6

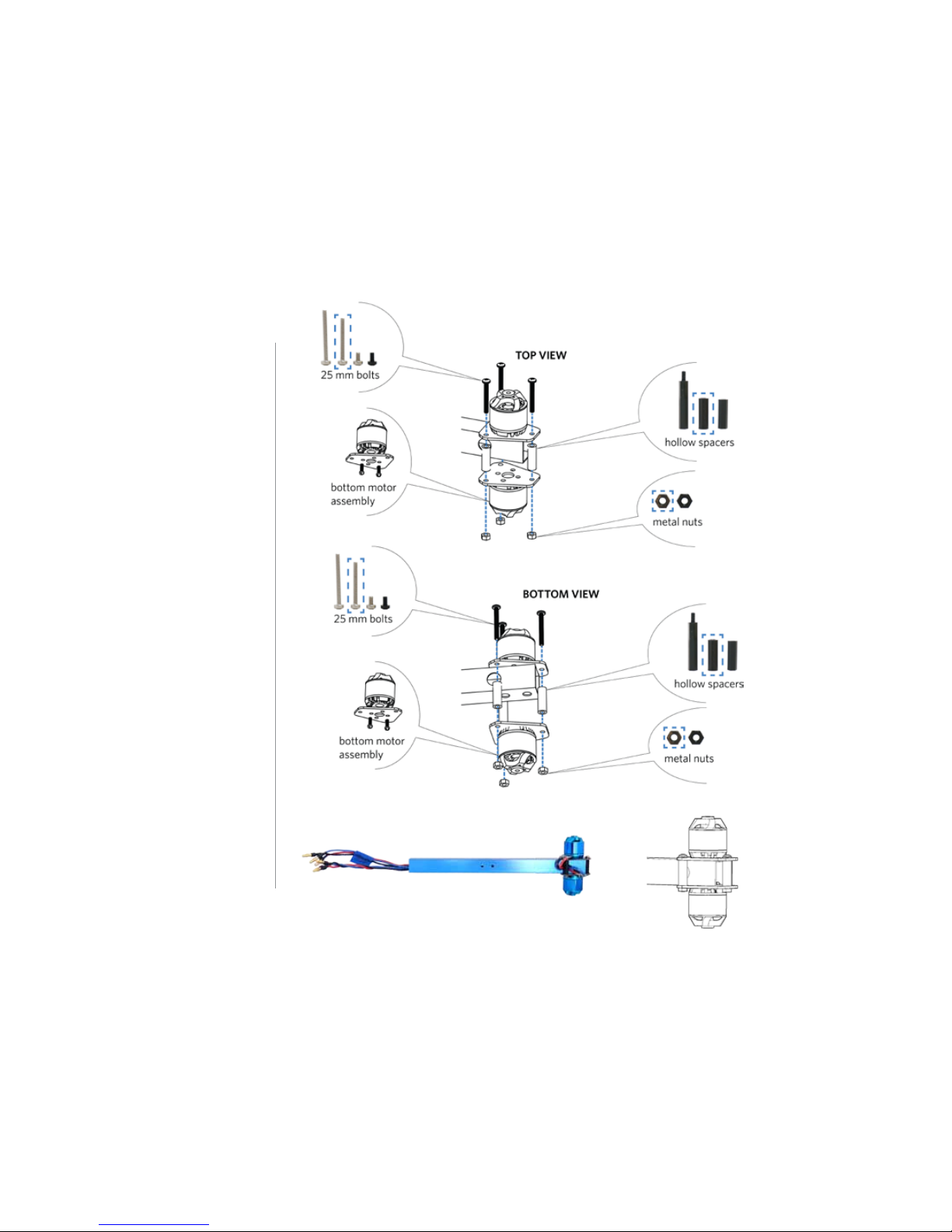

2 Attach top motor to arm

Place a motor plate on top of the arm

with the short end of the plate facing

towards the end of the arm. Place the

motor on top of the plate, and align

the two small holes in the motor,

plate, and arm. Orient the motor with

the cables as close as possible to the

hole in the side of the arm.

Apply threadlocker to two 5 mm

bolts (less than one drop covering

four or five threads at the end of the

bolt), and secure the motor and

plate to the arm from below by

accessing through the two large holes

in the bottom of the arm. Make sure

to insert the bolts into the holes in

the bottom of the motor and not into

the slots where they could interfere

with the motor.

3 Thread motor cables through arm

Now you’ll thread the cables from

both motors through the arm. First,

thread the cables from the top motor

through the hole in the side of the

arm, and use a piece of tape to label

the cables so that you can distinguish

between the top and bottom

motor cables. Once you’ve labelled

the top motor cables, thread the

bottom motor cables through the

hole in the arm.