1-CUBE GMD User manual

Hamry 3567, 580 01 Havlíčkův Brod, Czech Republic

tel. +420 569 433 620, fax +420 569 422 144

GMD and

GMDK

MEASURING DEVICE OF CO2 CONTENT IN FERMENTING

TANKS AND KEG CASKS

USER’S GUIDE

2

3

Content:

1.0 Range of supply and device application ................................................................................................................. 4

2.0 Installation - putting the device into operation and its maintenance ........................................................ 5

2.1 Ta ing of samples ........................................................................................................................................................ 6

2.2 Discharging of the sample ........................................................................................................................................ 7

2.3 Cleaning of the device ................................................................................................................................................ 7

3.0 Safety recommendations ............................................................................................................................................... 7

4.0 Technical data .................................................................................................................................................................... 8

5.0 Operating instructions ................................................................................................................................................... 8

5.1 Measurement procedure .......................................................................................................................................... 8

5.1.1 Ta ing of samples ............................................................................................................................................... 8

5.1.2 CO

2

Content measurement .............................................................................................................................. 9

5.1.3 Discharging of the sample ............................................................................................................................ 10

5.1.4 Cleaning of the device..................................................................................................................................... 10

5.2 Control of the electronics ...................................................................................................................................... 11

5.2.1 Switching ON and OFF the device ............................................................................................................. 11

5.2.2 Charging of the device .................................................................................................................................... 11

5.2.3 CO

2

Content measurement ........................................................................................................................... 12

5.2.4 Reading recorded values of CO

2

from memory ................................................................................... 13

5.2.5 Deleting the content of the memory ........................................................................................................ 13

6.0 CO

2

transferring measured values from memory to PC computer(type GMDK only) ..................... 13

7.0 Service ................................................................................................................................................................................ 14

4

1.0

R

ANGE OF SUPPLY AND DEVICE APPLICATION

Standard range of supply:

GMD (GMDК)device ........................................................................................ 1 unit

adapter AC/DC GMD (GMDК) ..................................................................... 1 unit

tubes – length about 1 m GMD (GMDК) ................................................ 2 units

cable RS485/USB FTDI USB-RS485-WE-1800-BT

for connection to PC (only for type GMDК) ......................................... 1 unit

DVD with DataViewer software for PC (only for type GMDК) ...... 1 unit

Optional accessories:

withdrawal head for egs ............................................................................. 1unit

Note: accessories is not part of the supply - only on customer’s demand

GMD is a measuring device for measurement of CO

2

content in beer, soft drin s and mineral water

in tan s and KEG cas s.

Note: Adapted only for industrial application

Whenever in the future GMD unit can be upgraded to GMDK unit if required.

With the comfortable version GMDK, the CO

2

measurement can be transferred to PC. The results

can be displayed on graph and saved into files, useful for further, deeper analysis.

