ELECTRIC VEHICLE MANAGEMENT SYSTEM V3 ZERO EMISSION VEHICLES AUSTRALIA

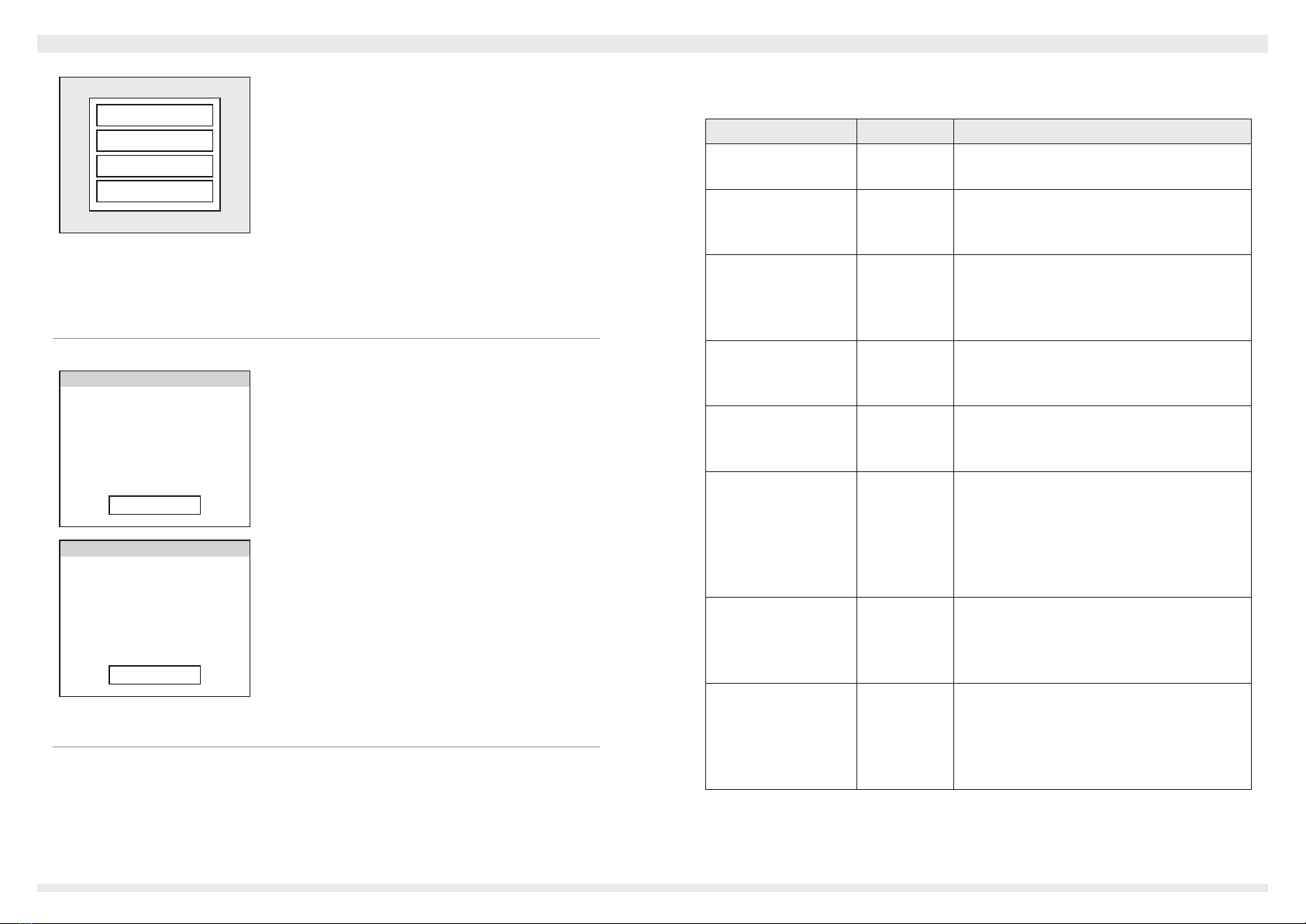

Current Sensor

TheEVMS3communicateswithacurrentsensorontheCANbustoreceiveinstantaneous

current,andusesthistocalculatebatteryStateofChargethroughintegrationovertime.Two

typesofcurrentsensorareavailable,HallEffectorShunt.

