7

TECHNICAL MANUAL ICM 3L.P. GAS s.r.l.

3.0 ACCESSORIES

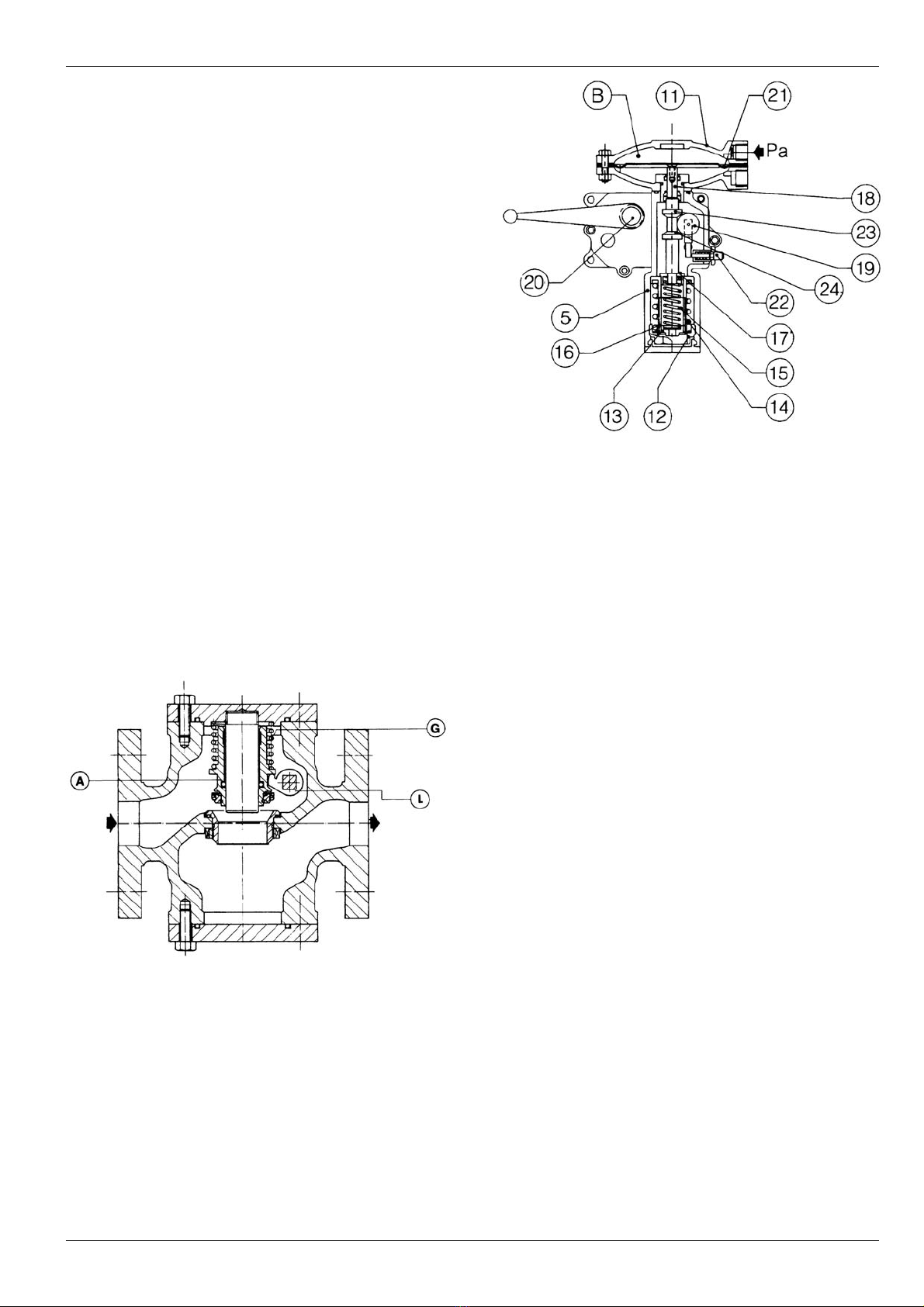

3.1 “PUSH” THREE-WAYS SWITCH VALVE

(FIG. 8)

The “Push” is a special spring three-ways switch val-

ve. When the knob is in the “rest” position, the angular

A and B ways are in comunication while the C way is

excluded. With the knob pressed down in the “check”

position, the A and C way are connected and the B

way excluded. When thrust is taken off the knob, the

connection between A and C is AUTOMATICALLY

REESTABLISHED by means of the spring pos. 11.

With the steam in the middle “open” position, the three

ways are all in communication with each other. This

cock is normally installed in the impulse lines of safety

devices for protection against pressure increases and/

or decreases (SAV and SBV) in order to allow very

rapid verification of the settings without disconnec-

ting the impulse pipes themselves during periodical

checking operations. Its particular feature lies in the

fact that, during normal running, the head (or the pilot

of safety valve) receives the signal of the pressure to

be kept under control through the A and B ways; when

testing, the head receives the signal of a CONTROL-

LED PRESSURE from the A and C ways; once the

check has been carried out, when the knob returns to

the “rest” position, the connection is automatically re-

established between the safety device head and the

environment with the pressure to be controlled, thus

avoiding the risk to shut off the safety device itself as

it would in the case of a normal, manually-operated

threeway cock, due to a trivial oversight. In other

words, the “Push” is a SECOND SAFETY DEVICE

which ensures the NON EXCLUSION of the main

safety device and allows for its “Fool-proof”

PERIODICAL CHECKING.

The stem is fitted with a stroke limit pin which makes

it possible to:

- connect A and C ways only when the pin enters the

“check” slot;

- connect the three ways, a, B and C, when the pin is

on “open”.

4.0 START UP

4.1 GENERAL

After installation, check that the inlet/outlet on/off

valves, any by-pass and the bleed cock are closed.

Before commissioning, you must ensure that the

conditions of use comply with the characteristics of

the apparatuses.

These characteristics are recalled by the symbols on

the specification plates applied to each apparatus.

We recommend actuating the opening and closing

valves very slowly. The valve could be damaged by

operations which are too fast.

APPARATUS SPECIFICATION PLATES

The list of symbols used and their meanings are listed

below:

Pemax = maximum operating pressure at the inlet of

the apparatus

Pzul = maximum pressure which can be supported by

the structure of the body of the apparatus in safety

conditions

AG = intervention accuracy

Wao = range of intervention for the over pressure of

slam-shut, relief and safety valves and accelerators

which can be obtained using the setting spring fitted

at the moment of testing. In piloted safety valves, the

pilot is considered as a separate apparatus with its

own setting range Wao

Who = range of intervention for the over pressure of

slam-shut, relief and safety valves and accelerators

which can be obtained using the setting springs

indicated i the tables. In piloted safety valves, the pilot

is considered as a separate apparatus with its own

setting range Who

Wau = range of intervention for pressure decrease of

sla-shut which can be obtained using the setting

springs indicated in the tables.

Fig. 8