5

2.0

I

NSTALLATION

-

PUTTING THE DEVICE INTO OPERATION AND ITS

MAINTENANCE

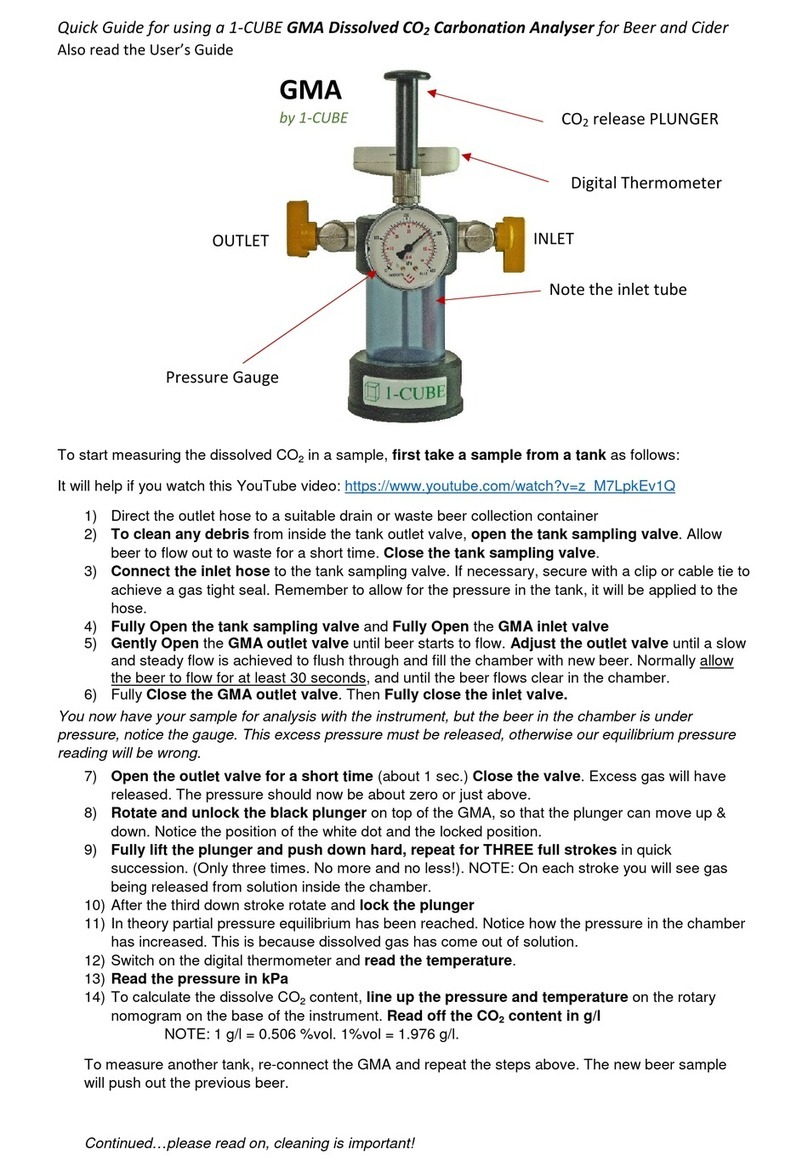

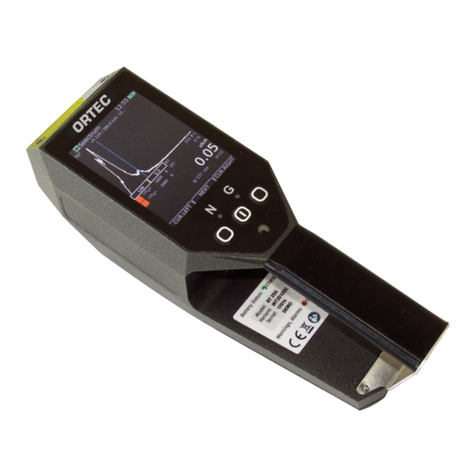

Pic.1 GMD et

front view rear view

2 8 9 4 1 3 3 1 4 12 13 6 5 2

Pic.2 Button po ition

10 11

6

Explanation: 1. Inlet valve, 2. Outlet valve, 3. Inlet hose 4. Stainless steel tube, 5. Outlet hose, 6.

Transparent vessel, 7. Bottom of the vessel, 8. Keyboard with display, 9. Button, 10 Down position,

11. Upper position, 12. Power button, 13. Connector cover

2.1

T

AKING OF SAMPLES

The device is ready for measurement at the moment of delivery.

Preceding the own measurement connect the device by fixing of inlet hose (3) to the sampling

point. The measured sample must flow through stainless tube (4) to the bottom of the vessel. The

inlet hose (3) must be secured at the sampling point not to fall out during ta ing of sample under

pressure.

7

2.2

D

ISCHARGING OF THE SAMPLE

Close the sampling valve on the tan , then open both inlet and outlet valves to remove any pressure

inside the hoses and the GMD. Then disconnect the inlet hose (3), place the outlet hose (5) to the

drain and turn the device upside down. At the same time hold the inlet hose (3) 10 cm over the

device. Chec visually if the transparent vessel (6) is empty.

If you are going to measure other samples, you don’t need to empty the GMD. You can rinse the old

sample with the new one by leaving the new beer flowing through the GMD about 30 s.

If you have finished measurement, clean the device. Rinse the device with clean water.

