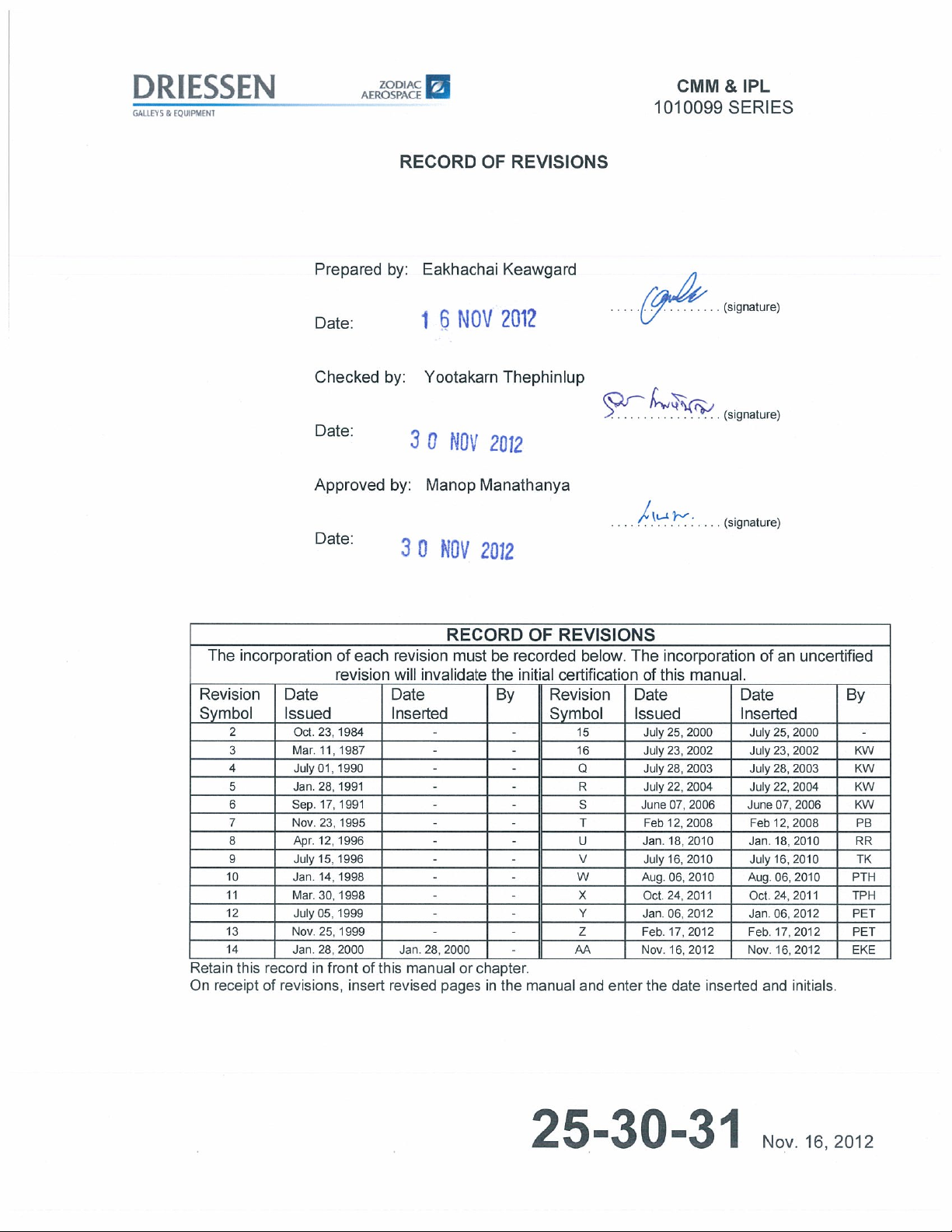

25-30-31 Oct. 24, 2011

CMM & IPL

1010099 SERIES

Page 1001

TESTING AND TROUBLE SHOOTING

1 GENERAL

This chapter outlines procedures based on test point/location methods for bench/shop testing and

trouble shooting of the rapid water heater.

2 OPERATIONAL TESTS (Ref. Fig. 102)

A. Heating elements circuit (Ref. Items 1 through 17)

(1) Circuit function

(a) Heating elements (11,12,13) are activated/deactivated by the power switch (4) via

the relay (2).

(b) The relay is controlled by a thermostat (6) to control the operation of the heating

elements (11,12,13).

(2) Check procedure

(a) Connect water heater to bench power supply (Ref. Fig. 101).

(b) Set power switch (4) to ON position.

(c) Observe current consumption of phases A, B and C on test bench ammeter. Phase

currents must be 14.5 ± 0.2A. If the phase currents are different, relevant heating

element A, B or C is defective. Replace heating element.

(d) Power lamp white (10) and lamp amber (8) illuminated, no readout on ammeters.

Heating elements (11,12,13) are defective and have to be replaced or relay (2) is

defective and has to be replaced.

(e) Lamp white (10) illuminated, lamp amber (8) extinguished, no readout on the

ammeters. Overheat protector is activated or relay or the thermostat is defective.

Reset overheat protector (5) or replace relay (2) or thermostat (6).

B. Lamps (Ref. Items 8,10)

(1) Circuit function

(a) Lamps (8,10) illuminate when power switch (4) is set to ON position.

(2) Check procedure

(a) Use power switch (4) to switch on a cold rapid water heater.

(b) If lamp amber (8) or lamp white (10) does not illuminate, bulb (9) is defective.

Replace relevant bulb.