slightly warp the fuselage to get the desired fit of the tabs and that is exactly what we

want. Now cut out part #24. Look carefully and you will find a short gray line that runs

lengthwise on the center of the piece. This is where the antenna mast will be mounted

later. While the piece is still flat you need to cut a slot where the line lies now. See figure

5. Now you are ready to mount part #24 to the fuselage. Remember to check the fit

before applying glue to insure proper placement. When the top part of the fuselage is

complete it should not be flat. It should be raised in the center along the full length of the

fuselage see figure 6. If you can draw the sides down like shown in figure 3 the top

should be evenly curved along the length of the entire piece with no wrinkles. Cut out

part #23 the antenna mast. Fold this piece in half and glue the mast portions together. The

mounting tabs are to be folded out at a 90-degree angle. Apply glue to the top of the tabs

and thread the mast through the slot in part #24 from the inside out.

OK, now that we are done with the top of the fuselage lets start on the bottom. First let

me give you a word of warning. This is one of the more difficult

assemblies of the kit so be sure to fit everything up before you glue.

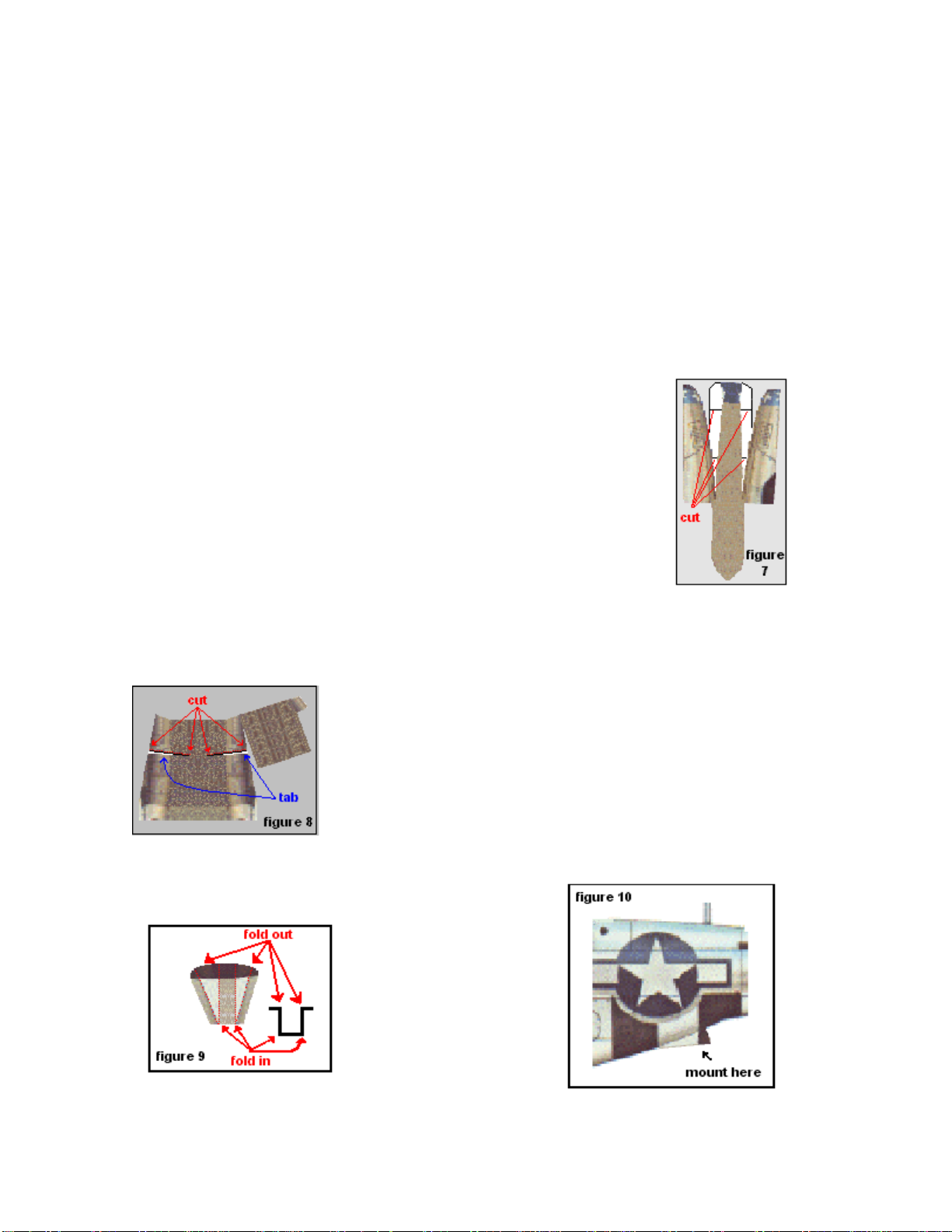

Find part #22 and cut it out remembering to leave the white areas

that are bordered by a black line attached. Make cuts along the four

black lines that run in from the edges of the white tabs. The white

tabs are intended to remain attached to the piece that resembles a

necktie and cut away from the two sidepieces. Don’t cut the two

sidepieces completely off. There should be a very small area left that

connects them to the center section. See figure 7. Apply glue to the

white tabs and glue them to the backside of the sidepieces. Attach

each section of tab one at a time starting from the bottom working up

to the top. Take care to cover the white area only. The warping of the parts becomes

increased with each tab. This creates the shape needed to form the bottom of the nose

section. This piece needs to be aligned accurately. Use the color scheme of the aircraft to

mount part #22 to the nose section of the fuselage.

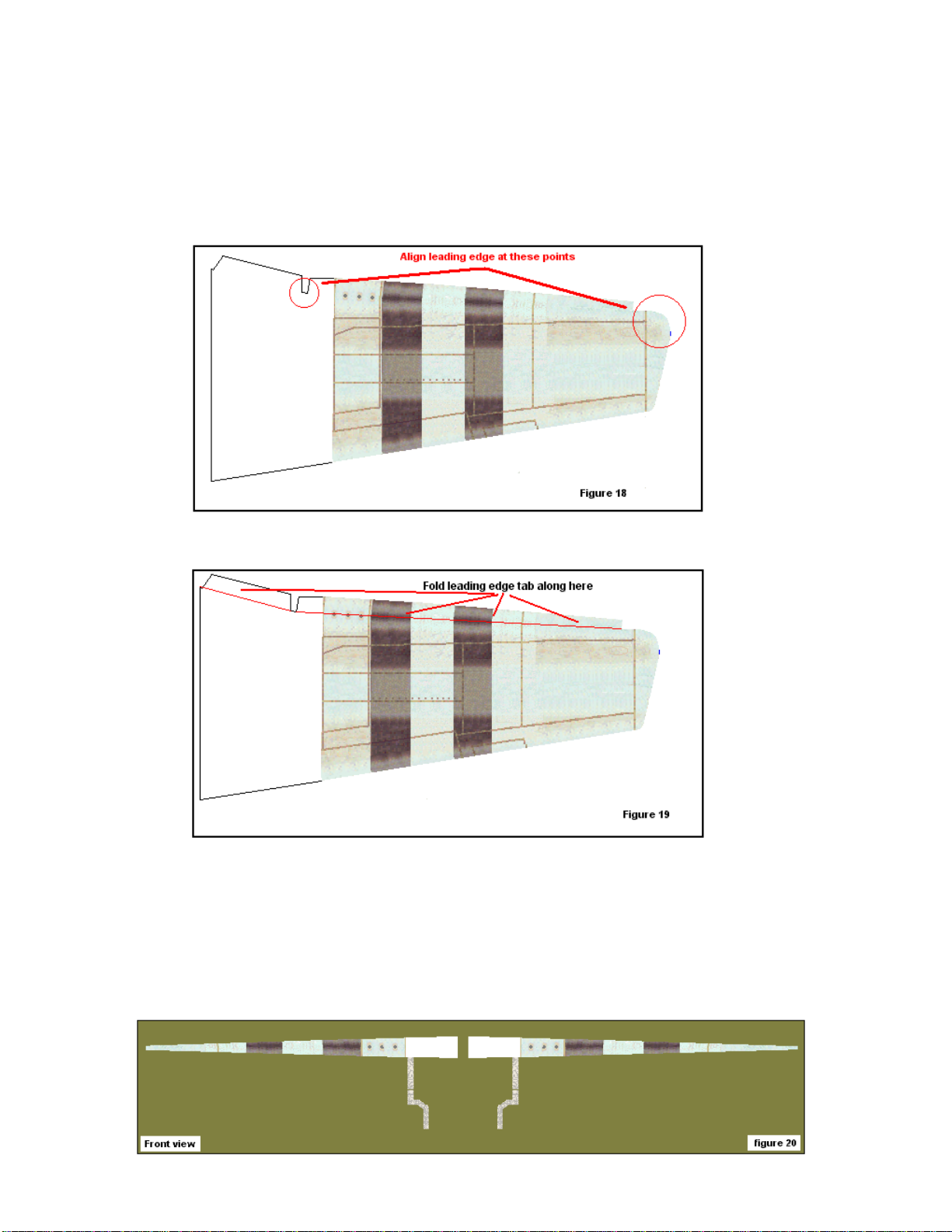

Locate part #25 and cut it out. Like part #22 the white tabs are

to remain attached to the center section of the piece. Two cuts

are to be made on the scoop area. Make those cuts on the color

side of the black line. The white area is not to be removed.

