3M FDTC 08S User manual

June 2012

78-8135-6188-9-D 3

3M™Fiber Dome Terminal Closure

FDTC 08S Direct Splice

3M™Fiber Dome Closure FDC 08S-A

Instructions

1.0 Introduction

The 3M™Fiber Dome Terminal Closure FDTC 08S

(Direct Splice) or 3M™Fiber Dome Closure FDC 08S-A

can accommodate up to eight 0.47" (12 mm) cables when

using the 3 mm external cable assembly module (ECAM)

and two 0.79" (20 mm) main cables. The 3M™External

Cable Assembly Module (ECAM) Cable Entry Port Kit is

designed to accept fiber optic loose tube and central tube

cables with external diameters from 0.16" to 0.47" (4–12

mm) and flat drop 0.18" x 0.32". It will accommodate

cables with single or dual cable strength members. The

FDTC 08S direct splice can accommodate both dielectric

and armored drops and cables. For armored cables, the

grounding kit must be purchased separately.

Specifications

Item Qty. Description

Tray Capacity 43M™Fiber Optic Splice Trays

2538

Splice Tray Capacity 24

72

12

Single Fusion (Double Stacked)

Mass Fusion

3M™Fibrlok™ Splices

Max Drops/Branch Cables 80.16" (4 mm) min to 0.47"

(12 mm) max diameter

Main Cables 20.39" (10 mm) min to 0.79"

(20 mm) max diameter

Ground Lugs 0 or 1

Air Valve 5.8 PSI (40 kPa) max flash

Express Storage 72" (1.8 m) max of LBT 72F

(12 fibers/buffer)/RF 144F

2.0 Kit Contents

A. Dome

B. Band

C. Storage tray

D. Base assembly

E. 3M™Double Cable Entry Port External Cable

Assembly Module ECAM-20MM-D

F. Double Cable Entry Port ECAM-20MM-D loose

parts

G. (1) 3M™Fiber Optic Splice Tray

2538-24-DF/72-MF

H. Double Cable Entry Port ECAM-20MM-D

Instructions

I. Fiber Dome Terminal Closure FDTC 08S and

Fiber Dome Closure FDC 08S-A Instructions

A

B

D

E

F

C

G

2 78-8135-6188-9-D

3M™Fiber Optic Splice Tray 2538

A. Splice tray

B. Tray cover

C. (2) 3M™Single Fusion Spice Holder 2521-F

D. (1) 3M™Ribbon Spice Holder 2521-FL

E. Label

F. Cable ties

G. Rubber gripper

A

B

G

D

E

F

C

Visually inspect all components. If any component is

missing or appears damaged, do not install. Call customer

service at 1-800-426-8688 for a replacement product.

