5

© Copyright 2019 Zoeller®Co. All rights reserved.

Assembly Procedures

assembly(3). Theassembly consists ofthepower cord, thewireterminals,

and the cord seal assembly.

1. Unroll the cord of the cord terminal and seal assembly (3)

2. Install gasket (6) on top of motor housing (11).

3. Suspend the cord and cover assembly over the motor housing and

make wiring connections per the proper wiring diagram (page 7).

4. Tuck the wires in the cover assembly as installing the cover into place.

5. Secure the cover (5) to the motor housing (11) with four screws (33).

6. Torque screws to 63-67 in-lbs.

NOTE: Align the straight (non circular) surface of cover with the straight

surface of motor housing.

D. Installation of rotary seals and seal retainer...

Make sure all seal faces remain free of dirt particles.

Apply a light coat of oil to seal faces before installing.

1. Refer to rotary seal component placement diagram for relative

positioning of seal parts.

2. Apply Loctite # 609 to OD of SS seal cup, and using a nonmetallic

sleeve, press the seat into position in the adapter.

3. Apply oil (18) to the shaft and to the inside diameter of the rotating

section of rotary seal (20). Push the rotating section onto the shaft in

a continuous motion until the seal faces meet.

4. Install washer and retaining ring (21) in the groove of the rotor shaft.

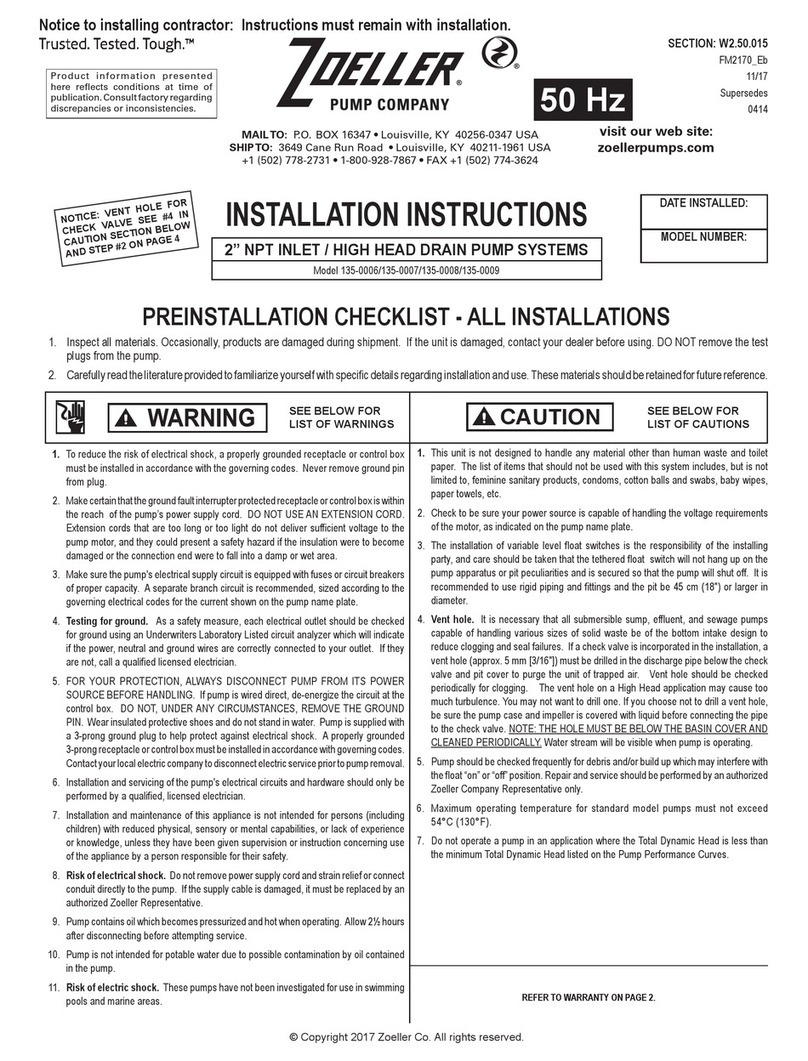

ROTARY SEAL COMPONENT PLACEMENT

DIAGRAM

E. Installing the hydraulic rotor...

1. Slide hydraulic rotor (22) onto electric rotor shaft (14)

2. Align holes in rotor to press in pin (23)

3. Use pin tool (156797) with installation driver to start pin. Drive the pin

(23) ush with hydraulic rotor.

SNAP RING

WASHER

ROTATING SECTION

STATIONARY SECTION

SPRING

SK3269

3. Lift the motor housing (11) off the adapter (19). Be careful to lift the

motor housing straight up, so as not to damage the stator windings

or bearings.

4. Remove bearing pre-load washer (12) from motor housing (11) and

inspect.

5. Remove rotor assembly (14) from adapter (19).

6. Using a bearing puller, against the inner race, remove the lower

bearing (16) and upper bearing (13) from the shaft. Replace the

bearings if needed.

NOTE: Bearings should be cleaned with volatile mineral spirits and

relubricated with proper lubricants immediately after cleaning. Never

drybearingswithcompressedair,andneverspinun-lubricatedbearings.

H. Motor Stator...

NOTE: The motor housing and stator assembly removed in Section G

number 3, is a factory assembled unit and must be replaced as such:

it consists of the motor housing, the glued in stator, and the through

wall electrical terminals for the power wires.

ASSEMBLY PROCEDURES

Pumps are reassembled in reverse order of disassembly. The following

suggestions are offered.

NOTE:Whilethepump is dismantled,allgaskets,seal rings andretaining

rings should be checked for wear and deterioration. Replace all worn

items. Ensure that all parts are thoroughly cleaned before assembly.

A. Assembly of rotor (14)...

1. Inspect rotor to see that the snap ring is in place and snapped in

thegroove. Thissnap ring servesas alocator forthe lowerbearings.

NOTE: Before installing the bearings, wipe the bearing seats on the

shaft clean and coat the seats with oil to prevent galling of the shaft

as the bearings are pressed onto the shaft. A properly sized pressing

sleeve should be used to install bearings, with pressure being applied

to only the inner bearing race.

2. Install the lower ball bearing (16) and the upper ball bearing (13)

on the rotor shaft (14).

3. Set the adapter (19) on blocks to allow the rotor shaft to clear the

work surface when installed.

4. Install the rotor/bearings assembly into the adapter housing (19).

Make sure the lower bearing is seated in the bearing pocket.

B. Installing the motor housing/stator (11)...

NOTE: The motor housing/stator assembly is furnished from the factory

as a glued-in unit. The assembly will include the motor housing, the

stator prewired to installed through wall terminals (10).

1. Lightly oil and position the seal ring (17) around the pilot shoulder

of the adapter (19).

2. Install the pre-load washer (12) in the upper bearing pocket of the

housing/stator unit (11). The pre-load washer should be stretched

a little to allow it to remain in the pocket when turned upside down.

3. With the rotor/adapter assembly in the vertical position suspend

the motor housing/stator unit over it. Slowly lower the unit aligning

the rotor and stator opening.

4. Secure the motor housing/stator (11) to the adapter (19) with four

screws (35)

5. Torque screws to 63-67 in/lbs.

C. Installing cord and cover assembly...

NOTE: The cord will come from the factory as a cord terminal and seal