HallEffectcurrentsensorsareavailablefor300A,600Aor1200Amaximum,and•

areinstalledsimplybyslippingthebatterycablethroughthebluetorusofthehall

sensor.Smallerratedsensorsofferproportionallyhighermeasurementaccuracyso

aremoreappropriateforlowercurrentsystems.Hallsensorsarenormallyeasierto

installandgeneratenoheat,butarealittlemoreexpensiveandhaveslightlyless

accuratezeropoint.

TheShuntInterfacemeasurescurrentowthroughashuntinstalledonthebattery•

cableandoutputsittotheCANbus.TheShuntInterfacecanworkwith50A,100A,

200Aor500Ashunts,either75mVor50mV.Smallershuntsofferproportionately

highermeasurementresolution.Note that the current ratings for the shunts are

maximum continuous ratings, but the shunt interface can measure up to twice the

shunt’s nominal rating intermittently - limited by heat buildup in the shunt.Ashunt

interfaceplusshuntworksoutalittlecheaperthantheHallEffectsensorandhasa

slightlymoreaccuratezeropoint(betteraccuracywithverylowcurrents),butcan

bealittlemoreefforttoinstall,andgeneratessomeheat.

Asageneralguide,halleffectsensorsaremoresuitableforhighpowersystems,andshunts

aremoresuitableforlowerpowersystems.

Inbothcasesthecurrentsensororshuntmaybeinstalledoneitherthepositiveornegative

batterywire.TheHallSensorshouldbeorientedsuchthatdischargecurrentowsfromthe

back(black)sidetothefront(blue)side.Ensurethattherearenodevicesinstalledbetween

thebatteryandthecurrentsensororshunt,ortheEVMSwillnotbeabletocalculatestateof

chargecorrectly,sincethecurrentowto/fromthosedeviceswouldnotbemeasuredbythe

currentsensor.Note: If the status light is blinking when no current is owing, hold down the

button until it stops blinking to recalibrate the sensor’s zero point.