Although they are extremely small they are gluing tabs.

Draw the pieces together just enough to cover the small white

tabs and glue into place. Glue the sides to the center section in the same manor as part

#22. Next shape the piece so that the bottom is flat with the sides bent upward (NO

CREASE) at a 90-degree angle to the bottom. Now

fold the top of the air scoop over and glue the tab to

the opposite side. Glue the

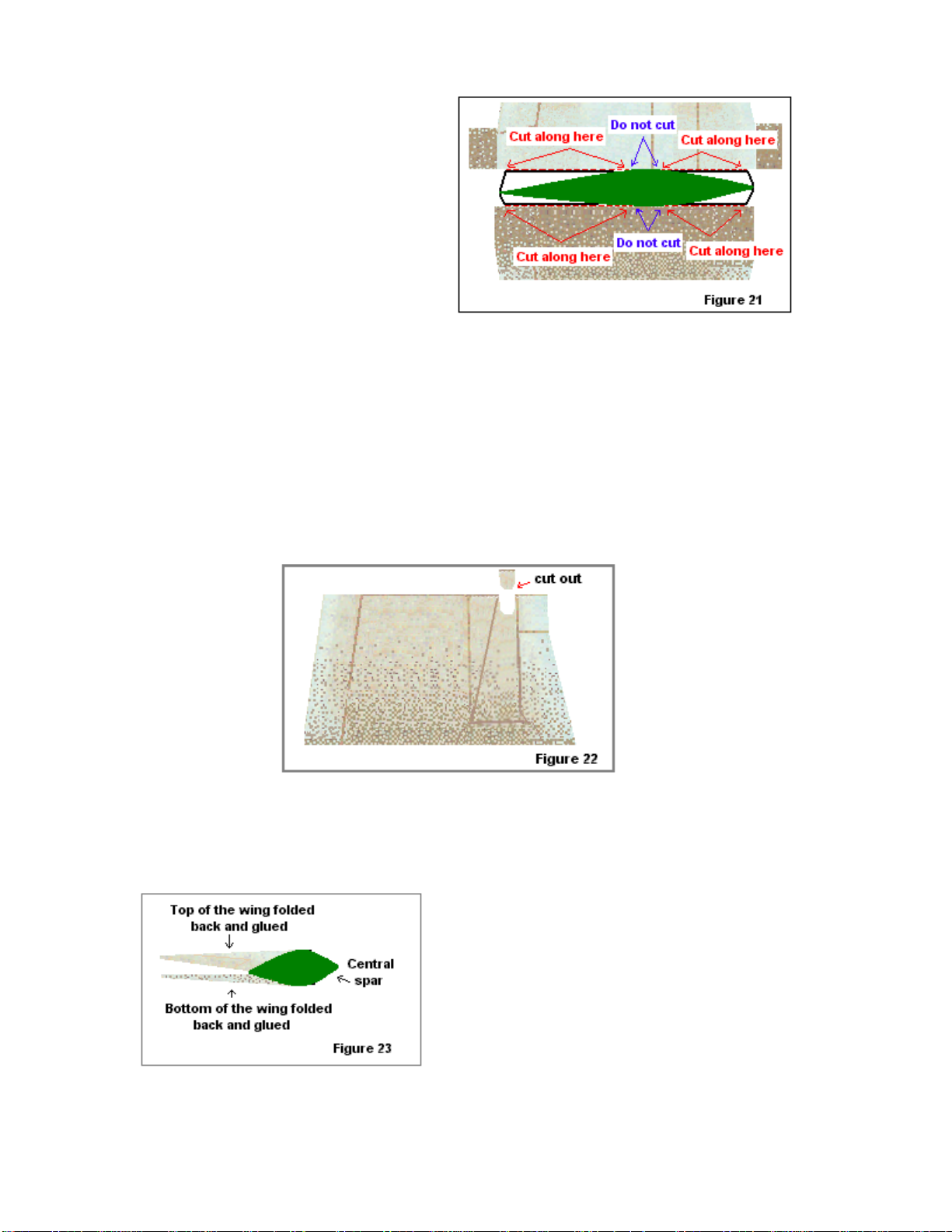

completed part to the

fuselage just aft of the

wing mount once again

using the color scheme to

determine the proper

alignment. I have found

that by lining up on the stars first everything else will

fall into place. A pen is useful when applying this part. Insert it in the fuselage and use it

for something to push against when pressing the piece in place.