Line voltage adjustment: Rotate the

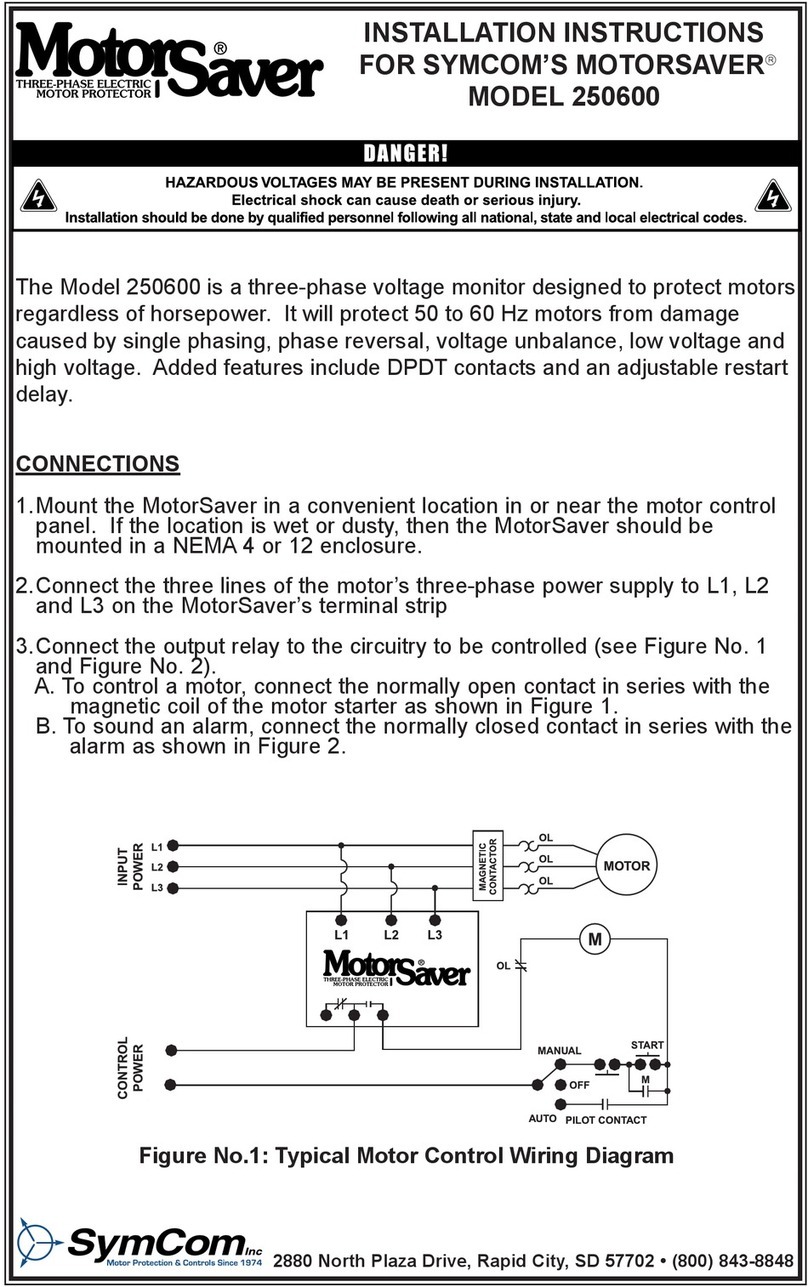

three-phase line voltage feeding the motor

2. Restart delay adjustment: Rotate the

desired position. The restart delay is the

acceptable voltage and the MotorSaver

closing its output contacts. For

compressor applications, the restart delay

should be set for the approximate time it

takes for the head pressure to bleed

off of the compressor. For other

applications, the restart delay is typically

set between 2 and 10 seconds.

3. Trip delay adjustment: Rotate the

adjustment to the desired

setting. This adjustment does not affect the

trip delay on phasing faults. Typically, the

trip delay adjustment is set between 1 and 5

seconds. In areas where voltage uctuations are frequent, the trip delay

adjustment may be set greater than 10 seconds.

4. Voltage unbalance adjustment: Rotate the

adjustment to the desired unbalance trip level. The NEMA MG1 standard

does not recommend operating a motor above 1% voltage unbalance without

the motor. The NEMA MG1 standard also recommends against

operating a motor above a 5% voltage unbalance under any circumstances.