3.0 3M™Fiber Dome Terminal Closure

FDTC 08S (Direct Splice) and

3M™Fiber Dome Closure FDC

08S-A Base Configuration

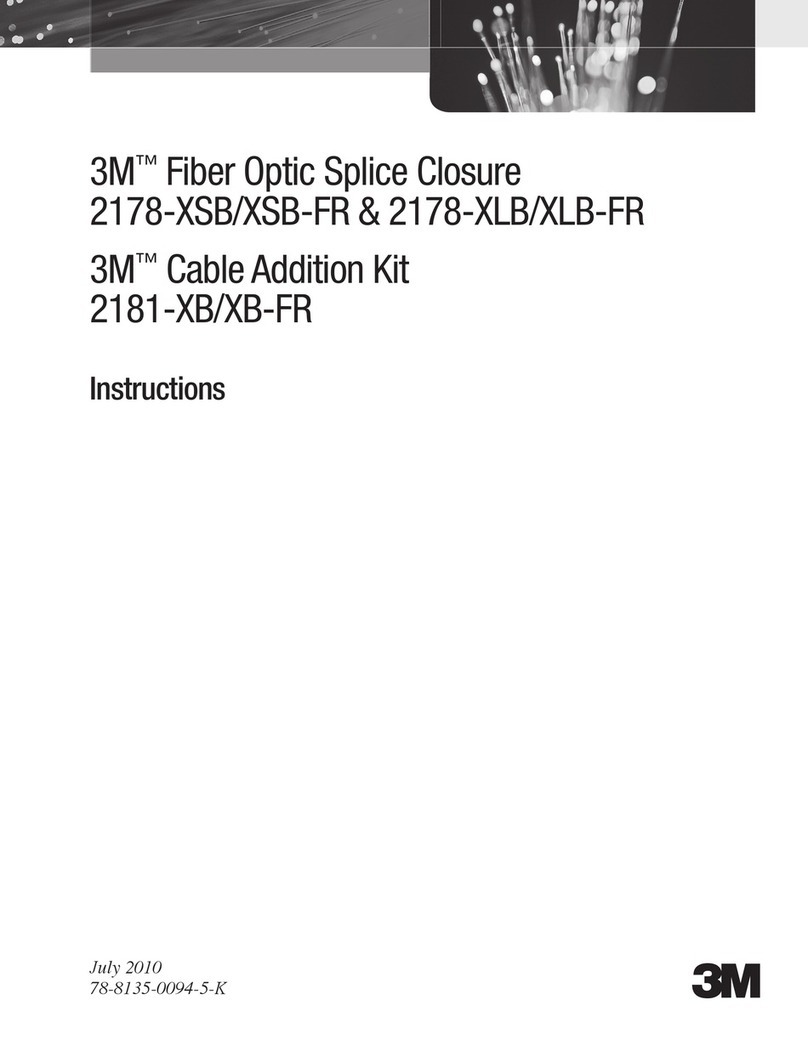

1

234

5

67

8

Ground Stud

1/4-20 Thread

Air Valve

3M™Double Cable Entry Port

ECAM-20mm-D

4.0 3M™Double Cable Entry Port

External Cable Assembly Module

ECAM-20 mm-D Preparation

4.1 Refer to instruction manual 78-8140-3820-3,

3M™Double Cable Entry Port ECAM-20mm-D

for cable seal preparation included in kit.

