Building Techniques

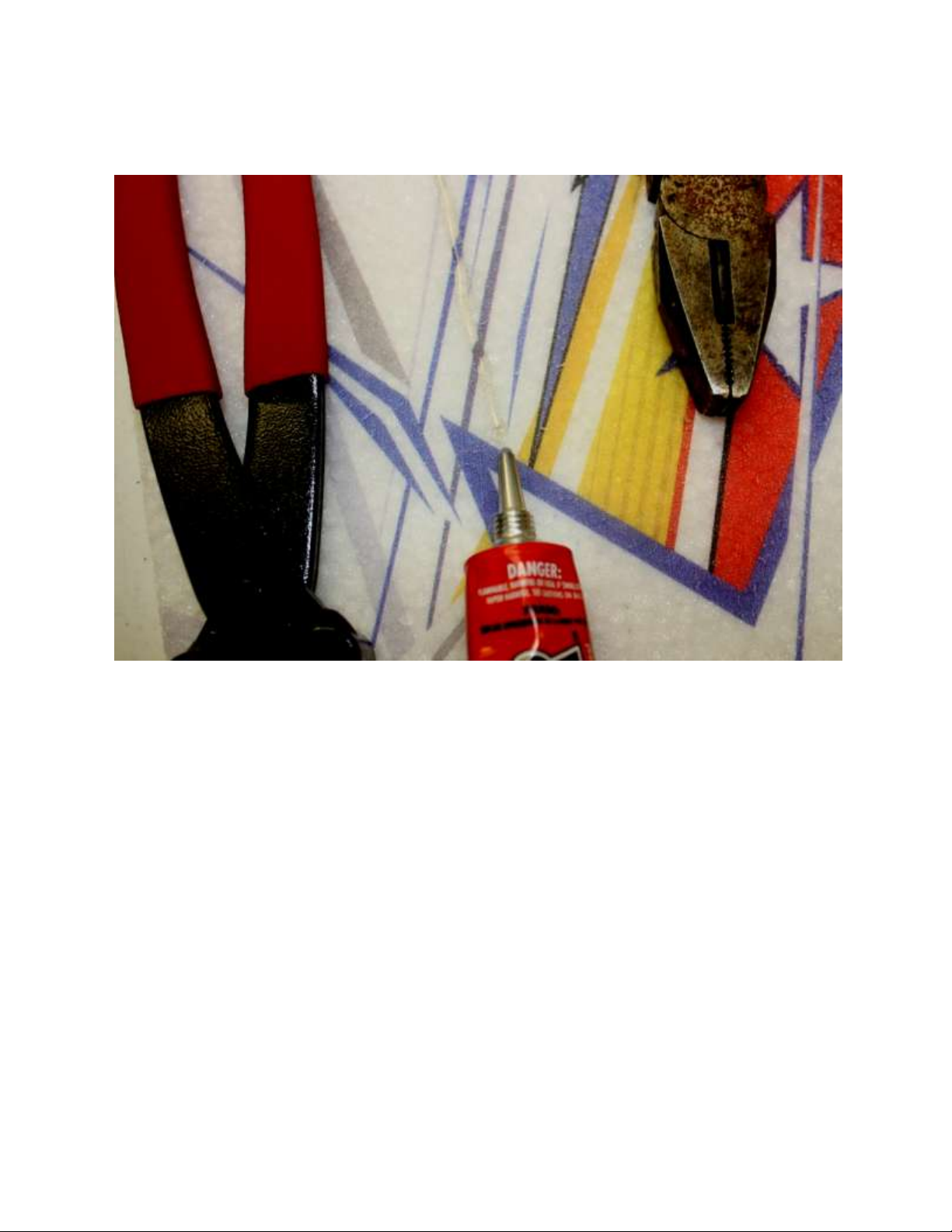

The 38” Slick uses specific building techniques for EPP foam. Most glues and tapes will not

adhere well to EPP foam. We recommend a glue called “Welder” made by Homax Products Inc,

it is Homax part #730657. We carry this glue at www.3dhobbyshop.com and attempt to keep it

in stock at all times. If you need an alternate source, it is available from

www.homaxproducts.com, at most Lowe’s home improvement stores, and at the time of this

writing, a quick search of the internet revealed at least 20 additional online sources. Correct

assembly of the 38” Slick kit requires approximately 1.5 tubes of welder glue.