SymCom recommends consulting the motor manufacturer for speci c

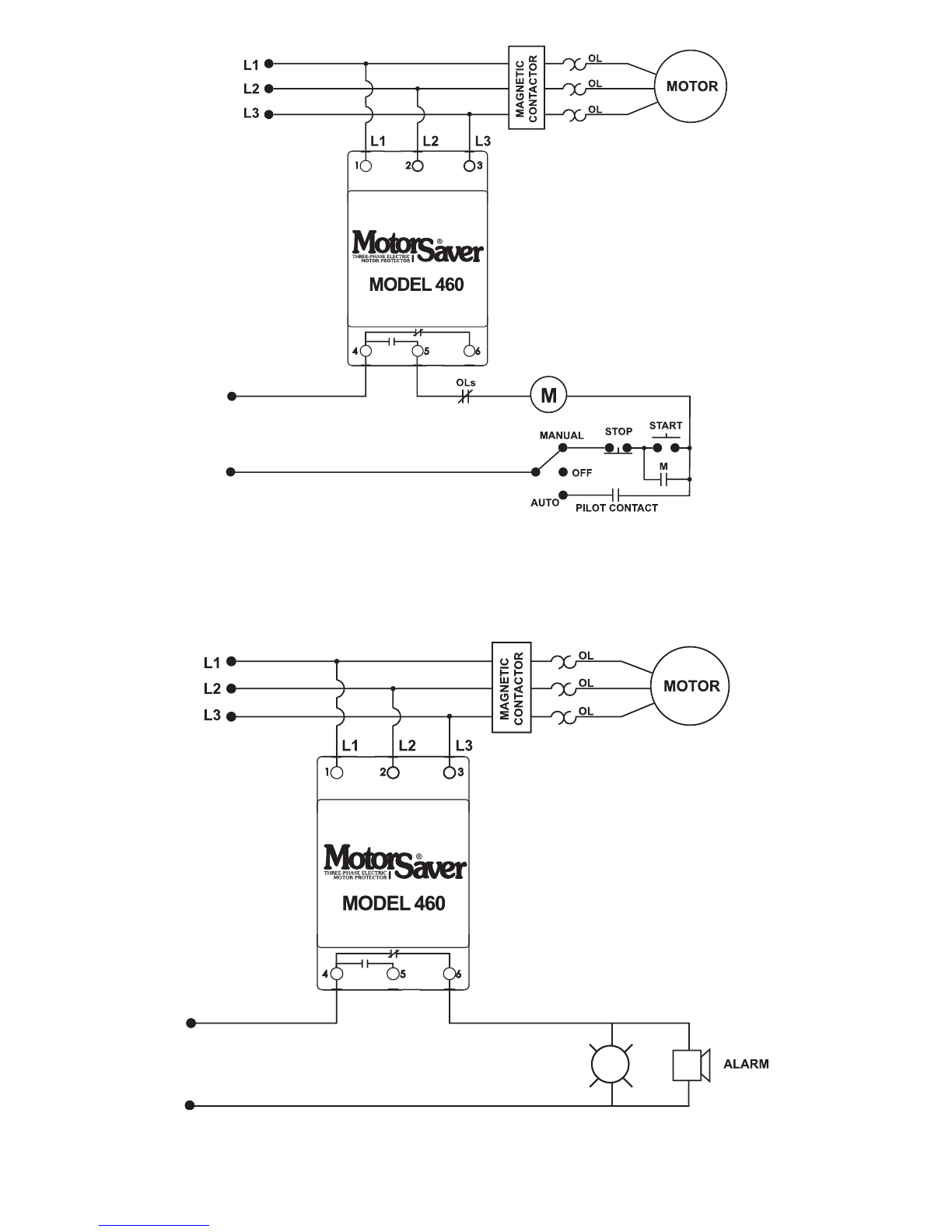

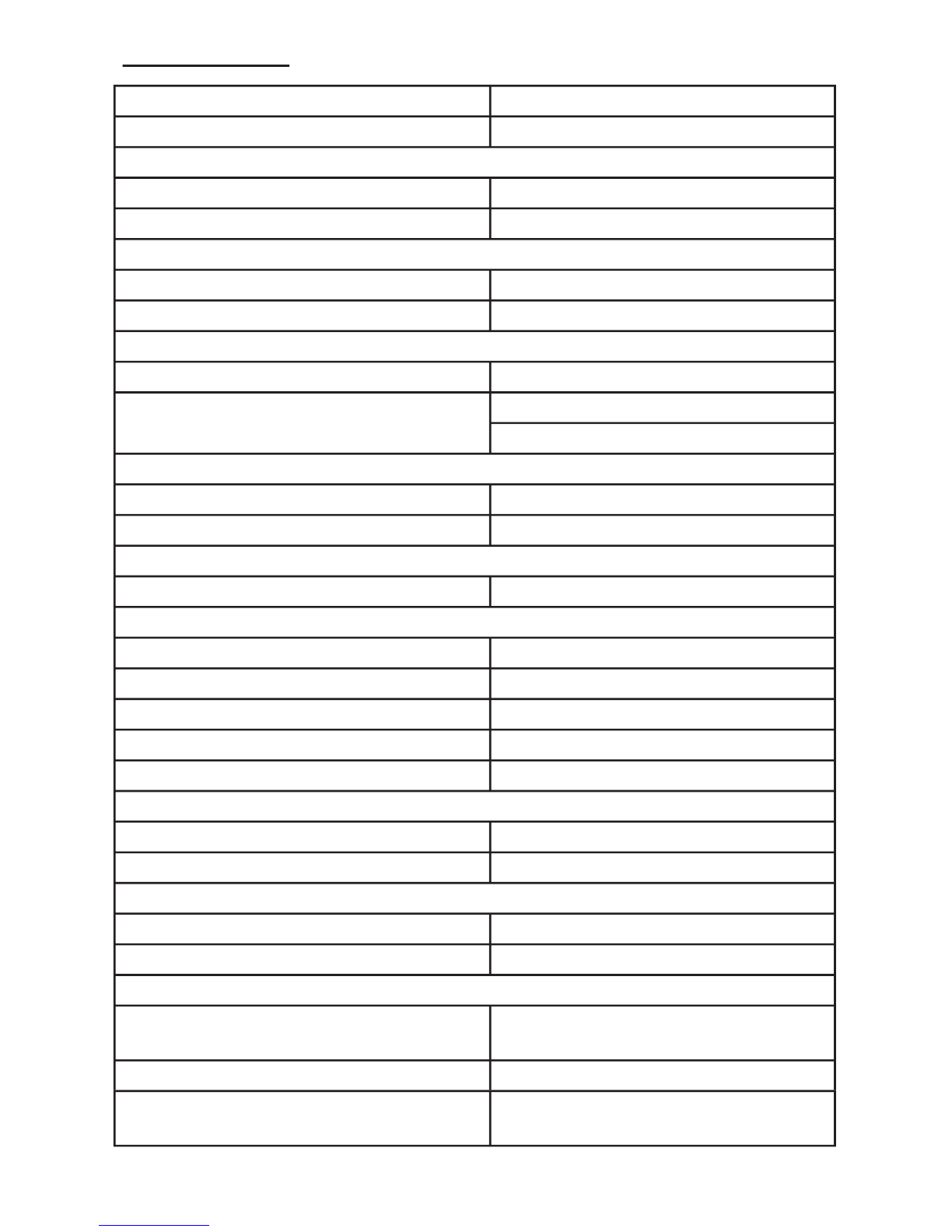

MODEL 460

190

200

416 440

230

240

380 480

400 460

208 220

Percent Unbalance = Maximum Deviation from the Average

Average x 100

Example: The measured line-to-line voltages are 203, 210, and 212.

Average = 203 + 210 + 212

3= 208.3

The maximum deviation from the average is the largest difference

between the average voltage (208.3) and any one voltage reading.

208.3 - 203 = 5.3 210 - 208.3 = 1.7 212 - 208.3 = 3.7

The maximum deviation from the average is 5.3.

5.3

208.3 x 100 = 2.5% Unbalance

Phone:

800.894.0412

-

Fax:

888.723.4773

-

Web:

www.clrwtr.com

-

Email:

[email protected]