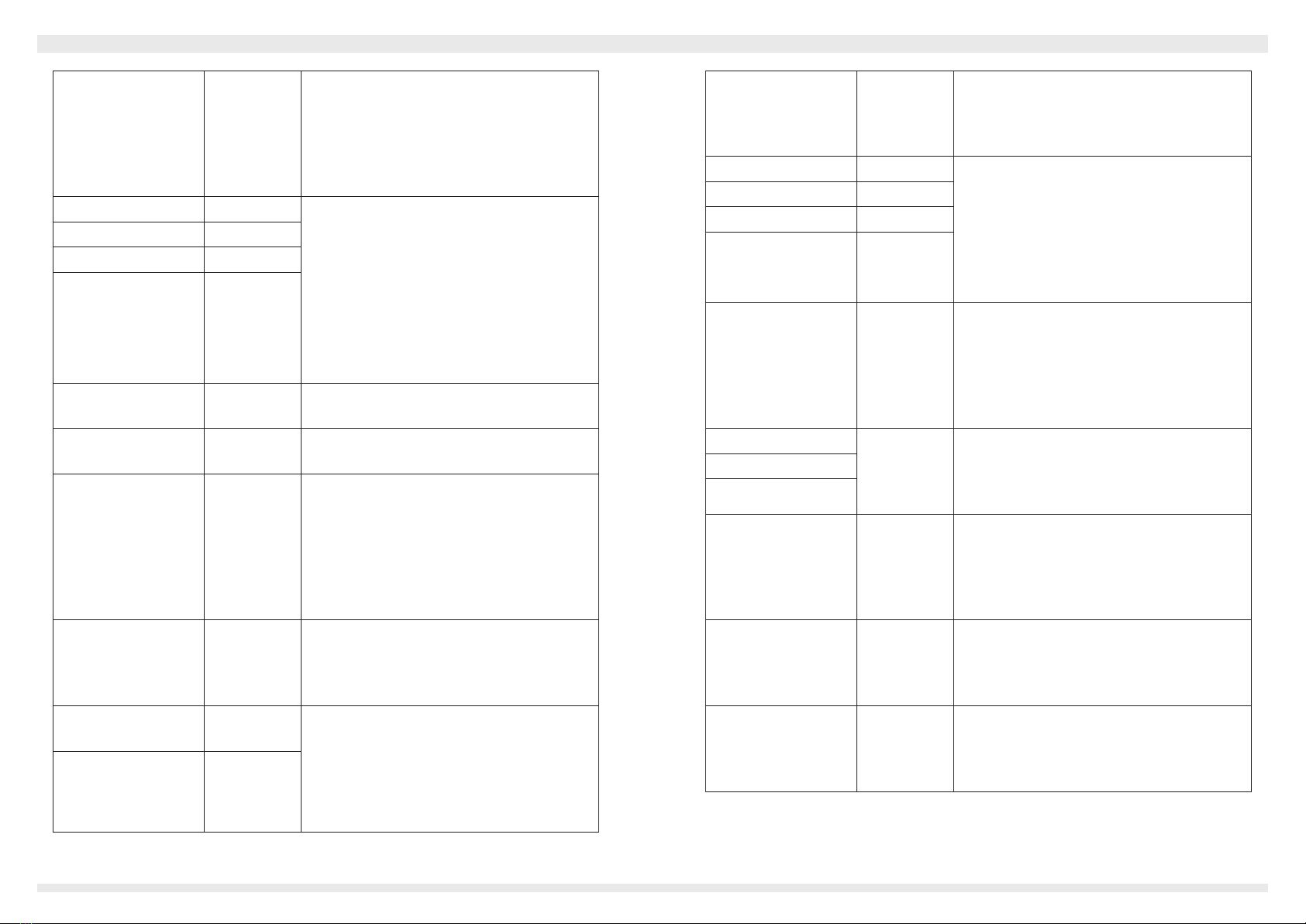

Charger Integration Options

Toenablecharging,theEVMSneedstoswitchintochargingmodebyconnectingtheCharge

Senseinputtoground/chassis.Thiswillwakeitfromsleepifneeded,poweruptheCAN

bustocommunicatewithBMSmodules,andstartthecharger.Itwillalsopreventthevehicle

frombeing accidentallydrivenoffwhileplugged into charge.Thereare severalwaysto

implementchargedetection:

Amagneticreedswitch(orsimilar)canbewiredbetweenChargeSenseand•

ground/chassis,andsetuptocloseitscontactswhenthedoor/covertothecharging

portisopened.

AnACrelaywithitscoilwiredinparallelwiththecharger’sACinput,sothatwhen-•

everthechargerhaspower,therelaywillalsoclosetoenableEVMSchargemode.

Somechargers(e.gnewerTCChargers)haveanoutput12Vsupplywhichcanbe•

usedtoswitchasmallsignalrelaytojoinChargeSensetoground/chassis.

ItisalsoessentialthattheEVMSisabletoswitchoffthechargerifanycellsexceedsafe

voltage,topreventdamagefromover-charging.Thereareseveralwaystoimplementthis:

IfusingCANintegrationwithaTCCharger,theEVMSisabletodisablethecharger•

overCANbussonoadditionalcontrolrelaysarerequired,andtheChargeEnable

outputcanbeleftunused.ToconnectaTCChargertoaZEVACANbus,join only

the CANGND, CANL and CANH pins.(Thechargeralsohasa12Vpinbutthis

shouldnotbejoinedtotheZEVACANbus,sinceitisa12Voutput,andonlythe

EVMSshouldmanage12VpowertotheCANbus.)

Manychargershaveapairofcontrolpinsthatgetjoinedtoenablethecharger.To•

usethismechanism,useasmall12VrelayswitchedbytheChargeEnableoutputof

theEVMS,withthenormallyopencontactswiredtotheenablepins.

TheAuxiliaryContactoroutputisdisabledaswellastheChargeEnableoutputif•

anycellsgoover-voltage,soifyourtractioncircuithasanyauxiliarycontactors

(andyourchargeristolerantofhavingitsDCsideinterruptedmid-charging),there

isnoneedtoaddfurtherrelays/contactorstostopthecharger,astheopeningofthe

auxiliarycontactorwillnecessarilyinterruptchargecurrent.

Thenaloption,whichcanbesafelyusedwithanycharger,istouseapowerrelay•

switchedbytheChargeEnableterminalfromtheEVMS,withtherelay’sNormally

OpenoutputswiredtointerrupttheACinputtothecharger(asshownontheex-

amplewiringdiagramonthepreviouspage).

