Nibco LD-7000 Series Guide

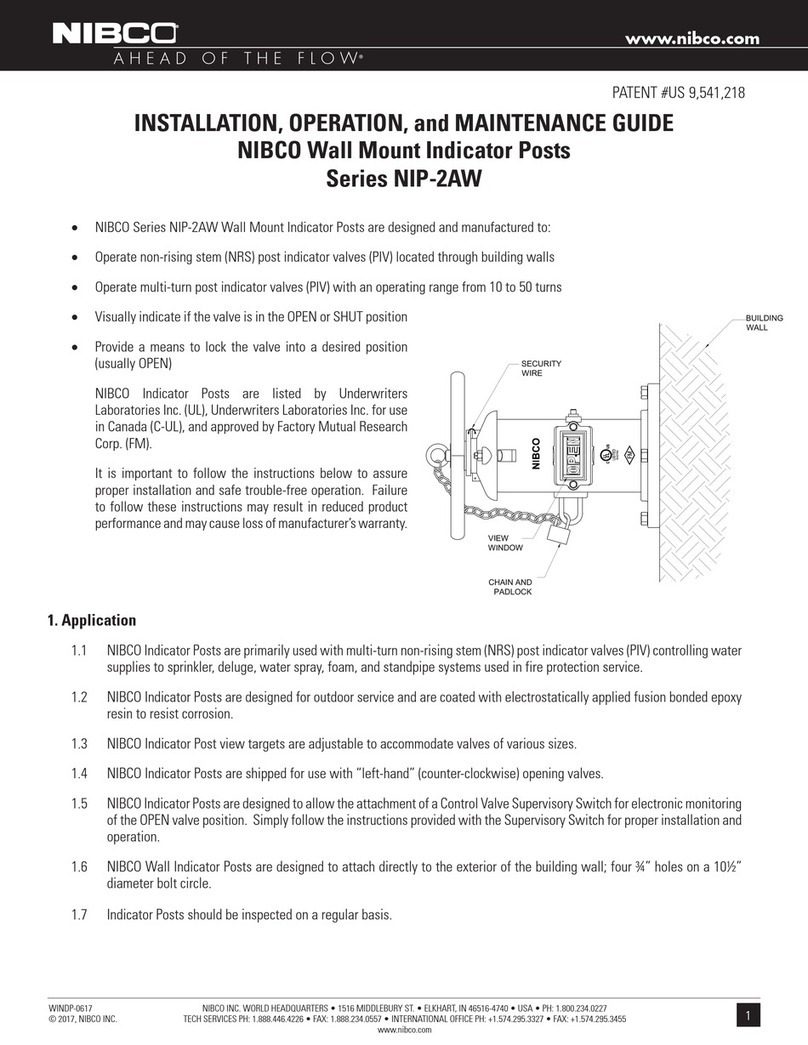

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

CAUTION: Only qualified personnel should undertake the procedures outlined in this document. NIBCO

INC., its agents, representatives and employees assumes no liability for the use of these procedures. These

procedures are offered as suggestions only.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

1

NIBCO INC.

WORLD HEADQUARTERS

1516 MIDDLEBURY ST.

ELKHART, IN 46516-4740

USA

PHONE: 574.295.3000

FAX: 574.295.3307

WEB: www.nibco.com

Review Date: NA

Original Date: 3/23/2022

USA ONLY

Installation and Maintenance Guidelines for

NIBCO®Flanged Butterfly Valves with Rubber Seats

Figure Numbers

LD-7000 Series

LD-3000 Series

Pressure Rating

232 psi / 16 Bar CWP - LD-7000 Series

250 psi / 17.2 Bar CWP – LD-3000 Series

Valve Size Range

14” – 48” - LD-7000 Series

(DN 350 - DN 1200)

14” – 24” - LD-3000 Series

(DN 350 - DN 600)

For any technical inquiries please call NIBCO Technical Services

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

2

I. SHIPMENT & STORAGE

NIBCO butterfly valves are packaged depending on valve size and quantity shipped. Smaller size

butterfly valves are bulk crated, larger size butterfly valves are crated individually. The butterfly

valve faces are covered with hardboard or plywood to protect flange sealing surfaces.

The disc is shipped in the nearly closed position to protect the sealing edge and prevent the liner

from taking a temporary set. The stem bushings and disc edge have been coated with a factory-

applied lubricant to prolong storage and service life.

Valves may be shipped or stored in any position. Storage should be limited to 10 years indoors with

a temperature range of 40º F to 90º F (4°C to 32°C).

