3

Parts Page

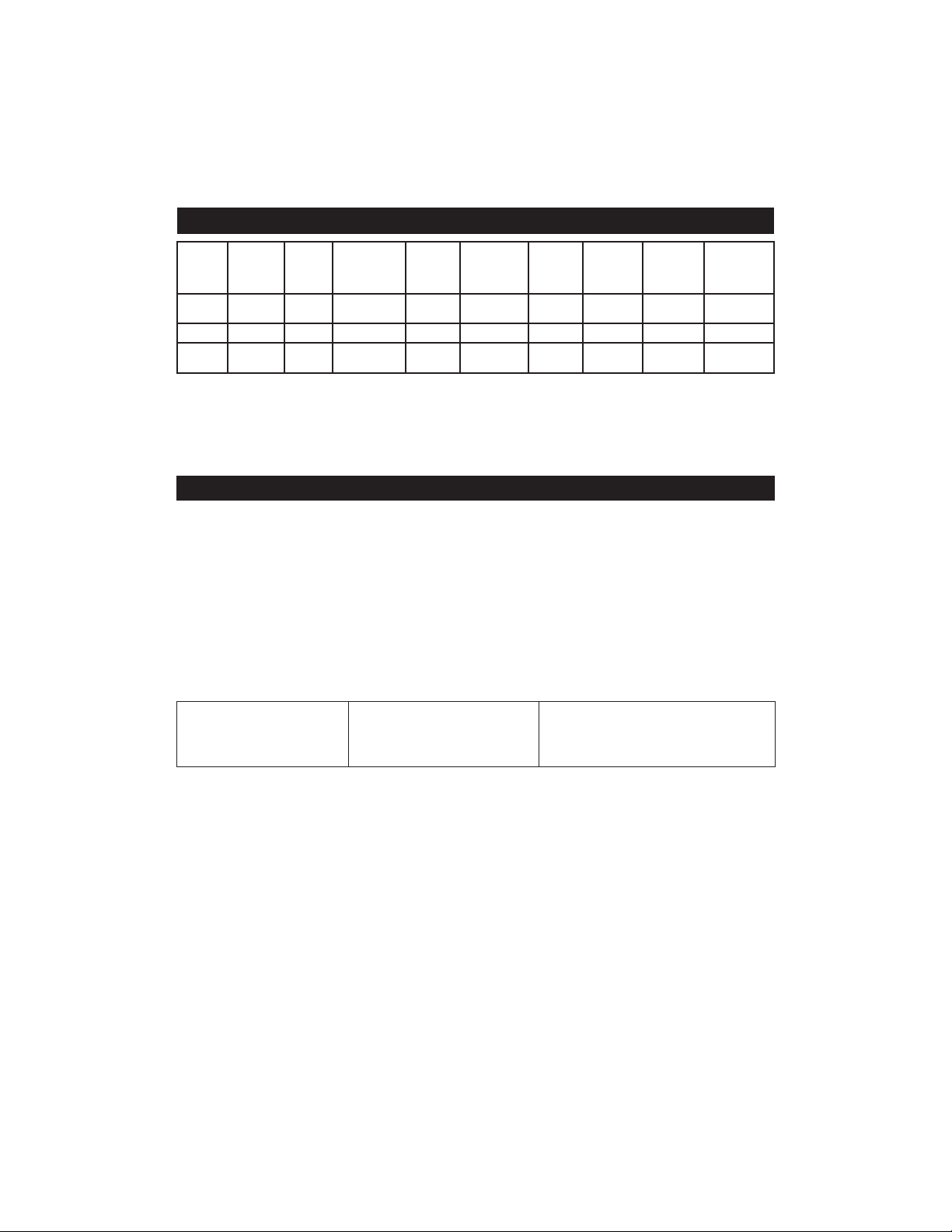

Fig. 3M PN Description Qty

1 54069 Flange Nut, 5/8-11 2

1 54068 Flange Nut, M14-2 2

2 54062 Guard Assembly, Standard 4 1/2" 1

2 54063 Guard Assembly, Jumbo 4 1/2" OPT

2 54065 Guard Assembly, Standard 5" OPT

2 54066 Guard Assembly, Jumbo 5" OPT

3 54061 Autobalancer 1

4 54059 Retaining Ring 38 mm x 6 mm 1

5 54058 Felt Ring 32 mm x 4 mm 1

6 54057 Spindle 5/8-11 1

6 54056 Spindle M14-2 1

7 54055 Bearing, Main Spindle 1

8 54054 Gear Set 1

9 54060 Wick, Gear Oil 1

10 54053 Bearing, Top Spindle 1

11 54052 Circlip 1

12 54051 Oiler Screw 1

13 54081 O Ring 5.6 mm x 1 mm 2

14 54049 Handle Insert 1

15 54048 Side Handle, 2.5" x 6", M10-1.5 1

16 54070 Spindle Lock Assembly 1

17 54050 Angle Head Housing 1

18 54089 Bearing, Motor 2

19 54090 Housing, Front Motor Bearing 1

20 54091 Cylinder, Motor 1

21 54092 Spacer, Rotor 1

22 54104 Key, Square 3 mm x 3 mm x 8 mm 1

23 54094 Rotor 1

24 54093 Rotor Vane Set of 4 1

25 54095 Housing, Rear Motor Bearing 1

26 54097 Governor 12K RPM 1

26 54096 Governor 8K RPM 1

27 54071 Connector, Angle Head 1

28 54100 O Ring, 44 mm x 2 mm 1

Fig. 3M PN Description Qty

29 54072 Air Inlet Tube 1

30 54073 Lock Ring 1

31 54074 Cover, Rear Handle Housing 1

32 54075 Housing, Rear Handle 1

33 54080 Valve Stem,Throttle 1

34 54082 O Ring, 11 mm x 1.6 mm 1

35 54083 Insert, Throttle 1

36 06642 Safety Lever Assembly 1

37 54079 Pin, Safety Lever 1

38 54076 Throttle Insert 1

39 54103 O Ring, 20.5 mm x 2 mm 1

40 54077 Ball, Air Inlet 1

41 54078 Spring, Air Inlet 1

42 54102 Bushing, Air Inlet 1