2.3

C

LEANING OF THE DEVICE

Open the inlet valve (1) and the outlet valve (2). Place the outlet hose (5) to the drain. Connect the

inlet hose (3) to the potable water supply. Afterwards open slowly the water coc and rinse the

device with water. Both ball valves (1,2) have to be open during rinsing.

Warning! Pressure of water must not exceed value 250 Pa.

Whole internal space of the vessel (6) must be filled with water during cleaning. During rinsing pull

out and consequently press down several times the button (9) to rinse both pump and capillary.

It is important to remove any traces of beer to prevent the piston getting stuc .

After rinsing:

Once the cleaning is over, switch off the water coc . Disconnect the inlet hose (3) from the water

coc . If you plan to use the device next day, do not discharge the water from the device and pull up

the button (9) to suc the water inside the pump.

If you want to discharge the water then place the outlet hose (5) to the drain and turn the device

upside down. At the same time hold the inlet hose (3) 10 cm over the device. First open the outlet

valve (2) and subsequently open the inlet valve (1) and discharge the water. Chec visually if the

graduated vessel (6) is empty.

Clean the external surface with soft flannel moistened with water. After this handling the device is

ready for next measurement.

The unit must not squirt water!

3.0

S

AFETY RECOMMENDATIONS

Measuring device of CO

2

content - types GMD (GMDK) may be operated only by person who

became completely acquainted with its function within the framewor of the training, or who

became thoroughly acquainted with the user’s guide of this device.

8

Measuring device GMD (GMDK) can be used only for determination of CO

2

content in the range of

measured values determined by technical conditions. Never connect the measuring device to the

withdrawal spots where measured parameters are over measuring capacity of the device.

Chec device before each measurement. Do not use visibly damaged device and contact the

qualified service personnel who provides service for delivered device.

Warning! It is forbidden to use the device for pressure higher than 600 Pa and for temperature

higher than +30 degrees Celsius. It could cause device destruction and staff injury.

4.0

T

ECHNICAL DATA

range of CO

2

measurement ....................... 2.0 – 9.99 g/l or in mass percentage 0.2 – 0.99 m%

range of temperature

measurement ..... 0 – +30 °C

range of pressure

measurement ............. 0 – 600 Pa

accuracy of CO

2

content measurement. ± 0.1 g/l or in mass percentage ± 0.01 m%

accuracy of temperature measurement ± 0.1 °C

accuracy of pressure measurement ....... ± 0.5 %

dimensions ....................................................... 280x180x300 mm

weight (of empty device) ............................ about 1.5 g

protection .......................................................... IP 54 (with threaded cover on connector)

5.0

O

PERATING INSTRUCTIONS

5.1

M

EASUREMENT PROCEDURE

You can see the instruction video on:

https://youtu.be/XRgAYRne3HM

5.1.1

T

AKING OF SAMPLES

Measuring device for measurement of CO2 content in beer, soft drin s and mineral water in

cylindro-conical fermenters, tan s and KEG cas s completed with withdrawal head for egs

(Optional accessories).

Chec device before each measurement. Do not use visibly damaged device.

Notice! Sludge the sampling point before connecting the device. Sludge the sedimented yeast to

fill inside the chamber only beer without sedimented yeast!

9

Chec button (9) on the top of the device if it is in secured position (10b). Afterwards connect the

device by fixing of inlet hose (3) to the sampling point. The inlet hose (3) must be secured not to

fall out with the pressure.

If there is a big difference in diameters of the hose and sampling valve, use a reduction in the

supplied hose and the other one in another hose satisfactory for safe sampling. We recommend to

fix the hoses on the reduction with clamps.

Place the outlet hose (5) to the drain, the inlet valve (1) is shut during this handling. Afterwards

open fully the valve of the sampling point and let beer or saturated beverage go into the inlet hose

(3) to inlet valve (1). Open fully the inlet valve (1) on the device.

5.1.2

CO

2

C

ONTENT MEASUREMENT

Open both valves (1), (2) to let the sample fill in the transparent chamber (6) SLOWLY, to avoid

foam creation.