II. BUTTERFLY VALVE INSTALLATION GUIDELINES

Review valve pressure rating on nameplate and system pressure limits to ensure valve is rated for

the intended service. Do not exceed the pressure rating of the valve.

NIBCO rubber-lined butterfly valves, depending on size and pressure rating, are designed to mate

with Class 125/150 flange patterns in conformance to ASME B16.1, ASME B16.5, or ASME B16.47

Class 150 (Series A) flanges. Cast iron and steel flat-face flanges can be used with all NIBCO

butterfly valves.

While flange standards specify flange OD, thickness, bolt size, bolt-circle diameter, and number of

bolts, they may not specify flange opening ID. Care must be used when selecting mating

components for use with NIBCO flange style butterfly valves. The internal diameter of flanges,

fittings, and pipe must be compatible with the butterfly valve for proper seal-face integrity

and disc operation.

When in the open position, the disc extends outward from the valve body. The internal diameter of

connecting components must be large enough to allow clearance for the disc to fully open. The

disc clearances specified in TABLE 1 (below) are in accordance with MSS Standard Practice SP-

67 Butterfly Valves, Table A1.

NIBCO 14” thru 48” size butterfly valves have an integral rubber face that seals to the attaching

flange; therefore, a separate gasket is not necessary and should never be used.

The flange inside diameter must not be too large or it will not mate properly with this integral seal.

See TABLE 1 (below) for minimum and maximum inside diameters of connecting piping/flanges to

assure proper seal-face integrity and full operation of NIBCO butterfly valves. Verify the inside

diameter and clearance dimensions of all components connecting directly to a butterfly valve.

VALVE

SIZE

MINIMUMPIPE

/FLANGEIDFOR

DISCCLEARANCE

MAXIMUMPIPE

/FLANGEIDFOR

PROPERSEAL

VALVE

SIZE

MINIMUMPIPE

/FLANGEIDFOR

DISCCLEARANCE

MAXIMUMPIPE

/FLANGEIDFOR

PROPERSEAL

14"12.88”15.50”30"29.08”31.28”

350mm327mm394mm750mm739mm795mm

16"15.06”17.90”36"33.60”36.77”

400mm383mm455mm900mm853mm934mm

18"17.02”19.67”42"39.87”44.96”

450mm432mm500mm1050mm1013mm1142mm

20"18.96”21.05”48"44.86”21.57”

500mm482mm535mm1200mm1139mm548mm

24"23.04”25.57”

600mm585mm649mm

TABLE 1

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

3

VALVE INSTALLATION GUIDELINES CONTINUED

Butterfly valves should be installed a minimum of six (6) pipe diameters from other line components

and changes in direction in both the upstream and downstream piping. This assures disc clearance

when opening the valve and reduces internal stress on disc by reducing flow turbulence. While not

always practical, it is important to design in as much straight distance on either side of the butterfly

valve as possible.

NIBCO butterfly valves are bi-directional and may be installed with flow in either direction. These

valves can be installed in any horizontal or vertical position. If a choice of stem positions exists, the

valve should be installed with the stem in the horizontal position; this will minimize seat wear by

distributing the stem and disc weight evenly. Also, if the media is abrasive, the horizontal stem

position is highly preferred, which will allow the disc to act as a “scoop” to sweep the line of the

media when operated.

When using a valve with gear operator attached, it may be desirable to have the hand wheel

positioned to allow easy access, or for use of an optional sprocket rim (chain wheel) for remote

operation. It is the responsibility of the installer to determine if a Retaining Harness is needed when

using a chain wheel. Before valve installation, review how to orient the gear operator hand wheel

position in relation to the valve body and piping system. Pre-planning may save from having to

remove a newly installed valve and reinstalling in another orientation.

Open and close the butterfly valve fully before attempting to install it into a piping system to ensure

the gear operator stops are properly set and the valve is fully functional. If the gear operator is

removed from the valve for any reason, prior to or during installation, the gear operator stops must

be properly reset as per Section IV, on page 5.

III. VALVE INSTALLATION PROCEDURE

Always position the connecting pipe flanges accurately in the line, allowing sufficient space between

the flanges for the valve. Make sure the pipe flange faces are clean of any foreign material such as

scale, metal shavings or welding slag. Valves should be installed with the disc in the closed position

to prevent damage to sealing surfaces. Rubber seated butterfly valves have an integral rubber face

that seals to the attaching flanges, therefore separate gaskets should not be used.

