2

TECHNICAL DATA

Before proceeding to assembly,

please make sure all the

following conditions are veried

• Max. water pressure endured: 6 bar

• Recommended ow rate: 12,5L/min

• Maximum ow rate: 25,0 L/min

• Max. water temperature: 60ºC

• Min. height clearance: 90mm

INSTALLATION INSTRUCTIONS

Zypho® S|im Heat Exchangers are provided

as a complete bundle.

Please check the content of the package for

completeness and integrity before proceeding.

Should any deviations be noted, please consult your

supplier and do not start the assembly. You must never

alter or modify the provided components by Zypho®. For

a proper installation, please use these components only.

Before the freshwater connection a non-return valve and

a shut-o valve should be installed (type EA).

We recommend the use of a thermostatic shower mixer.

NON-COMPLIANCE WITH THESE RECOMMENDATIONS

FOR INSTALLATION AND USE MAY VOID ANY WARRAN-

TY.

SAFETY

Zypho® S|im Heat Exchangers are double walled,

according to European regulation EN 1717 (“Protection

against pollution of potable water in water installa-

tions and general requirements of devices to prevent

pollution”).

We test all Zypho® units in our factory before shipping.

The main water circuit is pressurized up to 9 bar to ensu-

re that there are no leaks or defects.

MAINTENANCE

Zypho® S|im Heat Exchangers have been designed to

require minimal maintenance eorts.

They must be installed with the shower drain provided.

Periodic cleaning is recommended to optimise energy

exchange. Use a non-corrosive drain cleaner or a water

jet. We recommend our water jet brush ZYMN00000J1.

IMPORTANT REMARKS

INSTALLATION

The preheated water supply inline of the ZYPHO S|im

must be insulated in accordance with the requirements

of the ‘Building Services Compliance Guide’.

Pipework between the WWHRS preheated water outlet

and the water heater and /or shower cold water inlet(s)

(depending on installation conguration) must be

labelled to indicate that no other services can be inter-

connected.

System A: Installation conguration 1

System B: Installation conguration 2

System C: Installation conguration 3

Energy Saving Performance Recognised by SAP

The successful operation of the ZYPHO S|im which is a

Waste Water Heat Recovery System (WWHRS) – Instan-

taneous Shower Heat Recovery Device, depends entirely

upon the adherence to these instructions. Additionally,

for new-build dwellings within the UK, recognition of the

system’s energy saving performance within the National

Calculation Methodology (NCM) for the energy rating of

dwellings, known as the Standard Assessment Proce-

dure (SAP) requires that these instructions are complied

with in conjunction with a system design checklist and an

installation checklist and certicate of installation,

supplied with this document and available at:

www.ncm-pcdb.org.uk/sap.

The system should be installed by a suitably qualied

plumber, with system design consideration being equally

important to a correct installation. For recognition of the

ZYPHO S|im within SAP, a system design checklist and

an installation checklist and certicate of installation

should be completed and signed, with copies kept for the

home user pack (home owner), the installer, and sent

to ZYPHO at the post or e-mail address shown below.

Building Control Ocers may also request a copy. For the

purpose of system identication of product data without

SAP, the product will have an NCM (SAP) Identier label

permanently xed to the unit, whereby the ‘model qua-

lier’ states ‘refer to installation certicate, if unknown

assume System B’. A second NCM (SAP) Identier label

is also supplied and must be axed to a nearby boiler or

service cupboard (the label must be visible for inspec-

tion without disassembly of nearby products or

systems) and the ‘model qualier’ states ‘System A,

System B or System C delete as appropriate’.

Not sending back the completed and signed system

design checklist, the installation checklist and certicate

of installation to ZYPHO will invalidate the guarantee.

Address

Rua Barão do Corvo, 37 – 1°F

4400-039 V N Gaia, PORTUGAL

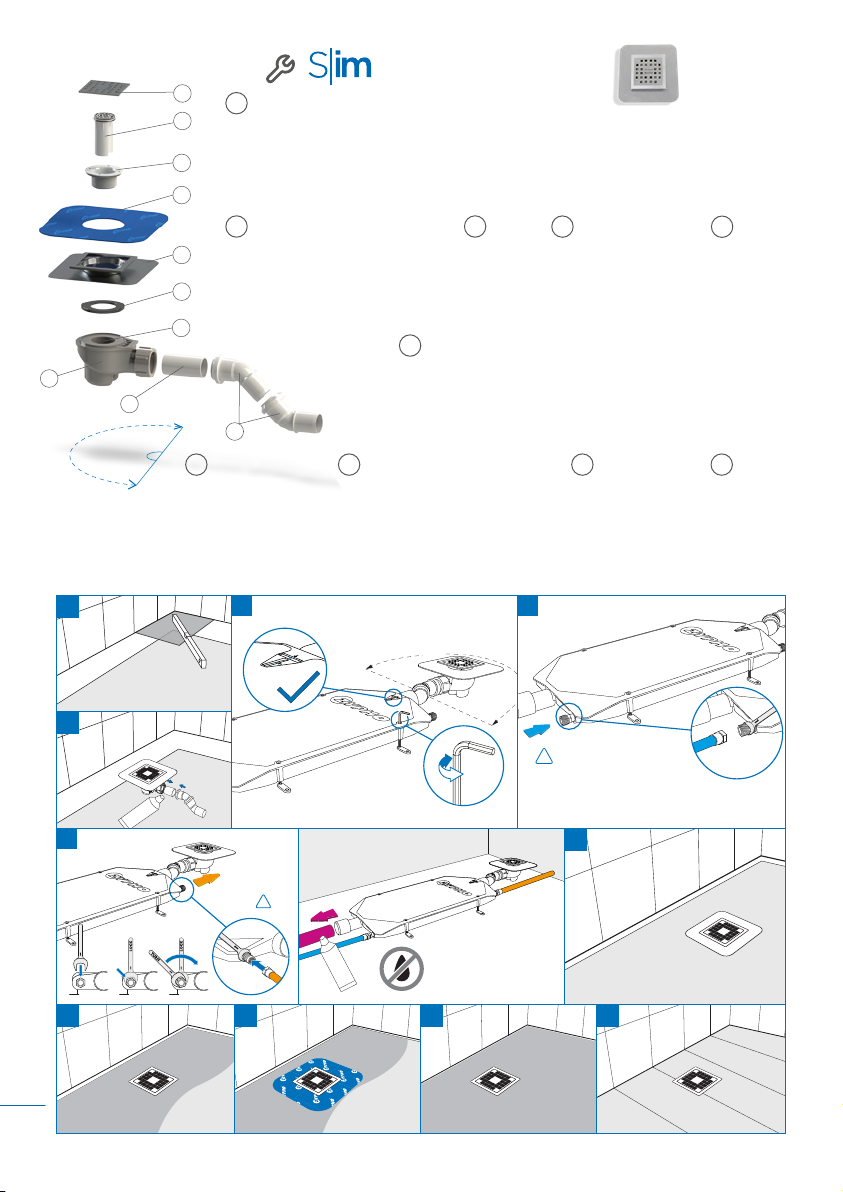

COMPONENTS AND DIMENSIONS P. 9

INSTALLATION CONFIGURATION OPTIONS P. 8 INSTALLATION GUIDE P. 10,13