4

Operation

The Intamix Tank Maximiser consists of a TMV with a built-in recirculation port, a cold-water T

connection and a corrugated stainless-steel hose for easy, flexible and direct connection to the

¾” male NPT threaded top connections of most water heaters.

It also uniquely features a reversible cold water/recirculation inlet connection allowing for greater

installer flexibility and a neater finish.

The TMV mixes the hot and cold water supplies and delivers a constant set temperature from the

mixed water outlet.

The Intamix Tank Maximiser allows an increased usable hot water capacity from the water heater

tank by allowing the water to be stored at a higher temperature and safely distributed at a safer

temperature by mixing the cold water and effectively increases the usable hot water capacity

of the tank. Consequently the higher potential temperature of the hot water in the tank can reduce the

risk of legionella bacteria growth in the tank.

By increasing the water temperature of the tank it also reduces the risk of legionella growth

In the event of a cold water supply failure the TMV will automatically fail-safe and shut off the supply

of the mixed water. For the fail-safe function to be guaranteed there must be a minimum temperature

differential between the hot inlet water and the mixed outlet water of 50°F.

Installation

WARNING: This product and all associated work must be performed by qualified personnel

trained in the proper application, installation and maintenance of systems in accordance with

all applicable codes and ordinances.

WARNING: If this product is not installed, commissioned and maintained correctly according

to these instructions in this manual then it may not operate correctly and could endanger the

user.

WARNING: The system must be inspected to ensure that the operating conditions are within

the specification range of the Intamix Tank Maximiser before it is installed. Conditions outside

of the specification range will invalidate the warranty and prevent proper function of the

product.

Prior to installation, the system must be drained and flushed to remove any debris.

Appropriately sized filters must be installed at the inlet from the main water supply.

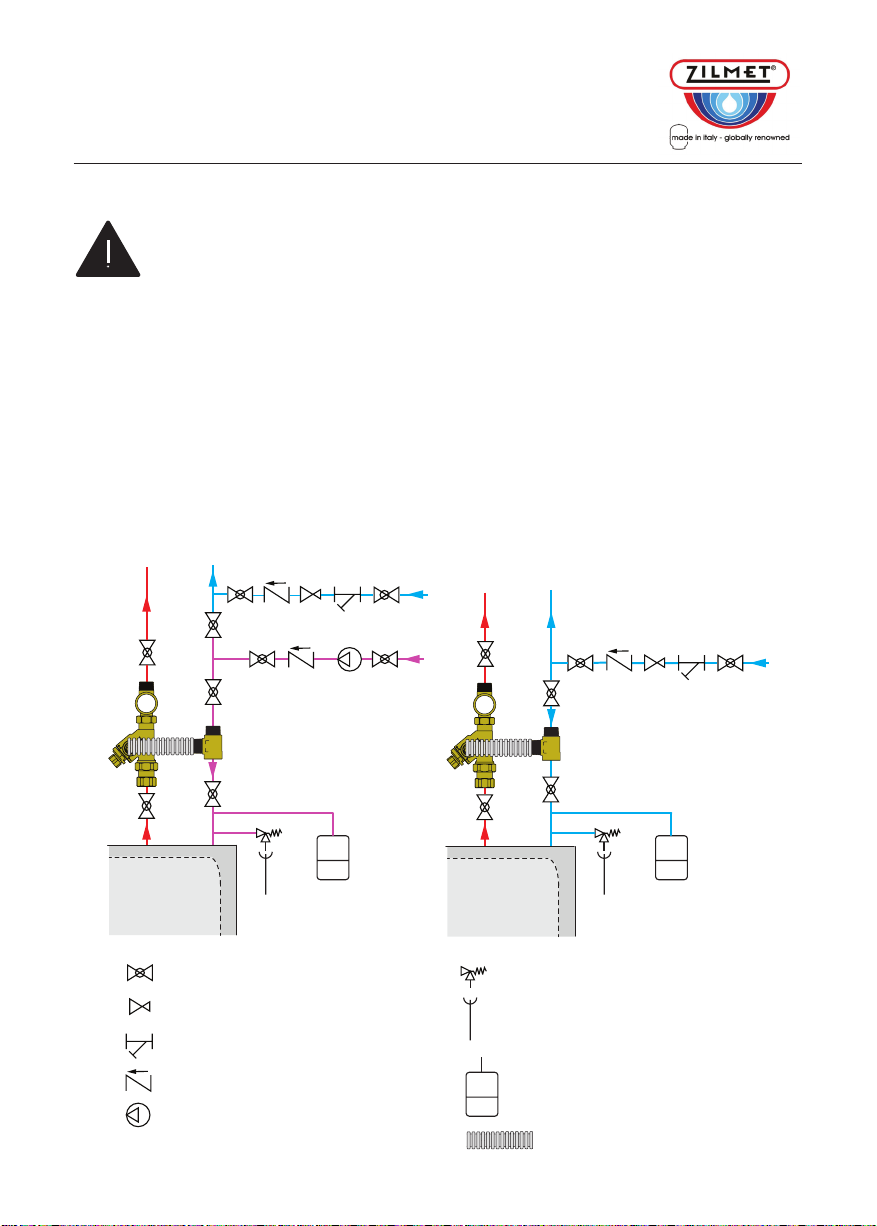

The Intamix Tank Maximiser must be installed by qualified personnel according to the diagrams in this

instruction manual and according to all applicable standards, codes and ordinances.

Consideration must be given to the water quality and if in excess of 10 grains of hardness then an

Activflo water condition is recommended to be fitted to assist in preventing excessive limescale.

For information on the ActivFlo please visit:

zilmetusa.com/installation-manuals-and-product-certifications

or scan the QR code opposite using your smart device.