1. Fully close valve and inspect to assure disc is centered equally in the seat. Adjust gear operator

CLOSE stop if necessary, to center disc in seat. See Section IV on page 5.

2. Carefully insert the valve between the pipe flanges. Do not apply any lubricants to the seat faces

as this may damage them.

3. Line up, center & secure the valve between flanges using customer supplied desired bolts as

listed in TABLE 2 on next page. Do not tighten bolts at this time, hand tighten then “snug-up”.

4. Carefully open the valve to assure free unobstructed disc movement. Disc interference may

result when valves are installed in pipelines having smaller than normal inside diameters, such

as heavy wall pipe, plastic-lined pipe, as-cast flanges, or reducing flanges. Interference can also

occur when connecting directly to a swing check or silent check. Suitable corrective measures

must be taken to remove these obstructions, such as taper boring the pipe or installing a spacer

or spool piece.

5. After proper operation is verified, tighten the bolts to the minimum recommended bolt torques

listed in TABLE 3, next page, using a cross-over pattern as shown in FIGURE 1, next page.

6. A multi-stepped process utilizing the cross-over pattern should be used to draw flanges against

the rubber seat from both sides of the valve at the same rate, ensuring even compression. This

should be followed by 2 sets of chase patterns, alternating from one side of the valve to the

other. Refer to ASME PCC-1 GUIDELINES FOR PRESSURE BOUNDRY BOLTED FLANGE

JOINT ASSEMBLY for bolt tightening methodology.

7. Pressurize piping to valve and inspect for leakage. If leakage is observed, tighten bolts using

cross-over pattern, increasing torque until leak stops.

DO NOT EXCEED MAXIMUM TORQUES LISTED IN TABLE 3 on next page.

8. Recommended torques are made without warranty. Installer must verify proper strength bolts

for application.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

4

VALVE INSTALLATION PROCEDURE - CONTINUED

RECOMMENDED BOLT LENGTHS

VALVESIZE

TOTALVALVEBODY

WIDTH

ASMEB16.1

CLASS125CASTIRON

FLANGETHICKNESS

ASMEB16.5

CLASS150STEEL

FLANGETHICKNESS

ASMEB16.47(SERIESA)

CLASS150STEEL

MSSSP‐44

FLANGETHICKNESS

RECOMMENDED

BOLTLENGTH

TOTALQUANTITY

CAPSCREWS/BOLTS

(TOMOUNTVALVE

BETWEEN2FLANGES

)

BOLT

THREADSIZE

14”3.011.381.38—2.5241‐8UNC

16”3.381.441.44—3321‐8UNC

18”4.121.561.56—3321‐1/8–7UNC

20”5.141.691.69—3.5401‐1/8–7UNC

24”5.981.881.88—4401‐1/4–7UNC

30”6.572.12——4.25561‐1/4–7UNC

——2.94556

36”8.002.38——5641‐1/2–6UNC

——3.56664

42”9.882.62——5.25721‐1/2–6UNC

——3.816.572

48”10.872.75——5.5881‐1/2–6UNC

——4.25788

TABLE 2

TABLE 3

BOLTGRADEBOLTHEAD

MARKING

LUBRICATEDBOLTSIZENON‐LUBRICATEDBOLTSIZE

1"‐81⅛"‐71¼"‐71½"‐61"‐81⅛"‐71¼"‐71½"‐6

ASTMA307ORTORQUE

FT./LBS.

MINIMUM457010017075100150240

SAEJ429GRADE2MAXIMUM140200300500240350500800

BOLT

TIGHTENING

SEQUENCE

⑩

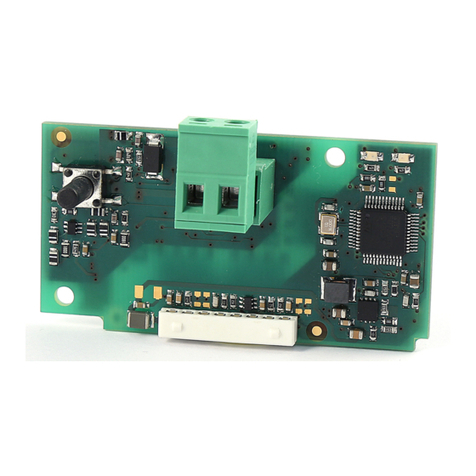

CIRCLED NUMBERS REPRESENTS BOLT NUMBER

16 BOXED NUMBERS REPRESENTS TIGHTEN SEQUENCE ORDER

FIGURE 1

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

5

IV. GEAR OPERATOR ADJUSTMENT

NOTE: It is best to visually check the valve disc OPEN and CLOSE positions before the valve is

installed in the system piping to assure proper valve operation.

