INSTALLATION AND OPERATING INSTRUCTIONS: Rotary distributor, pneumatic/electric, DVR series

3

DDOC00222 / e

EN / 2020-01-21

Zimmer GmbH ●Im Salmenkopf 5 ●77866 Rheinau, Germany ●+49 7844 9138 0 ● +49 7844 9138 80 ●www.zimmer-group.com

Contents

1 Supporting documents.......................................................................................................................................................4

1.1 Hazard levels of warning notices ..................................................................................................................................................................... 4

2 Safety notices ......................................................................................................................................................................5

3 Proper use............................................................................................................................................................................5

4 Personnelqualication .......................................................................................................................................................5

5 Product description.............................................................................................................................................................6

5.1 Forces and torques ...........................................................................................................................................................................................6

5.2 Type plate ......................................................................................................................................................................................................... 6

5.3 Protection class.................................................................................................................................................................................................6

5.4 Function .............................................................................................................................................................................................................6

5.5 Product design..................................................................................................................................................................................................7

6 Accessories/scope of delivery ...........................................................................................................................................7

7 Technical data......................................................................................................................................................................7

8 Installation............................................................................................................................................................................8

8.1 General installation information .......................................................................................................................................................................8

8.2 Installing the product ........................................................................................................................................................................................8

8.3 Installing the product on the robot .................................................................................................................................................................. 9

8.4 Installing the product on the tool .....................................................................................................................................................................9

8.5 Installing the electrical system .......................................................................................................................................................................10

8.5.1 Installing the wiring .........................................................................................................................................................................................10

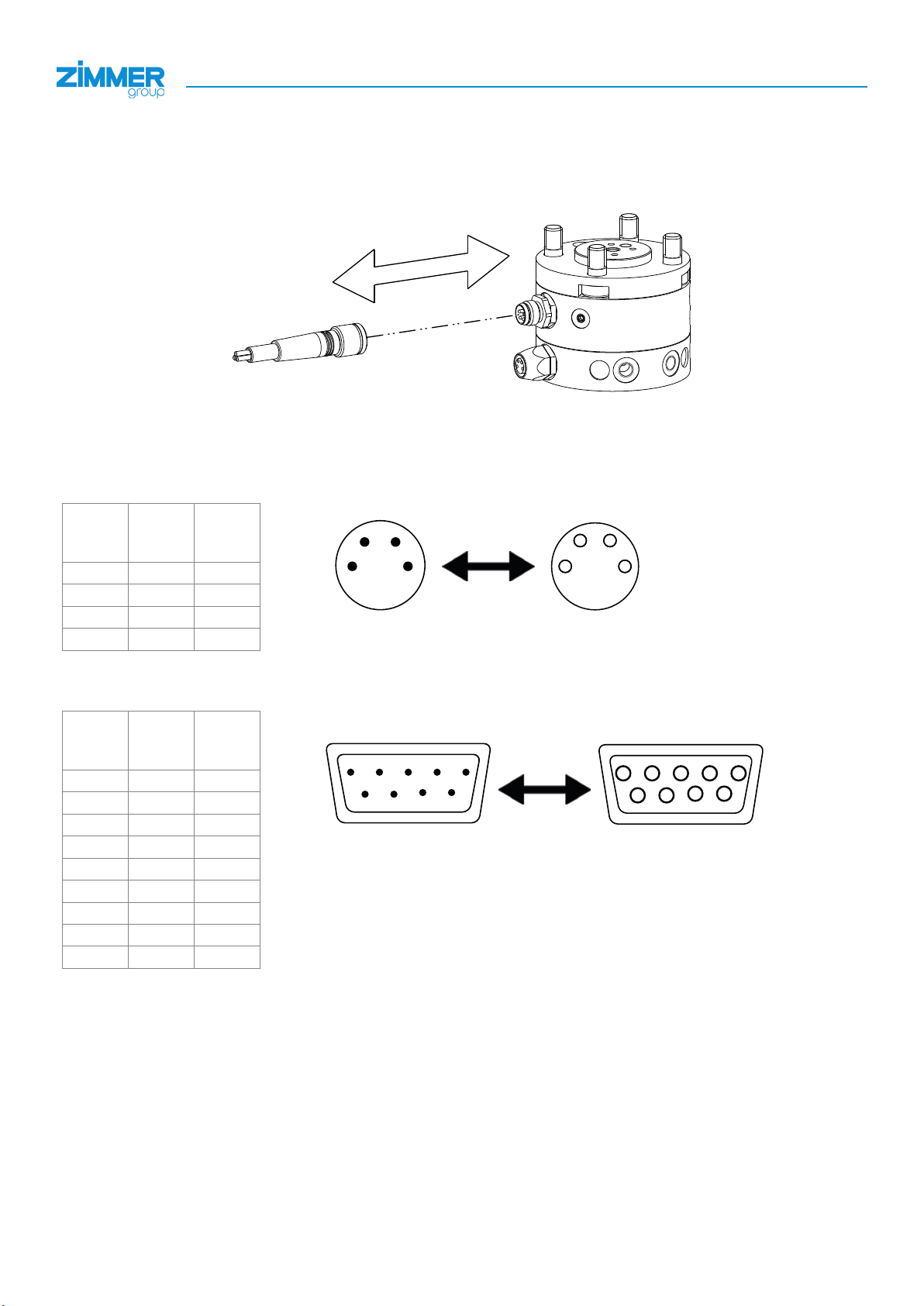

8.5.2 PIN assignment ...............................................................................................................................................................................................10

8.6 Installing the pneumatic system ....................................................................................................................................................................12

8.7 Connecting the sealing air..............................................................................................................................................................................12

8.8 Installing accessories .....................................................................................................................................................................................12

8.9 Installing the torque brace..............................................................................................................................................................................13

9 Disassembly.......................................................................................................................................................................13

9.1 Safety notices ..................................................................................................................................................................................................13

10 Maintenance ......................................................................................................................................................................14

11 Transportation/storage/preservation ..............................................................................................................................14

12 Decommissioning and disposal.......................................................................................................................................14

13 RoHS declaration ..............................................................................................................................................................15

14 REACH declaration ...........................................................................................................................................................15

16 Declaration of Incorporation.............................................................................................................................................16