Let the beer flow through the device for at least 20s, 30s or more if you are rinsing the sample from

a previous measurement or if it’s the first measurement and the GMD was stored in a warmer place

before.

Fill the transparent chamber (6) completely with the sample. Chec visually if there is no foam or

bubbles inside the chamber (6)!

The device is on the ground during ta ing of sample.

Now first shut the outlet (2) valve, then the inlet (1) valve. Press the power button (12) to turn on.

Switch on the microcontroller by pressing the On ey and when the device is ready, press the Enter

ey. The GMD starts measuring continuously the pressure and waits for depressurization. You have

to open the outlet valve (2) to remove the overpressure from the tan . Open it slowly and close it

immediately after hearing the sound emitted by the buzzer and the display shows "close v.", which

indicates that the pressure is under threshold level. Then push out the button (9) of the secured

position (10b) and pull it out into the upper position (11) (loo pic.2). Hold it for a while in this

position to equalize the pressure. Then press down the button (9) to the very down unsecured

position (10 a). After this handling dissolved CO

2

is fluttered and the pressure increases in the

chamber (6). Repeat this action one more time.

You should not pump more than three times to get good results and a good repeatability.

If the device was stored in a warm place before using it, the first measurement won’t be relevant

because of big temperature variation.

Then loc the button (9) in the down secured position (10 b).

Then follow the procedure described in

5.2.3

CO2

C

ONTENT MEASUREMENT

10

5.1.3

D

ISCHARGING OF THE SAMPLE

Close the sampling valve on the tan , then open both inlet and outlet valves to remove any pressure

inside the hoses and the GMD. Then disconnect the inlet hose (3), place the outlet hose (5) to the

drain and turn the device upside down. At the same time hold the inlet hose (3) 10 cm over the

device. Chec visually if the transparent vessel (6) is empty.

If you are going to measure other samples, you don’t need to empty the GMD. You can rinse the old

sample with the new one by leaving the new beer flowing through the GMD about 30 s. If you are

finished with measurements, don’t forget to clean the device. Wipe device with a damp cloth.

5.1.4

C

LEANING OF THE DEVICE

Open the inlet valve (1) and the outlet valve (2). Place the outlet hose (5) to the drain. Connect the

inlet hose (3) to the potable water supply. Afterwards open slowly the water coc and rinse the

device with water. Both ball valves (1,2) have to be open during rinsing.

Warning! Pressure of water must not exceed value 250 Pa.

Whole internal space of the vessel (6) must be filled with water during cleaning. During rinsing pull

out and consequently press down several times the button (9) to rinse both pump and capillary.

It is important to remove any traces of beer to prevent the piston of the pump getting stuc .

After rinsing:

Once the cleaning is over, switch off the water coc . Disconnect the inlet hose (3) from the water

coc . If you plan to use the device next day, do not discharge the water from the device and pull up

the button (9) to suc the water inside the pump.

If you want to discharge the water then place the outlet hose (5) to the drain and turn the device

upside down. At the same time hold the inlet hose (3) 10 cm over the device. First open the outlet

valve (2) and subsequently open the inlet valve (1) and discharge the water. Chec visually if the

graduated vessel (6) is empty.

Clean the external surface with soft flannel moistened with water. After this handling the device is

ready for next measurement.

