Driver

-5-

Warning:

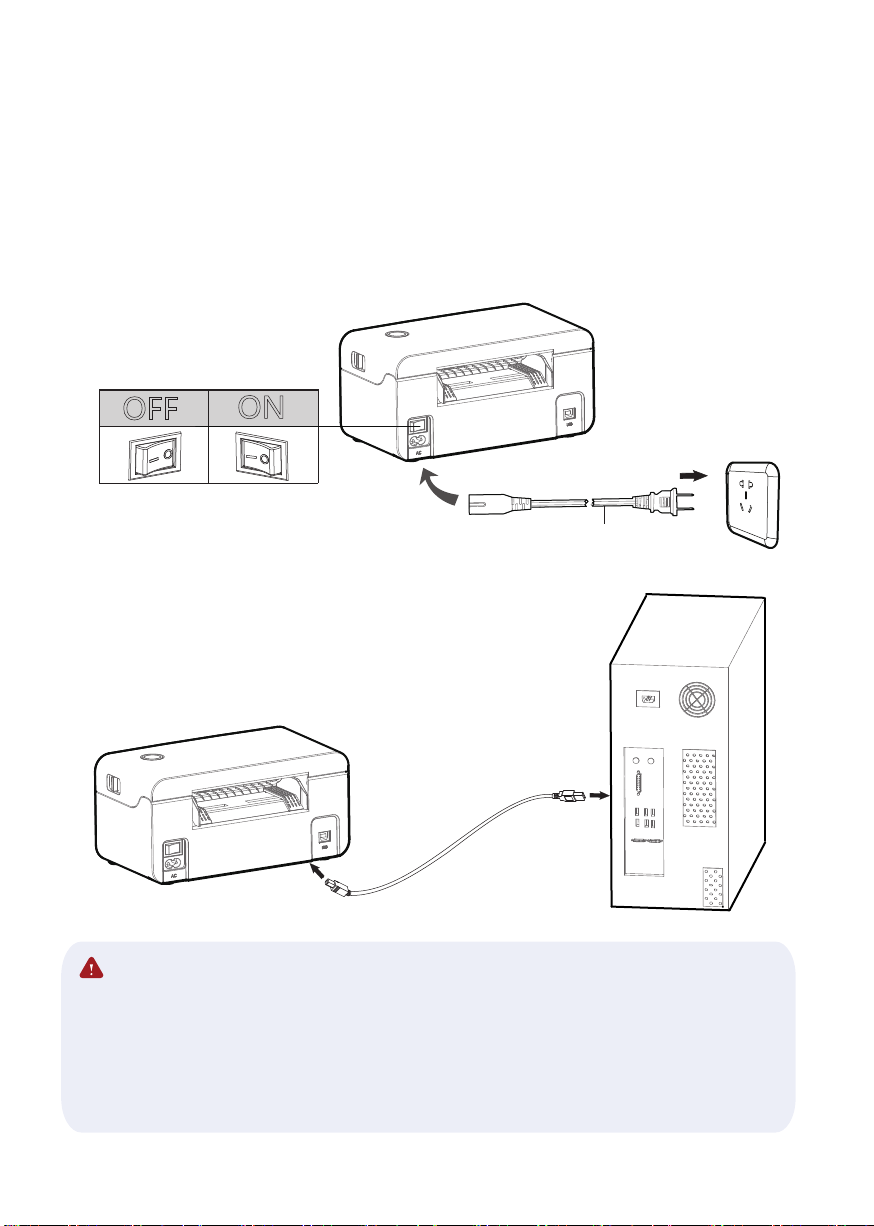

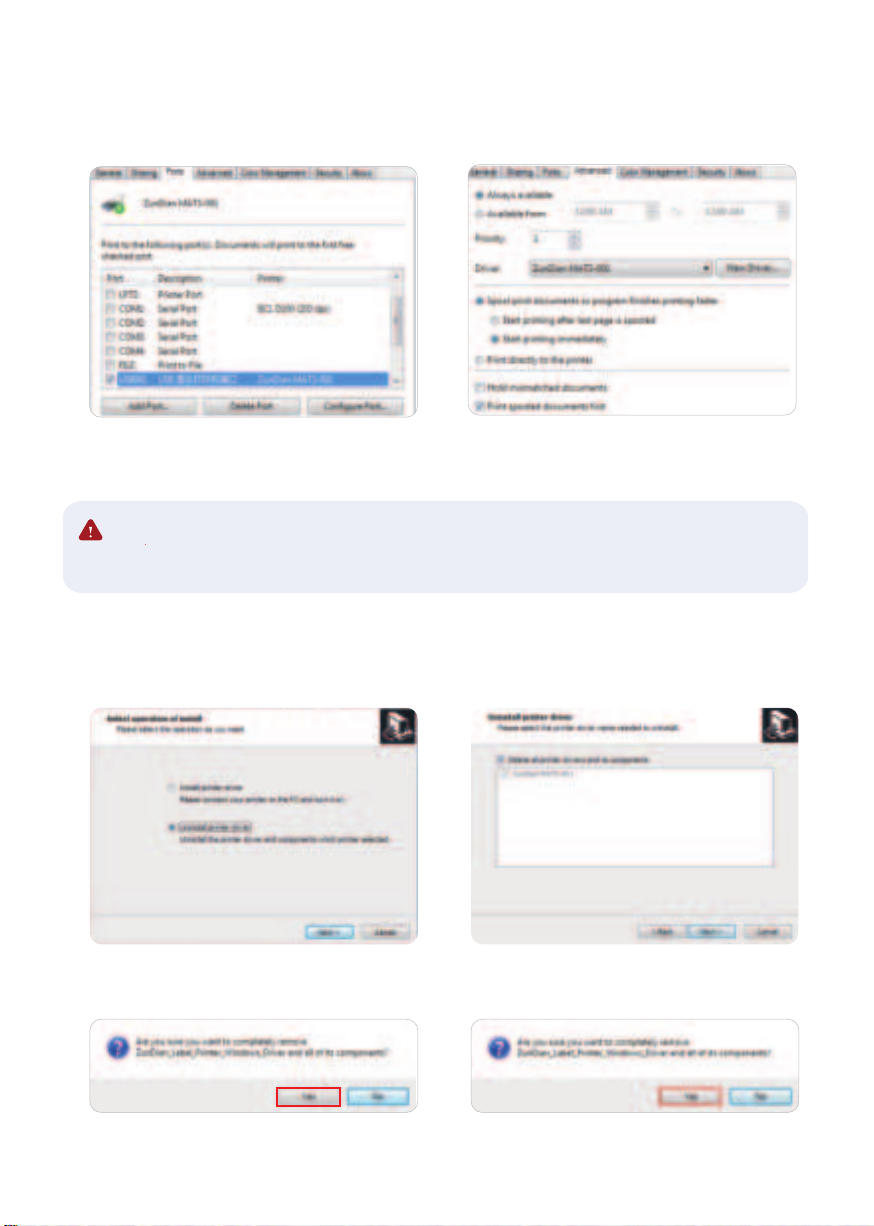

1. Select one interface to connect your printer to computer.

2. Turn on the printer and check if it is connected successfully.

3. Double click Windows Driver.

7.

http://www.zundian.site/download