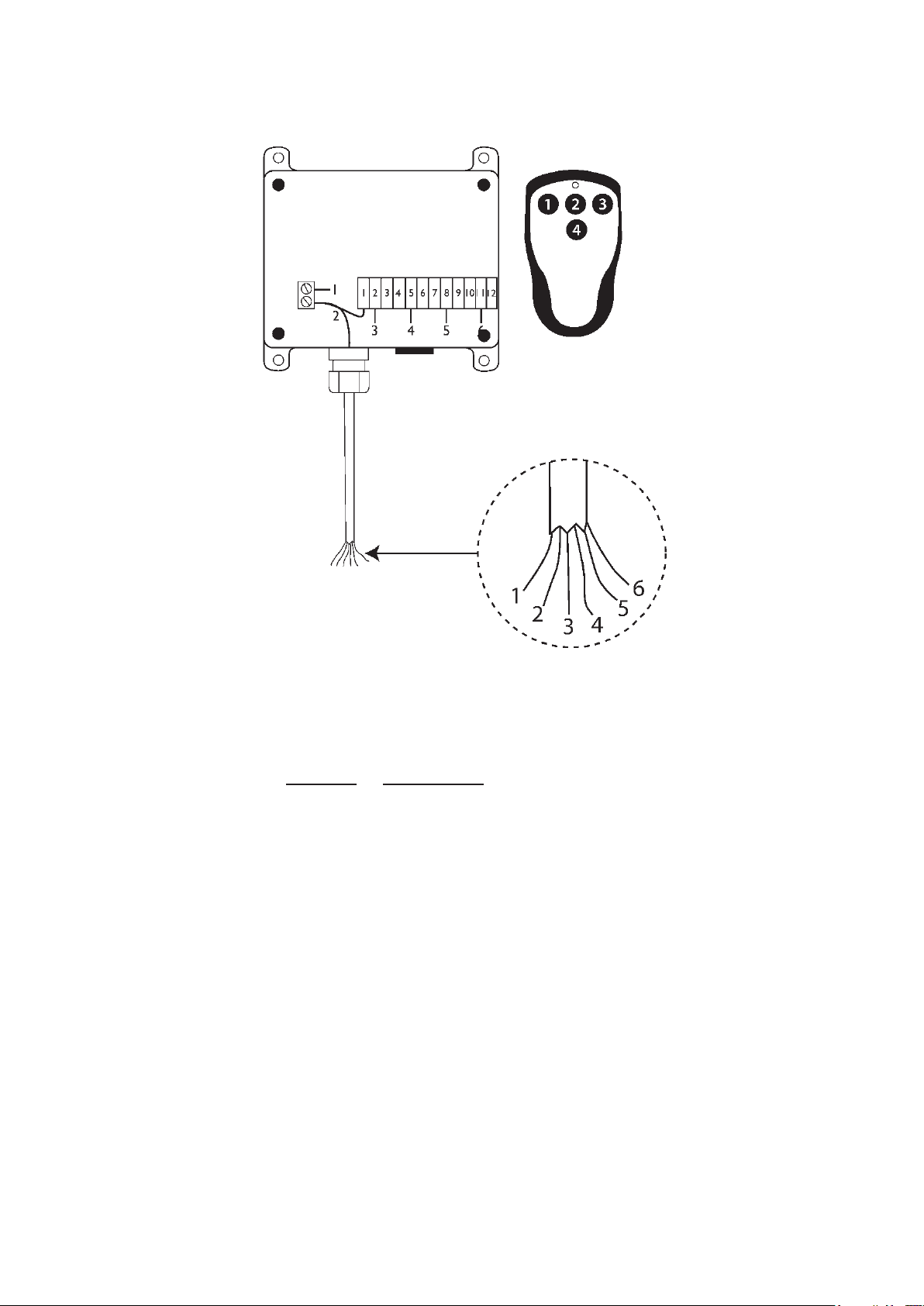

2-3 Knappsdon

---

2-3 Button Control

10

2

8

3

2

8

3

2

8

3

4

4

4

6

6

3

Ctrl 1Ctrl 2

2-3 Knappsdon

---

2-3 Button Control

Slädmanöverdons

anslutning*

---

Sledcontroller

connection*

Ctrl 4

Spiralmanöverdon

---

Spiral cable controller

Anslutningstabell / Connectiontable

Config Input Exempel på lyftmodeller (inte alla) /

Examples of liftmodels (not all)

1 Di2 ZHD,Z45,Z75,ZAHD,ZKZ,ZS,ZD,ZT

2-Se anteckningar / See notes***

3 - Se anteckningar / See notes***

6 Di3 SZHS

8 Di6 Z100

9 Di3 Z3N

12 -Se anteckningar / See notes***

13 Di3 ZHDN

- Ingen vinkelgivare / No anglesensor

Se anslutningstabell nedan var

vinkelgivare ska monteras /

See connectiontable below

where to connect anglesensor

Jord anslutning finns ej på alla manöverdon / Earth connection is not present on all controls

4

Manöverdon

låsindikering**

---

Controller lock

indication**

Information

*

Beror på typ av lyft / Depends on the type of lift.

**

Anslutning av LED jord för manöverdon på CTRL1, 2

med låsindikering (ej spiral) / Connection for LED earth

used for controls connected to CTRL1,2 with LED

indicating lock (not spiral)

***

Vissa ZHD varianter främst som byggs med ett annat

arbetssätt på hydraulik / Certain ZHD variants that are

built on a different type of hydraulic design

2

Ctrl 3

Radiomanöverdon

---

Radiocontrol

3

4

2

8

3

9

46

5. Electric- and hydraulic diagram