997-532-000-1, Issue 1

March 2006

i

EN54 & ISO 7240 2-8 Zone Conventional Fire Panel - Installation & Configuration Manual

Contents

1 Introduction

1.1 Manual Purpose.............................................. 1

1.2 System Design & Planning.............................. 1

1.2.1 Personel..................................................... 1

1.3 General ........................................................... 1

1.4 CE Marking ..................................................... 2

1.5 EN54 & ISO 7240 Functions ........................... 3

1.6 Ancillary Functions .......................................... 4

1.7 Related Documents ........................................ 4

1.8 Warnings & Cautions ...................................... 4

2 Installation Guide

2.1 How to Use this Guide .................................... 5

2.2 Pre-installation Check List .............................. 5

2.2.1 Some Panel DO’s and DON’Ts .................. 5

2.3 Transient Protection ........................................ 6

2.4 Product Inspection .......................................... 7

2.4.1 Checking Your Panel for Damage .............. 7

2.4.2 What to do if Your Panel is Damaged .............. 7

2.5 InstallationPreparation ................................... 8

2.5.1 Removing the Cover .................................. 8

2.5.2 Back Box Fixing ......................................... 8

2.6 Optional Equipment ........................................ 9

2.6.1 2-Way Relay PCB ...................................... 9

2.6.2 8-Way Relay PCB ...................................... 9

3 Cabling

3.1 Cabling Instructions ...................................... 10

3.1.1 Cable Terminations ...................................11

3.2 Quality of Cable and of Cable Installation...........11

3.3 EMC Considerations ..................................... 12

3.4 Cables for Sounder Circuits .......................... 12

4 Field Devices

4.1 End-of -Line Devices..................................... 13

5 Panel Electronics

5.1 Main PCB...................................................... 14

5.2 PSU PCB ...................................................... 15

5.3 Label Inserts ................................................. 15

6 Commissioning

6.1 Introduction ................................................... 16

6.2 Preliminary Checks ....................................... 16

6.3 External Wiring ........................................ 16

6.3.1 Zone Wiring - New Installation ................. 16

6.3.2 Zone Wiring - Retrofit Installation............. 16

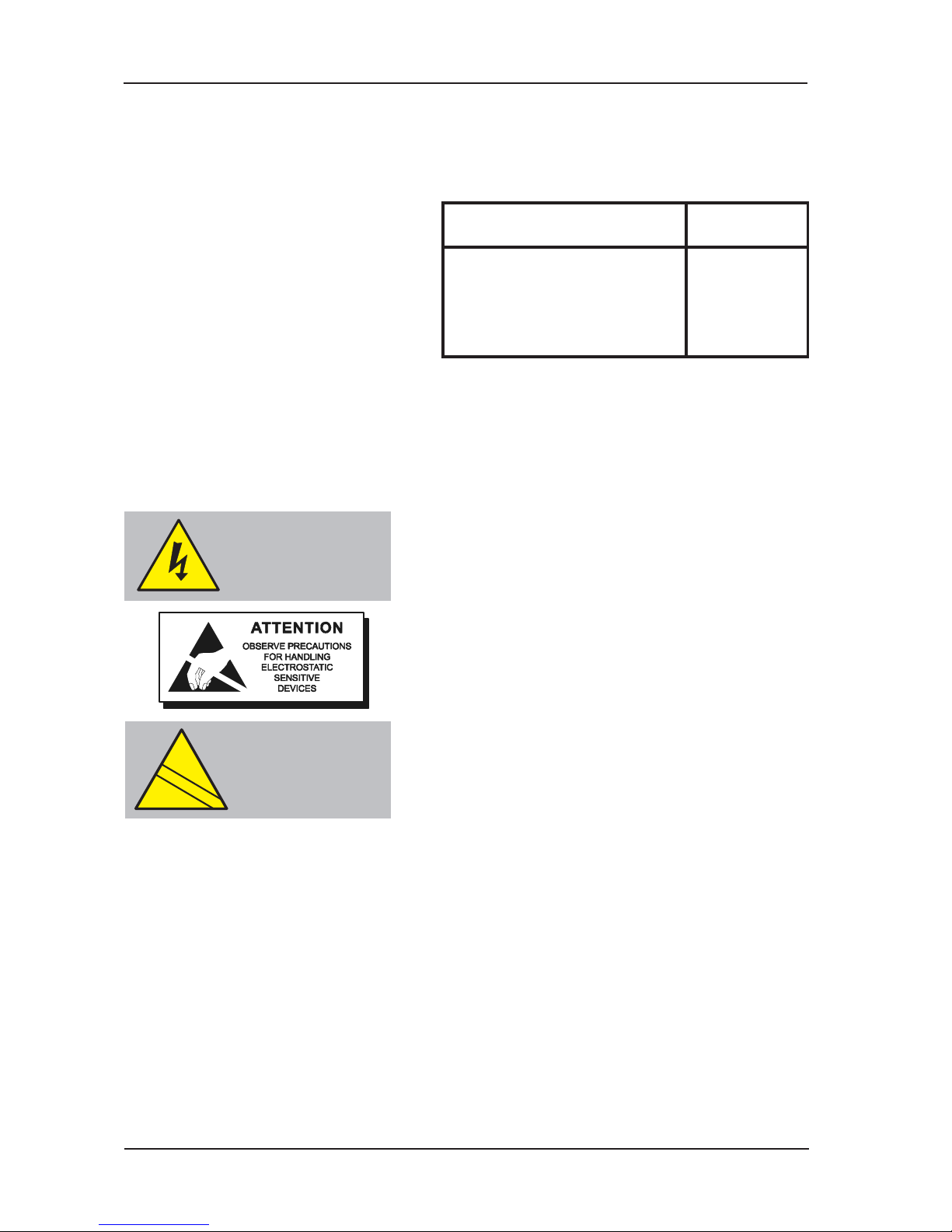

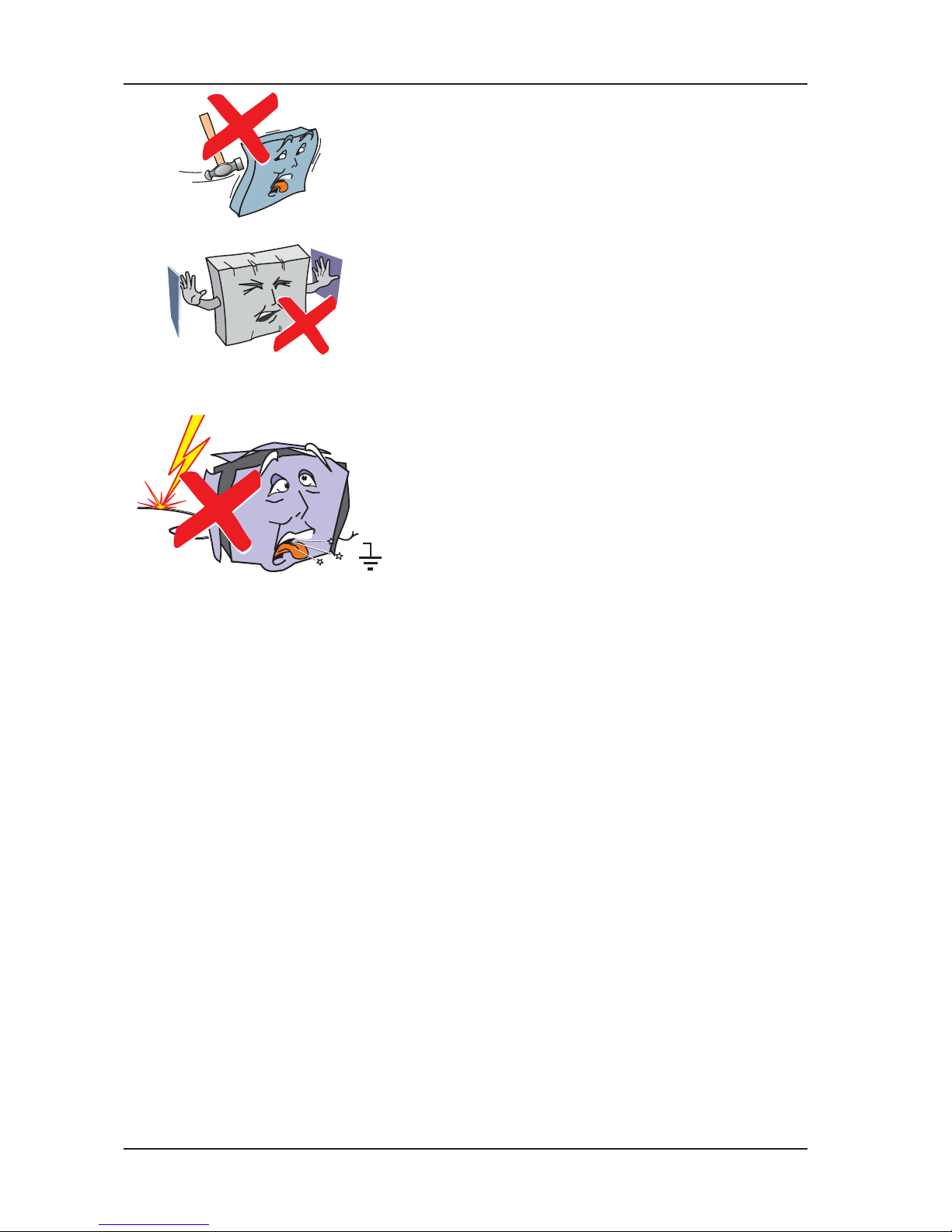

The following markings are used either on

thepanelhardwareorinthedocumentation.

They have the following meaning:

WARNING: Risk of electric shock.

Before working on mains

connections, ensure mains

power supply to the panel

is disconnected.

CAUTION: Refer to the accompanying

documentation. (When

used in the documentation,

this marking is normally

associated with additional

instructions).

!

EN54

ISO 7240