1. Attach gear operator to the top of the valve and securely tighten bolts, or verify bolts are

securely tight if you received a valve with the gear operator already attached.

2. Fully close valve and inspect seat to assure disc is centered equally in seat. If not, CLOSE

stop adjustment is necessary.

IF VALVE DISC DOES NOT FULLY CLOSE

3. Loosen CLOSE stop nut on gear operator one turn by turning counterclockwise or remove

outer set screw. See FIGURE 2, 3, 4, & 5 on next pages.

4. Loosen CLOSE stop set screw 2 turns by turning counterclockwise.

5. Turn handwheel clockwise until valve disc is centered equally in seat.

6. Tighten CLOSE stop set screw by turning clockwise until it stops.

7. Tighten CLOSE stop nut until it is tight or reinstall outer set screw and tighten.

IF VALVE DISC TRAVELS PAST CLOSE POSITION

8. Turn handwheel counterclockwise until disc is centered in seat.

9. Loosen CLOSE stop nut on gear operator one turn by turning counterclockwise or remove

outer set screw.

10. Tighten CLOSE stop set screw, or inner set screw, by turning clockwise until it stops.

11. Tighten CLOSE stop nut until it is tight or install outer set screw and tighten.

12. If the valve is installed in the system piping and cannot be removed, it is possible to adjust

the stops, but is a little more difficult. The only difference is that instead of visually checking

the actual disc in the valve; you must visually check the pointer position. Because the exact

pointer position is more difficult to determine, it may take a couple tries to set the CLOSE

stop. OPEN stop adjustment is not critical; ±5° travel is adequate.

NOTE: The gear operator’s OPEN and CLOSE positions have been set at time of shipping.

These instructions should be used for slight adjustment as needed.

GEAR OPERATOR DIMENSIONS

VALVESIZEAABBCCDDEEFFGGHHJJPIN/KEYWEIGHT

14"4.723.942.132.36.9410.6310.2419.699.84.236”X2.17”58lbs.

350mm1201005460242702605002506X55mm26Kg.

16”,18”20"4.137.282.522.36.9414.9611.4211.819.84.236”X1.57”90lbs.

400,450,500mm1051856460243802903002506X40mm41Kg.

24”5.515.913.312.52.9414.2513.7819.6911.81.236”X2.17”145lbs.

600mm1401508464243623505003006X55mm66Kg.

30",36"6.376.953.464.051.109.747.6617.6813.91.315"X1.57"339lbs.

750,900mm16217788103282481954503548X40mm154Kg.

42",48"13.569.745.895.781.4116.279.3519.6528.45.315"X1.57"924lbs.

1050,1200mm345248150147364142385007248X40mm420Kg.