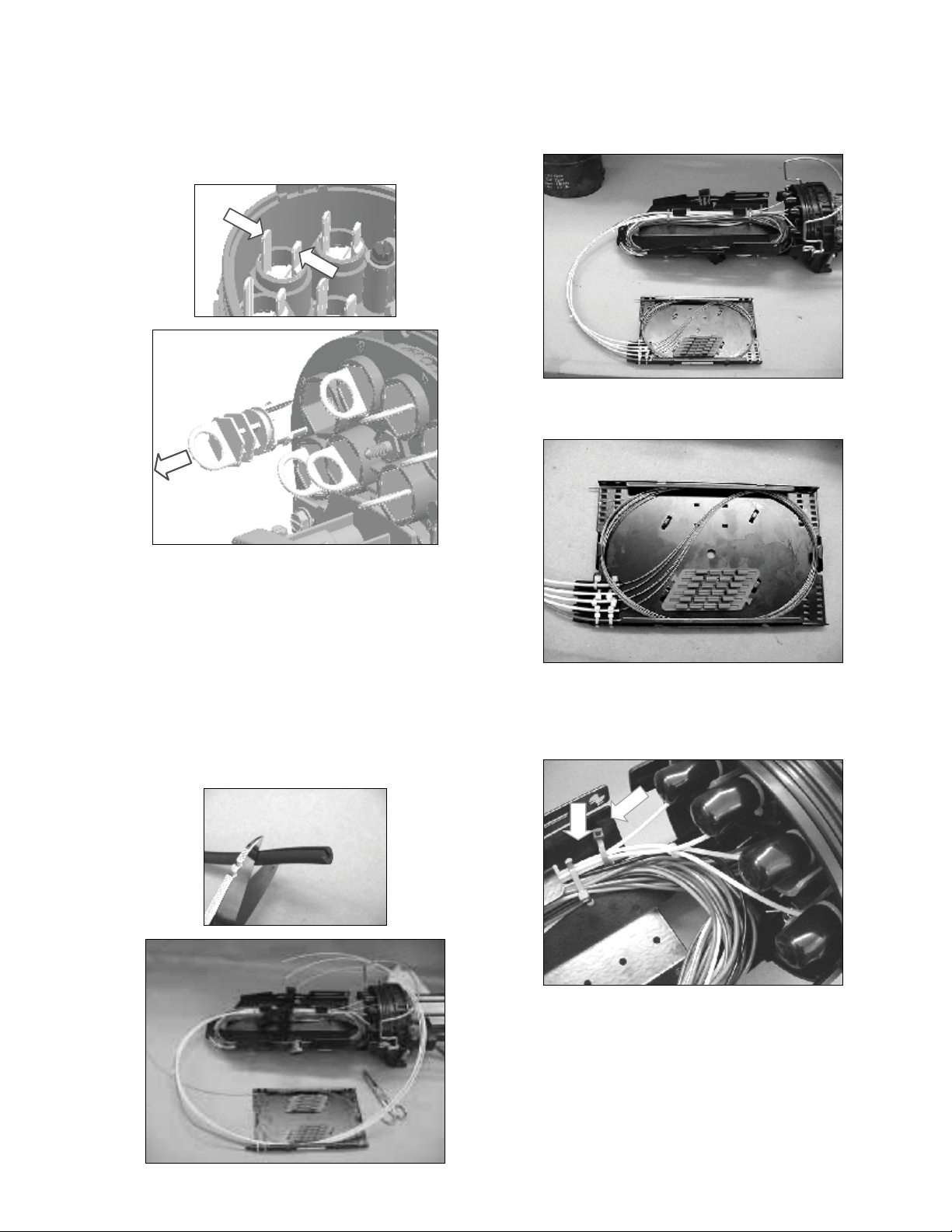

5.0 Fiber Slack Storage

5.1 Determine buffer tube or ribbon to be cut and

cut at appropriate end for splicing.

5.2 Store remaining express fiber slack as shown.

Do not exceed minimum bend radius.

Loose Buffer Tube

Step 1 Step 2 Step 3

Ribbon

5.3 Using cable ties, secure the central tube in the

storage tray as shown.

378-8135-6188-9-D

6.0 Cable Splicing

6.1 Determine type of splice insert needed. 3 mm

diameter fusion sleeves (3M™Fusion Sleeves

2170) are recommended. Smaller diameter

sleeve may require the use of RTV to aid in

retention.

3M™Discrete Fusion 2521-F

3M™2521-FL Mass Fusion and 3M™Fibrlok™ Splices

6.2 Install splice insert into splice tray by slipping

tabs under metal retainers as shown.

6.3 Attach splice log decal to cover.

Note: Bottom portion of decal can be cut off and used

to identify individual trays.

6.4 Place splice tray in storage tray. Tabs on tray

nest between tabs in storage tray.

6.5 If needed, tray can be held in storage tray by

using a cable tie as shown.

6.6 Loosen Buffer Tube

6.6.1 Fiber slack can be store in tray as shown.

4 78-8135-6188-9-D

6.6.2 Route fiber into splice tray to determine

amount of buffer tube to remove. Remove

buffer tube and clean fiber as required.

6.6.3 Cut a one-inch (25 mm) long section of

the rubber gripper supplied with the splice

tray kit and use to secure buffer tubes or

ribbon fiber (up to six ribbons) to tray.

6.6.4 Buffer tube splicing can be done with the

splice tray removed from the storage tray.

6.6.5 Up to four 3M™Fiber Optic Splice Trays

2538 can be stacked in closure.

6.7 Ribbon

6.7.1 Recommend ribbon splicing be done

with the splice tray mounted inside the

storage tray.

6.7.2 Secure tray(s) by attaching retaining strap.

578-8135-6188-9-D

7.0 Drop Port Installation

7.1 Clean any dirt from port in base.

7.2 Determine drop entry port and remove plug by

squeezing tabs together inside base. At the same

time pull ring outward.

7.3 Lightly lube both the O-ring seal area base

port and the 3M™External Cable Assembly

Module (ECAM) Port O-ring using the supplied

lubricant.

Note: Follow health, safety and environmental

information. Refer to product label or Material Safety

Data Sheet for silicone lubricant.

7.4 Cut a one-inch (25 mm) long section of the

rubber gripper supplied with the splice tray kit

and use to secure buffer tubes or ribbon fiber to

tray.

7.5 Splicing can be done with the splice tray

mounted inside the storage tray (recommended

for ribbon splicing) or can be removed as

shown. Route drops into tray to determine

amount of buffer tube to be removed.

7.6 Drops number one to four can be routed as

shown.

7.7 Route drops as shown. Cable tying groups of

buffer tubes together reduces the chance of

kinking the buffer tubes. Secure stored fiber as

needed using cable ties.

6 78-8135-6188-9-D

7.8 To add drop number five through eight

temporarily place the splice tray into the storage

tray and route remaining drop(s) as shown.

Mark tray entry point on buffer tubes.

7.9 Splicing of remaining four drops can be done

outside if desired.