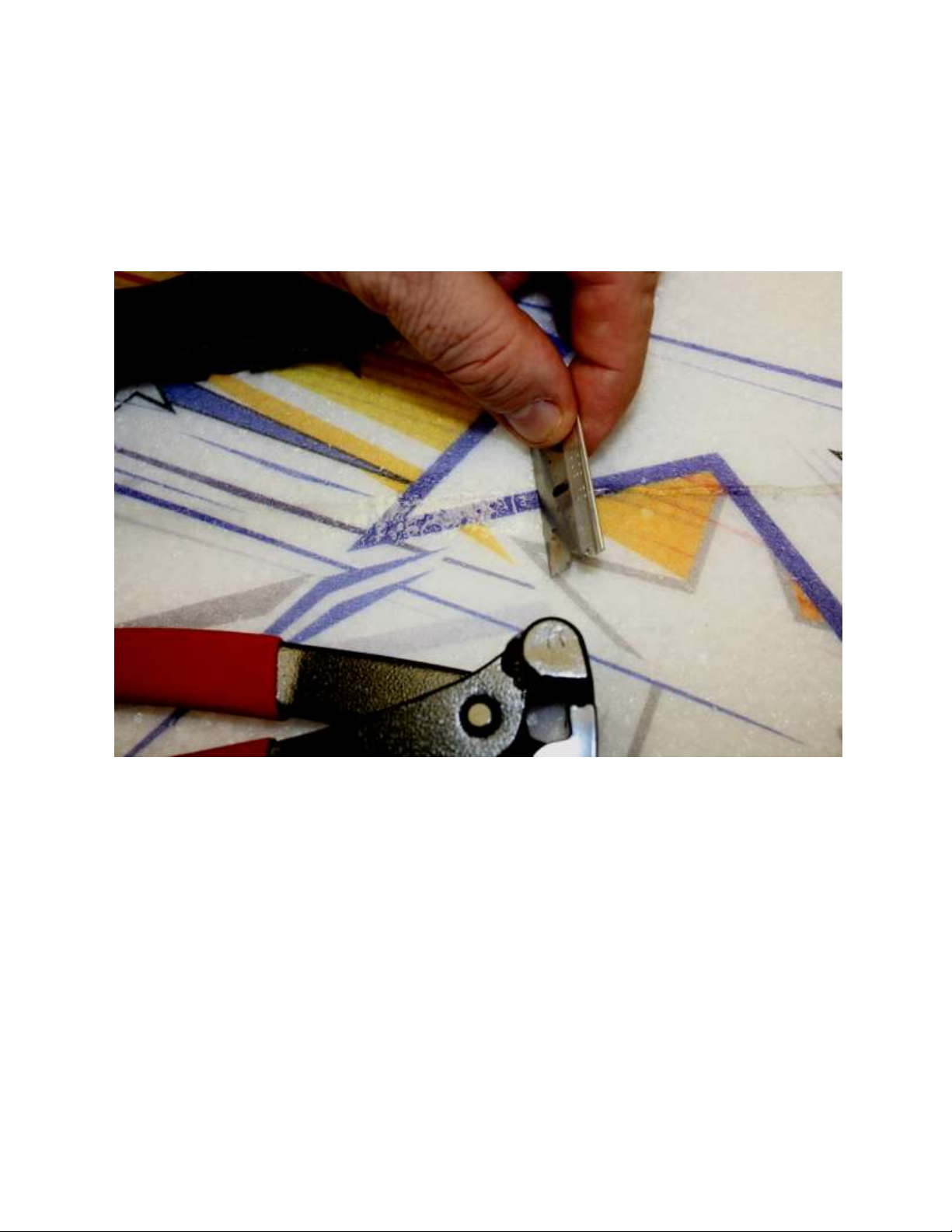

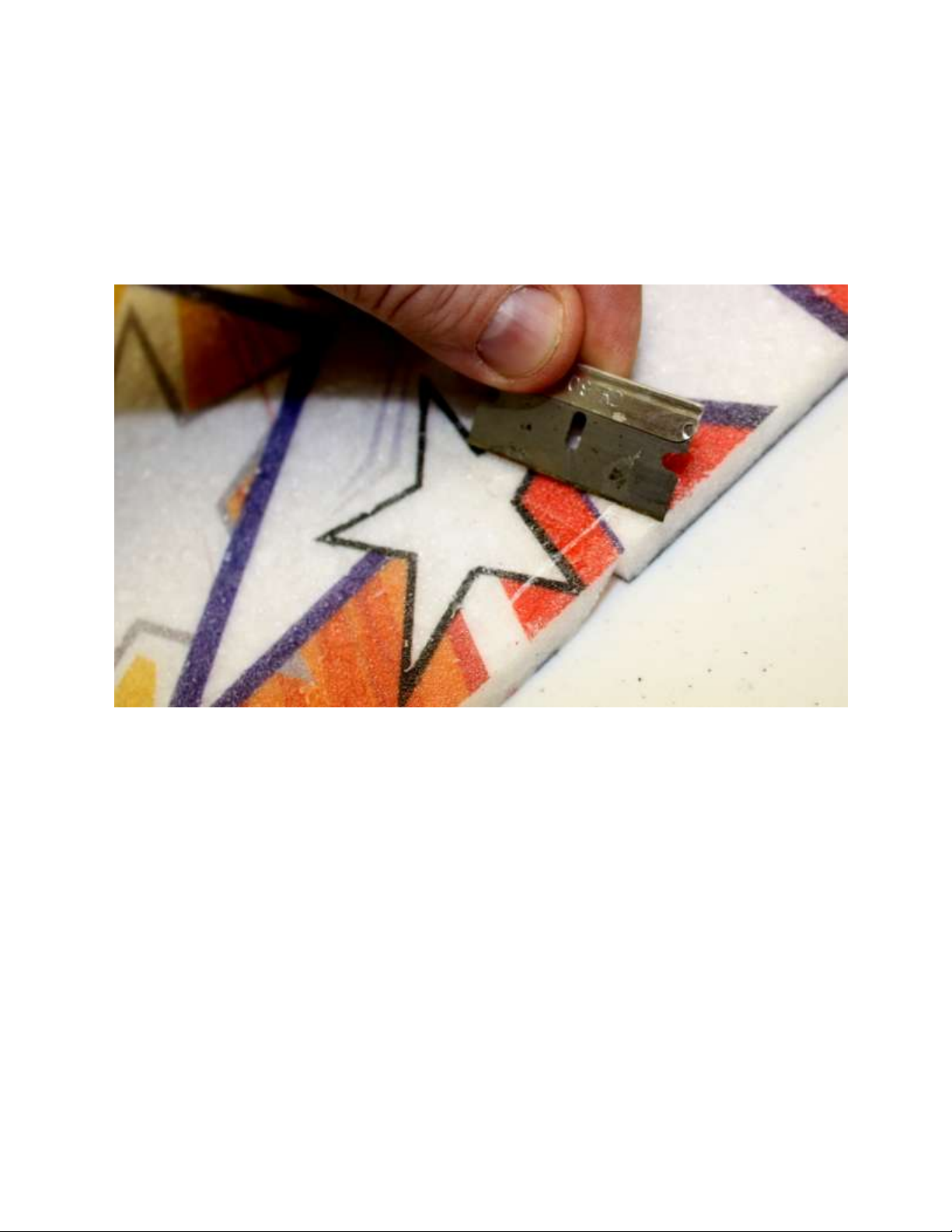

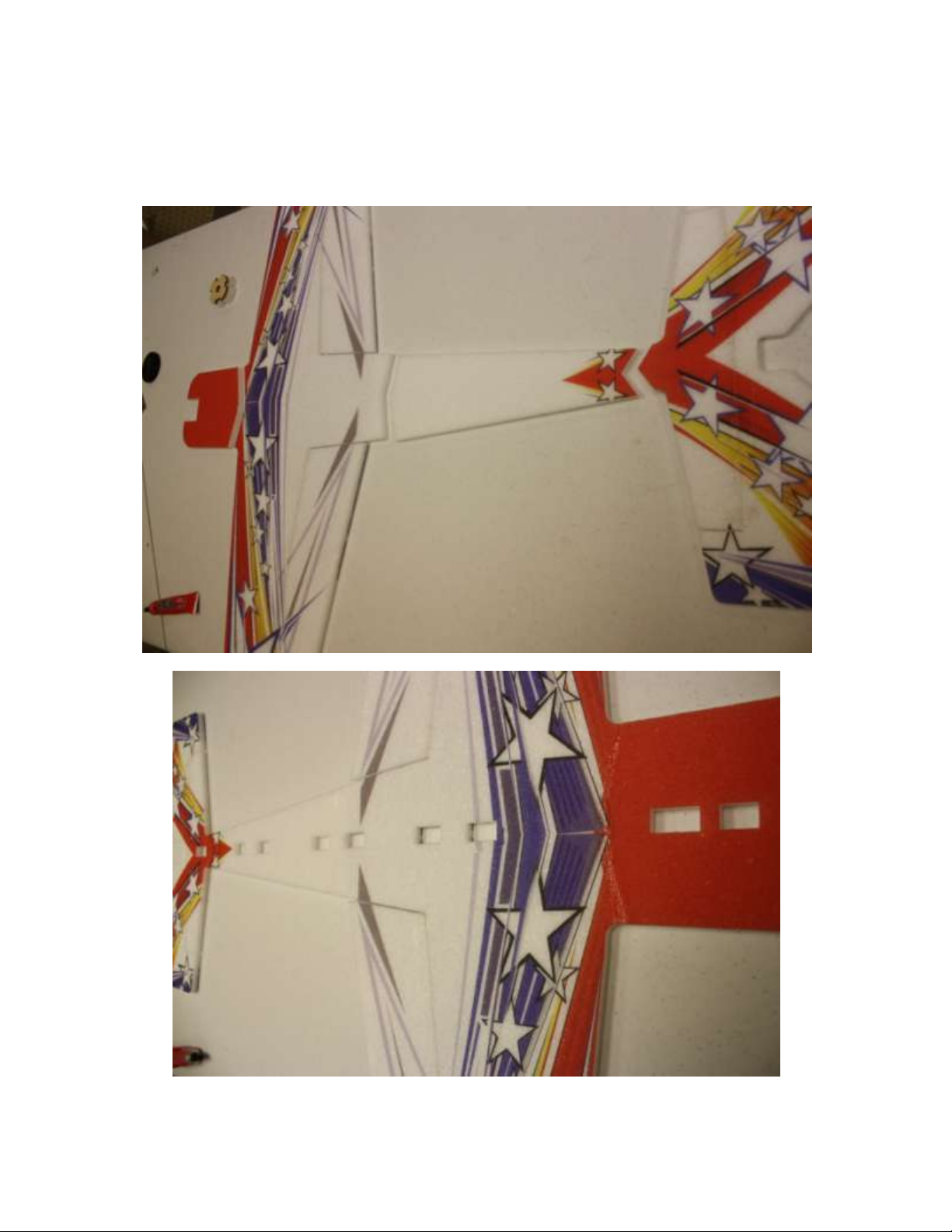

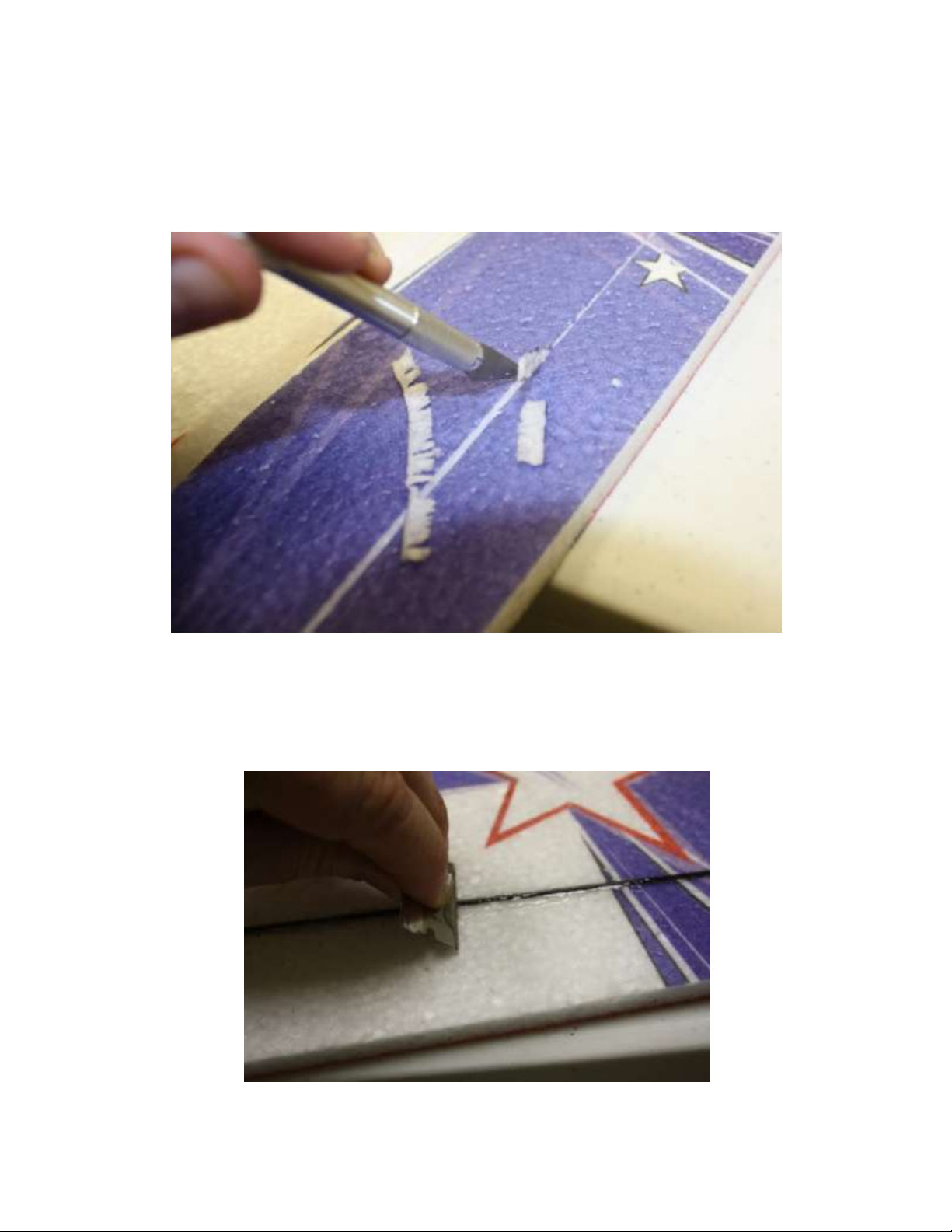

The Welder glue will be used to assemble the EPP foam pieces, and also to create the hinges on

this aircraft. Welder glue, when dry, is tough and flexible and makes an excellent hinge

material. If you are not familiar with the technique of making glue hinges on EPP foam aircraft,

a video may be most helpful to explain this technique. We have produced an instructional

video series covering the build of our 33” EPP Extra. The 33” Extra and the 38” Slick are built

using similar techniques. We highly recommend that you watch the 33” Extra instructional

videos before building your Slick if you are unfamiliar with these techniques.

The 33” Extra videos are hosted on www.youtube.com The exact address of the video on

hinging is: http://www.youtube.com/watch?v=RNpTN5S-wdc although it is easier to simply

navigate to the www.youtbe.com and type “3DHS EPP Build videos” into the search bar. There

are seven parts to the build video.

You will also be cutting pieces of carbon fiber rod and bar stock for this build. The best way to

cut carbon fiber is with a dremel or other rotary tool, with proper eye and skin protection.

However, you can cut carbon rod by rolling the rod under the blade of hobby knife on a hard

surface. Be careful when handling carbon fiber after you have cut it to avoid splinters, and

always wear proper eye protection.

Finally, you will be making Z-bends on steel music wire in this build. We show in the manual

and aforementioned videos how to make them with needle-nose pliers, but a set of “Z-bend

pliers” such as Hangar9 part #HAN119 makes this job much quicker and simpler.