11

5.2

C

ONTROL OF THE ELECTRONICS

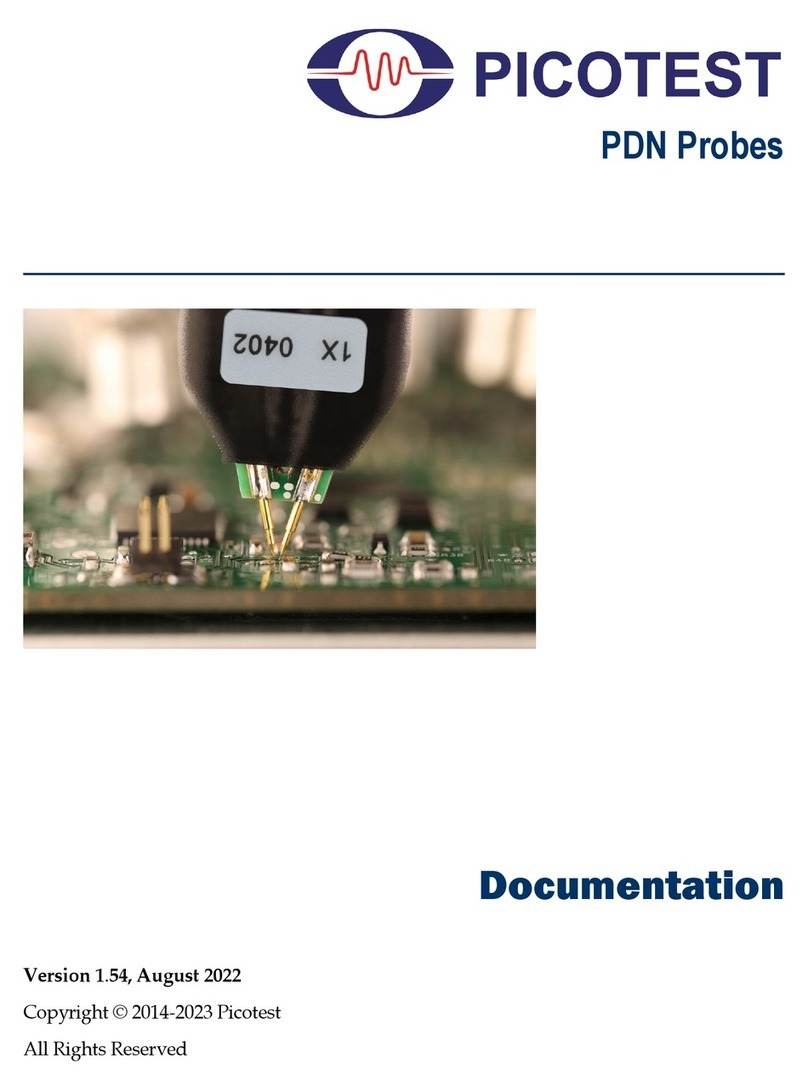

The device operation (i.e. switch-on, shutdown, measurement, …) is controlled with the help of the

membrane eyboard and the display.