43 54101 Filter, Air Inlet 1

44 54099 Screw, Exhaust M5 x 6 mm 2

45 54088 Cover, Exhaust 1

46 54098 Gasket, Exhaust 1

47 54087 Bafe, Exhaust 1

48 54086 Spring, Exhaust 2

49 54085 Piston, Exhaust 2

50 54084 Housing, Exhaust 2

51 54105 Wrench, Spanner, 4 mm x 30 mm B. C. 1

-- 54107 Rebuild Kit OPT

-- 54106 Tool Kit, Rebuild OPT

-- 28828 3M™ Air Tool Lubricant, 1 oz OPT

-- 20451 3M™ Air Tool Lubricant, 4 oz OPT

-- 20466 3M™ Air Tool and Compressor

Lubricant, Quart

OPT

-- 20467 3M™ Air Tool and Compressor

Lubricant, Gallon

OPT

-- 28827 3M™ Gear Oil, 4 oz OPT

Notes: FOR EQUIVALENT PARTS OF ALL TOOLS IN THESE INSTRUCTIONS:

1. Items denoted by X in exploded view and highlighted gray in parts list are

included in Rebuild Kit PN 54107.

2. Items listed as OPT available separately.

3. Apply one drop, 3M™ Scotch-Weld™ thread locker (or equivalent thread

locking compound), type as noted, where indicated.

4. Saturate Wick (item 9), with 3M™ Gear Oil PN 28827 (or equivalent 68

centistoke oil) prior to assembly.

5. Bafe (item 47), can be cleaned and reused by soaking in solvent and blowing

dry with compressed air.

6. Lightly coat Vanes (item 24) and Cylinder (item 20) inner diameter with 3M™

Air Tool Lubricant PN 20451 (or equivalent 10 centistoke oil) prior to assembly.

7. Handle Insert (item 14) and Spindle Lock Assembly (item 16) are

interchangeable, allowing attachment of Side Handle (item 15) on either side

of Angle Head (item 17), for right or left hand operation.

8. Exhaust Cover (item 45) is reversible, for right or left hand operation.

PARTS LIST FOR PN 28824 12,000 RPM