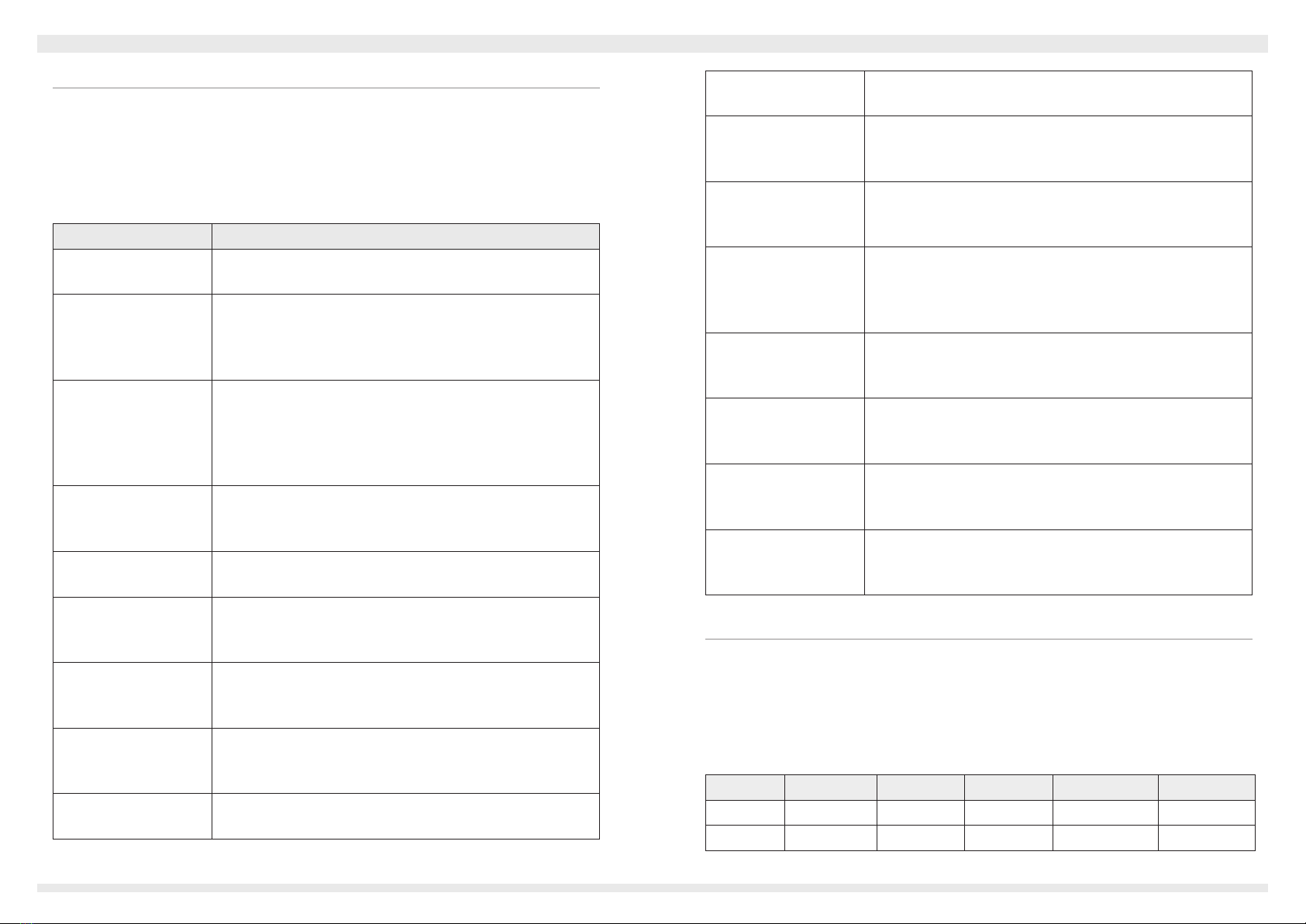

Auxiliary Contactors

Auxiliarycontactors(asshownontheexamplecircuitdiagram)areoptionalbutcanserve

severalfunctionsinanEV.

Splituphighvoltagebatterypacksintosmallergroupsofnon-lethalvoltage,orto•

isolateseparategroupsofcellsdistributedaroundthevehicle,forsafety.

Switchon/offotherHVloadsthatarebeforethemaincontactor,eitherdirectly(us-•

ingarelayswitchingpowertothedeviceitself)orindirectly(bybreakingthemain

tractioncircuit).ThemostcommonexampleistheDC/DCconverter,sothatitisnot

permanentlyin-circuit.

Effectivelyfunctioningasanautomaticmaintenanceswitch.(Ifyoudon’thavean•

auxiliarycontactorbreakingthetractioncircuitwhenthekeyisoff,itisadvisable

tohaveamanualmaintenanceswitchtodothesamejobwheneverworkingonthe

vehicle.)

87