TABLE 4

See FIGURE 2, FIGURE 3, FIGURE 4, and FIGURE 5 on next pages for drawings

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

6

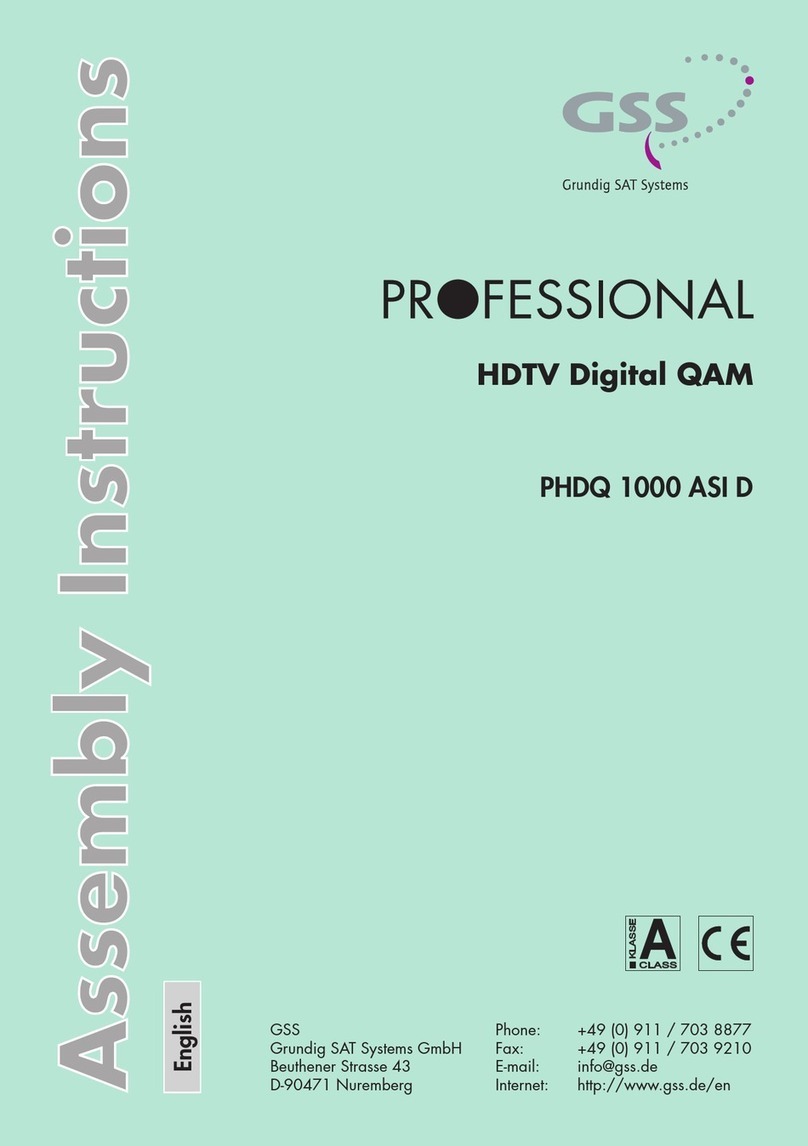

GEAR OPERATOR FOR 14” SIZE BUTTERFLY VALVES

FIGURE 2

GEAR OPERATOR FOR 16” THRU 24” SIZE BUTTERFLY VALVES

FIGURE 3

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

7

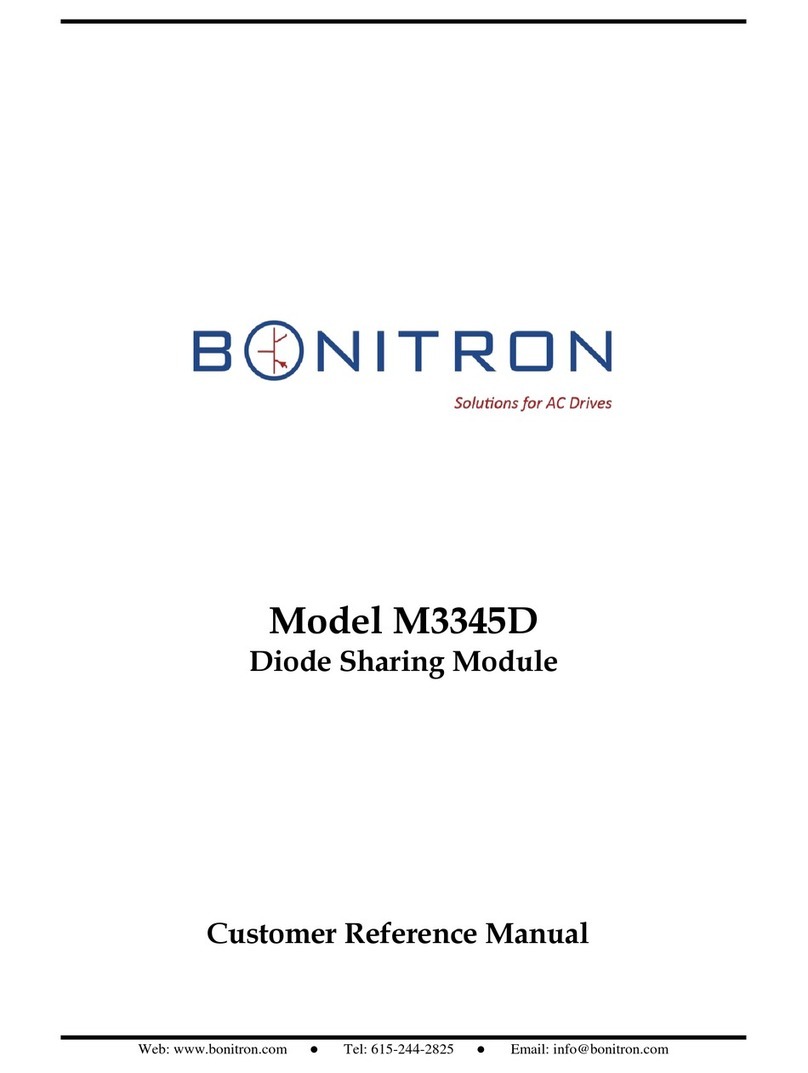

GEAR OPERATOR FOR 30” & 36” SIZE BUTTERFLY VALVES

FIGURE 4

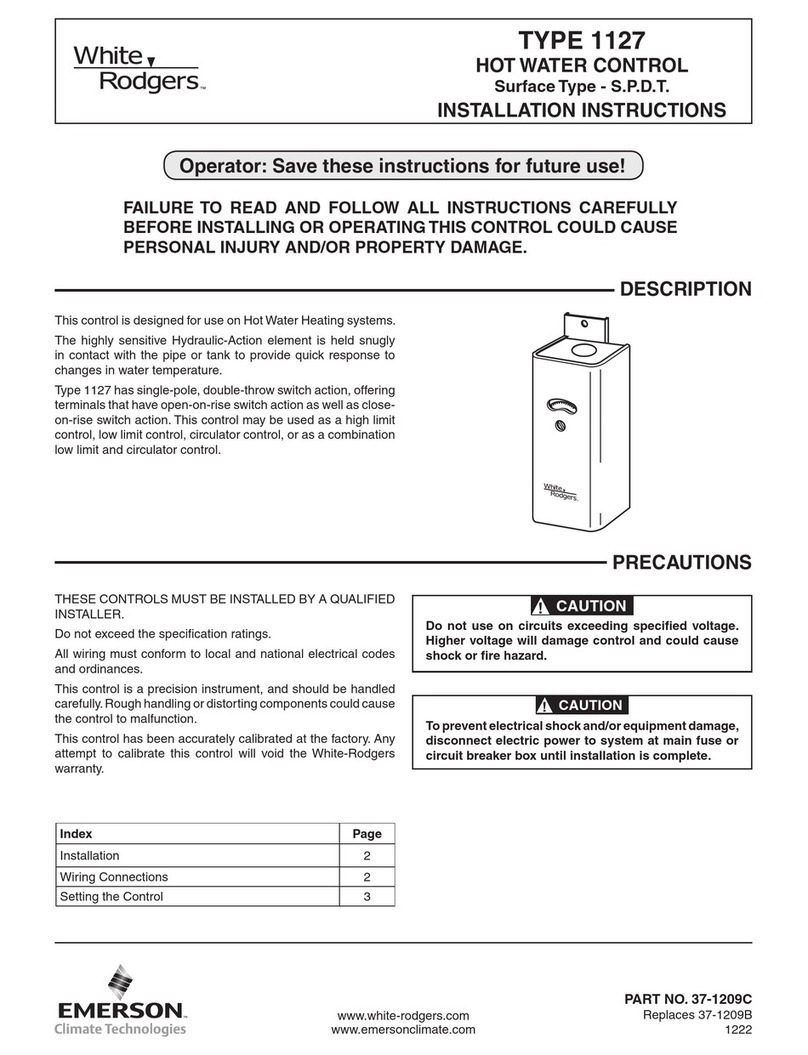

GEAR OPERATOR FOR 42” & 48” SIZE BUTTERFLY VALVES

FIGURE 5

OPEN STOP CLOSE STOP

OPEN STOP CLOSE STOP

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

8

V. VALVE CONSTRUCTION - 14” THRU 24” SIZE BUTTERFLY VALVES

VALVE

SIZEUNITSABCD

(KEY)EFGHIJK

14"INCHES1.6870.4721.81.487X.315X1.614.020.475.511.8115.6711.3016.50

350mmmm42.861245.8612X8X401021214046.0398287419

16"INCHES1.9930.6302.15.630X.394X2.755.510.717.762.9916.9713.7418.90

400mmmm50.621654.6216X10X701401819776.0431349480

18"INCHES2.1250.6302.28.630X.394X2.755.510.717.762.9917.8314.4520.67

450mmmm53.981657.9816X10X701401819776.0453367525

20"INCHES2.4940.7092.65.709X.433X3.155.510.717.763.3918.9015.9122.05

500mmmm63.351867.3518X11X801401819786.0480404560

24"INCHES2.7560.7872.93.784X.472X3.1510.000.7110.873.3922.1318.1526.57

600mmmm70.002074.5020X12X802541827686.0562461675

VALVE

SIZEUNITSLMNOPQR

QTY

U

THREADSTGEAR

MOUNTWEIGHT

14"INCHES13.153.623.9420.9818.7512.87

241"‐8UNC1.18

F10220lbs.