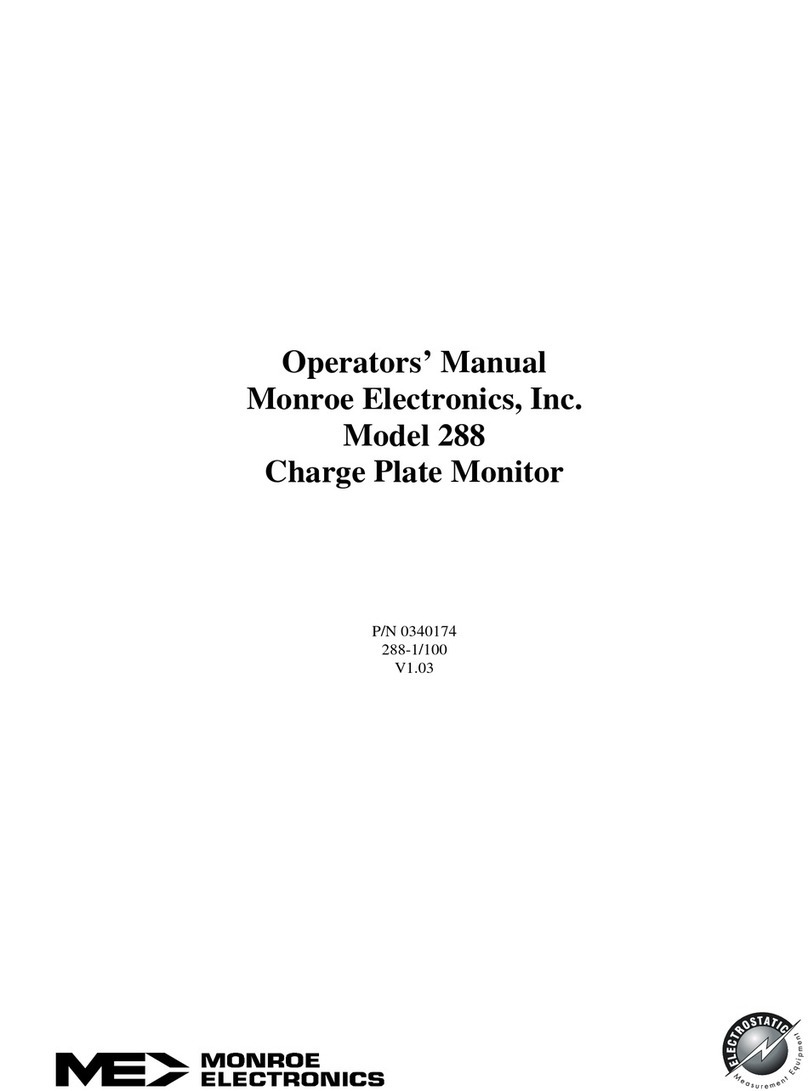

Pic.3.

Key Key Key Key Key Key Display

minus - plus + rotation OFF ON ENTER

5.2.1

S

WITCHING

ON

AND

OFF

THE DEVICE

Press the power button (12) to turn on and then press the ey ON to switch on the microcomputer.

Press the ey OFF to switch microcomputer off and then press the power button (12) to turn off.

5.2.2

C

HARGING OF THE DEVICE

If the battery voltage is too low then after the switch-on of the device, the text „Rech rge b ttery“

appears on the display for a second. It is possible to wor with the device for another 30 minutes. If

the device is not recharged during this time then the text „Low volt ge“ appears on the display and

the device is shut down. If you want to monitor how the battery is charged while wor ing with the

device – press the rotation ey - the text „b ttery“ appears on the first line of display and the

voltage of the battery on the second line. During charging of the device, the led BAT is lit.

Press the power button (12) to turn on and then unscrew the connector cover (13) and put the

opposite connector of the adaptor in to charge the device.

Warning: watch the right orientation (Bo of the adapter connector into the groove of the

ocket connector. The groove i marked with colored dot). AC/DC adaptor can be plugged into

the electric soc et now.

12

Note: In ca e the connector will not be put in the right way they will be damaged. Thi type

of damage i not covered by manufacturer’ warranty.

The device can be charged only with the supplied adaptor. Average charging time is about 8 hours

and the voltage of a charged accumulator is nearly 19V. „Rech rge b ttery“ is displayed under

16.5V and „Low volt ge“ under 15.5V The charging time can be shortened if needed but the

running period and the accumulator life-time will be shortened too. Once the charging of the device

is over, unplug the adaptor and the connector from the device. Then screw the cap of the connector

(13) for protection and press the power button (12) to turn off.

Notice: If the power button (12) is switched off during charging than the accumulator isn't

charging.

5.2.3

CO

2

C

ONTENT MEASUREMENT

Follow the paragraphs 5.1.1. and 5.1.2 and further:

1) Press the power button (12) to turn on and then press the ey ON to switch on the

microcomputer. The text „1-CUBE“ with the program version appears on the display for a moment.

Then the following text appears:

„ENT.mea .“ | „+ view.“

2) Press the ey ENTER. At the beginning of the measurement sequence, the pressure is measured

and displayed, until the pressure goes under the threshold value. This is achieved by opening

briefly the outlet valve (2). When the pressure is low enough, you will hear the buzzer of the GMD

and the display shows "close v.", which indicates that you have to close immediately the valve (2).

Now you can start releasing the CO

2

from the beer with the pump on the top of the GMD (loo

pic.2). Push out the button (9) of the secured position (10b) and pull it out into the upper position

(11). Hold it for a while in this position to equalize the pressure. Then press down the button (9) to

the very down unsecured position (10 a). After this handling dissolved CO

2

is fluttered and the

pressure increases in the chamber (6). Repeat this action one more time. Use it two times, not less,

not more, then be sure to secure the piston in the down position. Press the Enter ey and

„mea ure“ is displayed. The program waits a while for equilibrium, then the measured value of

pressure (e.g. 140kPa), followed by the measured value of temperature (e.g. 5.0 °C) appear on the

display.

