PAGE 2 MAJ-14

CONTENT: PAGE:

1. INTRODUCTION................................................................................................................................. 3

2. GENERAL SAFETY ADVICE .............................................................................................................. 4

3. SAFETY SYMBOLS............................................................................................................................. 4

4. DESCRIPTION .................................................................................................................................... 6

5. ASSEMBLY.......................................................................................................................................... 7

6. WORKING PRINCIPE OF THE SPRAYER......................................................................................... 9

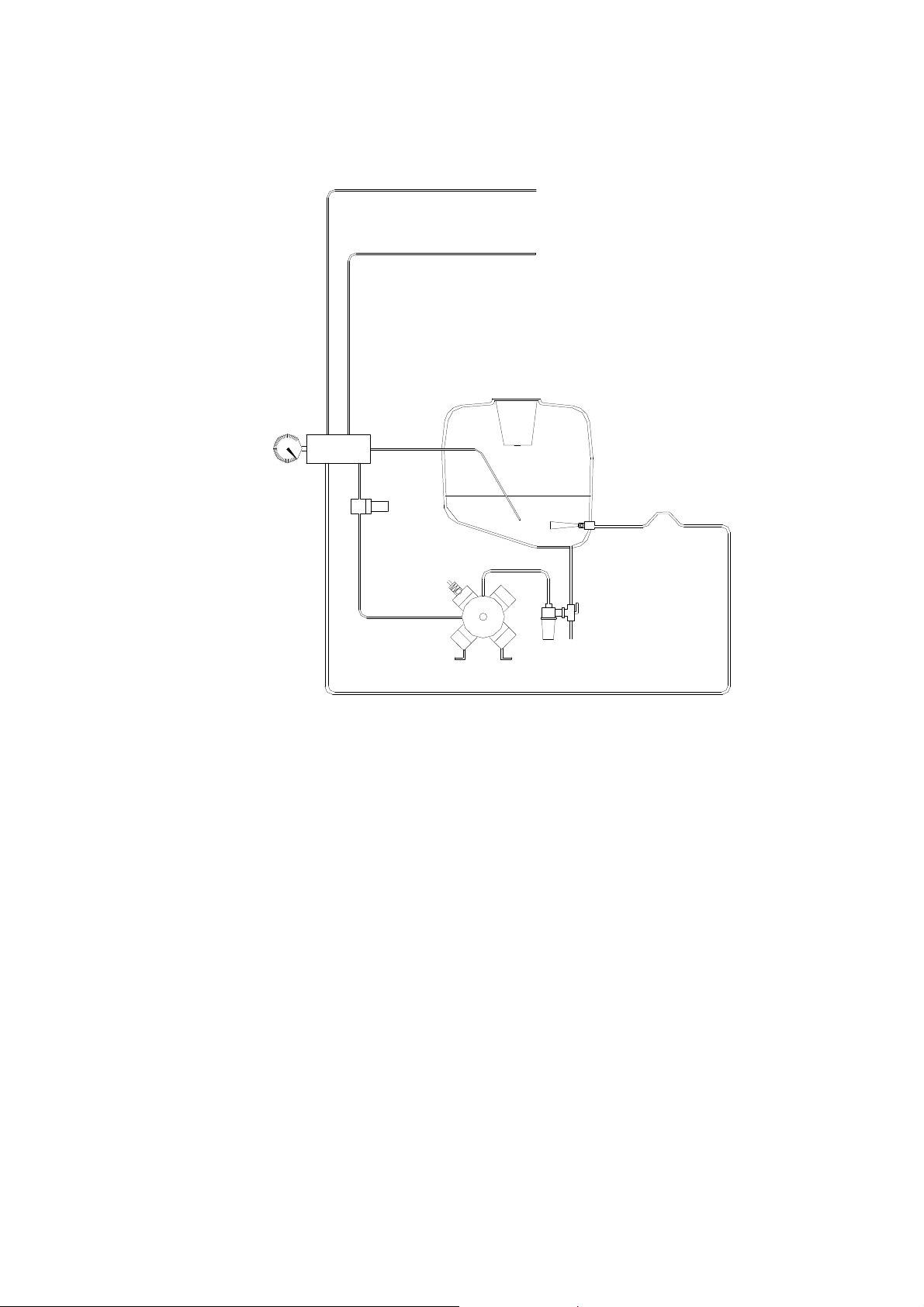

WORKING SCHEME OF THE SPRAYER..................................................................................... 10

7. BEFORE THE USAGE ...................................................................................................................... 10

8. PREPARATIONS FOR THE WORK ................................................................................................. 11

8.1. CONNECTING THE SPRAYER ............................................................................................. 11

8.2. P.T.O. CHOICE....................................................................................................................... 11

8.3. CHOOSING THE RIGHT P.T.O. LENGTH............................................................................. 11

8.4. GREASING THE P.T.O. ......................................................................................................... 13

9. FILLING AND EMPTYING THE TANK.............................................................................................. 13

10. HOW TO USE THE REMOTE UNIT ...............................................................................................14

11. WORKING WITH THE SPRAYER.................................................................................................. 15

12. CLEANING THE SPRAYER............................................................................................................ 16

12.1. REMOVING THE TECHNICAL LEFTOVER......................................................................... 16

12.2. CLEANING THE INTERIOR ................................................................................................. 16

12.3. CLEANING THE EXTERIOR OF THE SPRAYER................................................................ 16

13. CALCULATING THE AGENT CONSUMPTION ON A HECTARE..................................................17

13.1. DEFINING THE RIGHT SPEED........................................................................................... 17

13.2. DEFINING THE FLUID CONSUMPTION ON A HECTARE................................................. 17

13.3. DEFINING THE CONCENTRATION.................................................................................... 18

14. OPTIMAL WORKING SETTINGS................................................................................................... 22

15. PREPARING THE SPRAYER FOR LOW TEMPERATURES.........................................................23

16. PUMP MAINTENANCE ................................................................................................................... 24

17. OPERATIONAL PROBLEMS OF THE SPRAYER.......................................................................... 25

18. NOZZLE HOLDER........................................................................................................................... 26

19. FAN DRIVE...................................................................................................................................... 26

20. MIXING THE FLUID IN THE TANK................................................................................................. 27

21. SUCKING FILTER........................................................................................................................... 27

22. PRESSURE FILTER........................................................................................................................ 28

23. SPRAYER LUBRICATION............................................................................................................... 29

24. TECHNICAL DATA.......................................................................................................................... 30

WARRANTY .................................................................................................................................. 31

SERVICE ....................................................................................................................................... 31

25. ADDITIONAL EQUIPMENT............................................................................................................. 32

25.1. ONE HAND UNIT.................................................................................................................. 32

25.2. PUMP AR 503....................................................................................................................... 33

25.3. DOUBLE NOZZLE HOLDERS.............................................................................................. 34

25.4. ACCESSORY FOR TERRACE SPRAYING......................................................................... 34