350mmmm334.092100533476.332730100Kg.

16"INCHES15.364.024.3323.5021.2515.08

321"‐8UNC1.26

F14288lbs.

400mmmm390.1102110597539.838332131Kg.

18"INCHES17.374.494.8025.0022.7517.01

321⅛"‐7UNC1.38

F14354lbs.

450mmmm441.1114122635577.943235161Kg.

20"INCHES19.375.005.3127.5225.0018.98

401⅛"‐7UNC1.57

F14471lbs.

500mmmm192.1127135699635.048240214Kg.

24"INCHES23.346.066.3832.0129.5023.03

401¼"‐7UNC1.77

F25929lbs.

600mmmm592.8154162813749.358545422Kg.

TABLE 5

FIGURE 6

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

9

14” THRU 24” SIZE BUTTERFLY VALVES

ITEMQTYDESCRIPTIONMATERIALSPECIFICATIONS

11ENDCAPCOVERDUCTILEIRONASTMA53665‐45‐12

22SCREWSTEEL

31O‐RINGNITRILEASTMD2000

42BUSHINGSHORTBRONZEASTMB584C83600

51O‐RINGNITRILEASTMD2000

61STEMSTAINLESSSTEELASTMA276S42000

STAINLESSSTEELASTMA564S63000

71DISC

DUCTILEIRONA53665‐45‐12NYLON11COATED

ALUMBRZASTMA148C95400

STAINLESSSTEELCF8M

82TAPERPINSTAINLESSSTEELASTMA276S42000

STAINLESSSTEELASTMA564S63000

91SEATEPDMASTMD2000

NITRILEASTMD2000

102BUSHINGLONGBRONZEASTMB584C83600

111BODYDUCTILEIRONASTMA53665‐45‐12

122STUDSTEEL

132NUTSTEEL

141PACKINGRINGBRONZEASTMB584C83600

152V‐CUPPACKINGNITRILEASTMD2000

161UPPERPACKINGNITRILEASTMD2000

171PACKINGGLANDDUCTILEIRONASTMA53665‐45‐12

181KEYSTEEL

191RETAINERPLATESTEEL

202SCREWSTEEL

TABLE 6

FIGURE 7

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

10

30” THRU 48” SIZE BUTTERFLY VALVES

TABLE 7

VALVE

SIZEUNITSABCD

(2KEYS)EFGHIJK

30"INCHES2.9530.7873.31.787X.472X2.5011.730.8713.782.6033.3124.3332.28

750mmmm75208420X12X632982235066846618820

36”INCHES3.5430.9843.94.984X.551X4.0011.730.8713.784.6536.6729.2538.27

900mmmm902510025X14X10029822350118906743972

42INCHES4.1341.1024.611.102X.630X5.5014.021.3016.345.9141.1034.0246.46

1050mmmm1052811728X16X1403563341515010448641180

48"INCHES4.7241.2605.281.260X.709X5.5014.021.3016.345.9144.3737.4453.07

1200mmmm1203213432X18X143563341515011279511348

VALVE

SIZEUNITSLMNOPQR

QTY

S

THREADSTGEAR

MOUNTWEIGHT

30"INCHES29.336.577.0938.7436.0029.09561¼"‐7UNC2.13F301109lbs.

750mmmm745167180984914.473954504Kg.

36"INCHES34.067.998.3145.9842.7533.62641½"‐6UNC2.40F301762lbs.

900mmmm86520321111681085.985461801Kg.

42INCHES40.599.8810.2852.9949.5039.88721½"‐6UNC2.60F352746lbs.

1050mmmm103125126113461257.31013661248Kg.

48"INCHES45.6710.8711.2659.4956.0044.84881½"‐6UNC2.76F353498lbs.

1200mmmm116027628615111422.41139701590Kg.