Finally, the computed value of CO

2

content is shown e.g. 0.51 %bw | 5.1 g/l

By displaying CO

2

content the measurement of sample is over and the CO

2

value is saved in the

GMD(K) memory.

Press the ey ENTER to finish the measurement, the text:

„ENT.mea .“ | „+ view.“

The device is ready for next measurement. When the new sample has been ta en, you just need to

repeat this procedure to measure it. If it has been automatically shut off, switch it on as described

above. Press the power button (12) to turn off once the measurement is finished.

13

5.2.4

R

EADING RECORDED VALUES OF

CO

2

FROM MEMORY

The measured values of CO2 are ept into the device non-volatile memory. The capacity of memory

is 450 measured values.

1) Press the ey ON to switch on the device. The text „1-CUBE“ with the program version appears

on the display for a moment. Then the following text appears:

„ENT.mea .“ | „+ view.“

2) Press the ey plus (+). There is text „memory“ on the first line and the measured values of CO

2

in g/l appear in turn from the oldest value to the newest ones on the second line.

after the last saved value the numbers start to appear 655.35 which indicates blan memory

values. Press the ey ENTER to stop scanning memory. Then the following text appears

„ENT.mea .“ | „+ view.“

Note: Once memory is full, then it will be automatically deleted.

Then the following text appears:

„memory“ | „deleting“

All the saved values are overwritten with number 655.35.

5.2.5

D

ELETING THE CONTENT OF THE MEMORY

The measured values can be deleted from memory at any time. The memory capacity will be

completely recovered (450 values) and newly measured values will be saved in sequence.

1) Press the ey ON to switch on the device. The text „1-CUBE“ with the program version appears

on the display for a moment. Then the following text appears:

„ENT.mea .“ | „+ view.“

2) Press the ey minus (-).Then the following text appears: „memory“ | „deleting“

All the saved values are overwritten with number 655.35.

6.0

CO2

TRANSFERRING MEASURED VALUES FROM MEMORY TO

PC

COMPUTER

(

TYPE

GMDK

ONLY

)

Only type GMDK has the functionality of data transfer with a communication cable to PC. Before the

first data transfer from the device to the PC, first install program DataViewer from our supplied

CD.

1) Connect the shut-off device GMDK with the help of cable FTDI USB-RS485-WE-1800-BT

(supplied with the device version GMDK) with USB port of your PC. Wait until the driver is fully

installed and ready. This occurs the first time you plug the USB adapter into a USB port of your

computer.

14

2) Run the program DataViewer in your PC and select the corresponding COM port (e.g. COM 5). If

you don’t now which COM port is affected to the USB adapter, you can find it easily by plugging

the USB adapter, then launch the DataViewer program and open the list box under Com port select.

Loo at the entries. Then close the program, unplug the USB adapter and re-open the software. The

missing entry in the list box corresponds to the COM port affected to the USB Adapter. The program

will memorize the selection and you will not have to select it again the next time.

3) Press the ey ON to switch on the device GMDK. The text „1-CUBE“ with the program version

appears on the display for a moment.

4) Press the ey plus (+).There is text „memory“ on the first line and the measured values of

CO

2

in g/l appear in turn from the oldest to the newest ones on the second line. At the same time

these values are displayed in DataViewer program window in column in turn from the oldest value

to the newest ones and also plotted on the graph. These values can be saved into file with the Save

file button.

Note: the measured values are displayed in g/l in DataViewer program.

7.0

S

ERVICE

For service contact the manufacturer: 1-CUBE

Hamry 3567

580 01 Havlíč ův Brod

Czech Republic

tel. +420 569 433 620

fax. +420 569 422 144

Plea e vi it our web ite for late t new and product : http://www.1-cube.com

NOTICE: It is forbidden for anyone except for the manufacturer or authorized company to repair

the apparatus.

At the end of the apparatus life we recommend that it is according to corresponding waste

categorization.

Ta e the metallic parts made of iron, brass, plastic elements and pac ing material to the separated

collection as a secondary raw material. You can also order the apparatus liquidation at the above

mentioned company that ensures the liquidation of the waste according to Waste Act.

This manual suits for next models

1

Table of contents

Other 1-CUBE Measuring Instrument manuals