FIGURE 8

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

11

30” THRU 48” SIZE BUTTERFLY VALVES

FIGURE 9

ITEMQTYDESCRIPTIONMATERIALSPECIFICATIONS ITEMQTYDESCRIPTIONMATERIALSPECIFICATIONS

11SCREWSTEEL 181DISCALUMBRZASTMA148C95400

21NUTSTEEL STAINLESSSTLCF8M

31WASHERSTEEL 191SEATEPDMASTMD2000

41O‐RINGNITRILEASTMD2000 NITRILEASTMD2000

54SCREWSTEEL 201BUSHINGLONGBRONZEASTMB584C83600

64WASHERSPRINGSTEEL 211BODYDUCTILEIRONA53665‐45‐12

71ENDCAPCOVERDUCTILEIRONA53665‐45‐12 221I.D.PLATEALUMINIM

81O‐RINGNITRILEASTMD2000 232RIVITALUMINIM

91ROLLPINSTEEL 242KEYSTEEL

102SPACERSTEEL 258SCREWSTEEL

111THRUSTBEARINGSTEEL 268WASHERSPRINGSTEEL

124BUSHINGSHORTBRONZEASTMB584C83600 278NUTSTEEL

132O‐RINGNITRILEASTMD2000 281TOPCONNECTIONSPTDUCTILEIRONA53665‐45‐12

141STEMLOWERSTAINLESSSTASTMA276S42000 291PACKINGRINGBRONZEASTMB584C83600

STAINLESSSTASTMA564S63000 304V‐CUPPACKINGNITRILEASTMD2000

151BUSHINGMID.BRONZEASTMB584C83600 311UPPERPACKINGNITRILEASTMD2000

163TAPERPINSTAINLESSSTLASTMA276S42000 321PACKINGGLANDDUCTILEIRONA53665‐45‐12

STAINLESSSTASTMA564S63000 332STUDSTEEL

171STEMUPPERSTAINLESSSTLASTMA276S42000 342NUTSTEEL

STAINLESSSTASTMA564S63000351PINSTEEL

181DISCDIASTMA536NYLONCOAT.361RETAININGRINGSTEEL

TABLE 8

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

12

VI. OPERATION

Rotate the gear operator handwheel in the counter-clockwise direction to open the valve. Rotate

the handwheel in the clockwise direction to close the valve. Disc position can be determined by

looking at the pointer plate located on top of the gear operator. Note that the keys in the stem

also align with the sealing edges of the disc.

VII. REPAIR

No regular scheduled lubrication or maintenance is required except for regular exercising of the

valve. The valve needs to be fully cycled every 6 months, at a minimum, and inspected for

smooth operation and external leakage.

VIII. TROUBLESHOOTING

ISSUE POSSIBLE REASONS SOLUTIONS

LEAKAGE AT

VALVE SEAT

DISC IS NOT FULLY CLOSED

ADJUST GEAR OPERATOR OR

ACTUATOR CLOSE STOP - SEE

SECTION I

V

CONTAMINATION ADHERED TO

SEALING SURFACES OF SEAT CLEAN BOTH SEALING SEAT SURFACES

RUBBER SEAT HAS ERODED CHECK MEDIA TO SEE IF COMPATIBLE

WITH RUBBER SEAT MATERIAL

EXTERNAL

LEAKAGE AT

LOWER STEM

END CAP O-RING DAMAGED REPLACE O-RING

RETAINING COVER O-RING

DAMAGED REPLACE O-RING

ADJUSTING SCREW O-RING

DAMAGED REPLACE O-RING

EXTERNAL

LEAKAGE AT

UPPER STEM

STEM V-CUP PACKING WORN EVENLY TIGHTEN PACKING GLAND

NUTS - DO NOT OVERTIGHTEN!

STEM V-CUP PACKING

ASSEMBLY DAMAGED

REPLACE STEM V-CUP PACKING

ASSSEMBLY

LEAKAGE AT

FLANGE

CONNECTION

FLANGE BOLTS ARE NOT TIGHT

OR NOT TIGHTENED

PROPERLY

EVENLY TIGHTEN ALL FLANGE BOLTS

USING CROSS-OVER / CRISS-CROSS

PATTERN

VALVE CONNECTED TO

IMPROPER SIZE FLANGE

REVIEW FLANGE DIMENSIONS AND

COMPARE TO TABLE 1, INSTALL

PROPER SIZE FLANGE

SURFACES OF FLANGE ARE

CONTAMINATED INSPECT AND CLEAN FLANGES

SURFACES OF FLANGES ARE

DAMAGED INSPECT AND REPAIR FLANGE DAMAGE

This manual suits for next models

1

Table of contents

Other Nibco Control Unit manuals

Nibco

Nibco T-413-B Product manual

Nibco

Nibco NIP-2AW series Manual

Nibco

Nibco Webstone Pro-Connect ProPush Series User manual

Nibco

Nibco Webstone Series User manual

Nibco

Nibco LD2000 Series Assembly instructions

Nibco

Nibco T-103-HC Product manual

Nibco

Nibco LD-1000 Series Product manual

Nibco

Nibco Pressystem User manual