7.10 Example of routing of drops.

7.11 Secure tray(s) by re-attaching retaining strap.

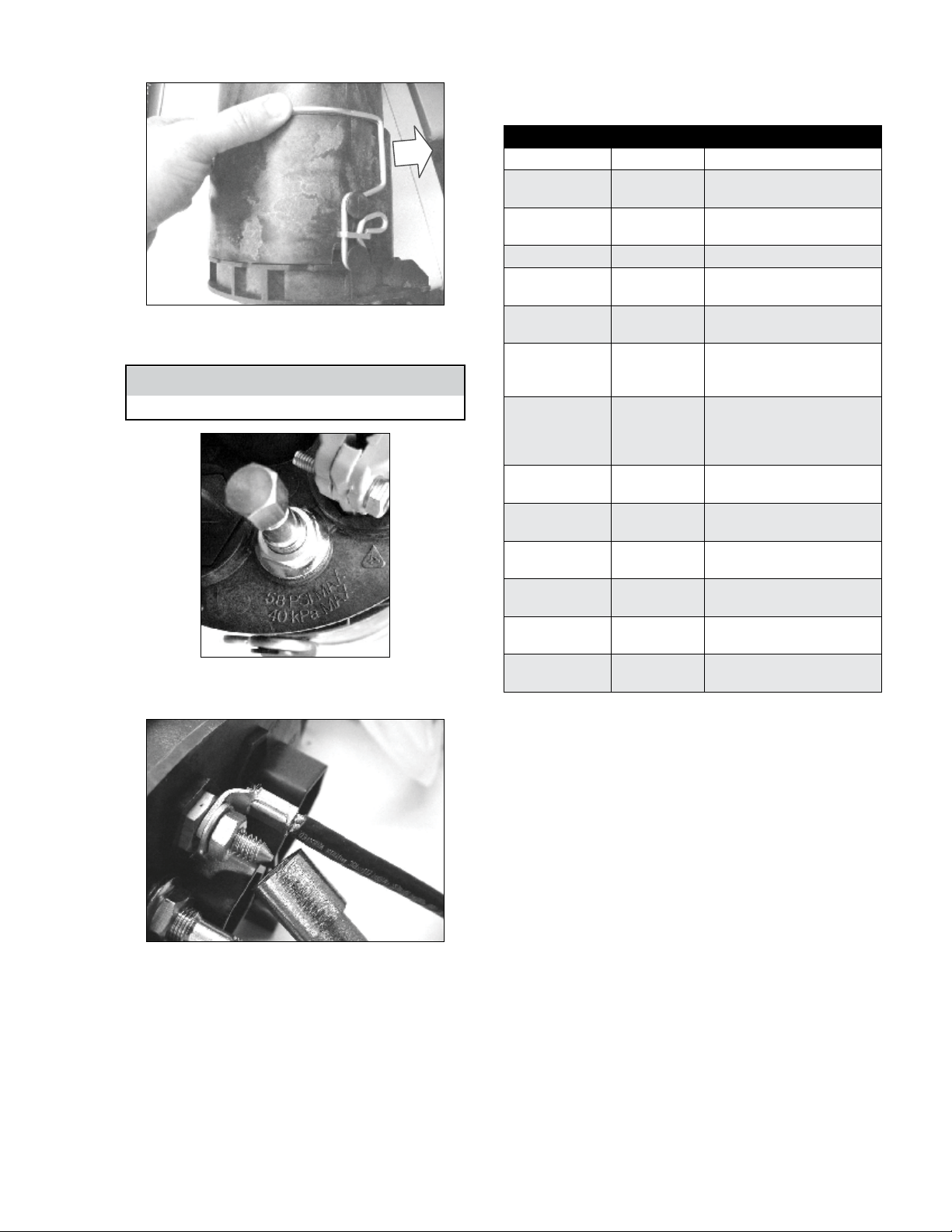

8.0 Closure Sealing

8.1 Ensure both the dome seal area and base O-ring

is free of dirt or any damage. If needed clean

area and apply a light film of supplied silicone

lubricant. Failure to maintain a clean seal area

may lead to leakage.

Note: Follow health, safety and environmental

information and refer to product label or Material Safety

Data Sheet for silicone lubricant.

8.2 Clean and lubricate cable ties, O-ring.

8.3 Replace the dome and engage latch over dome

ear as shown.

778-8135-6188-9-D

8.4 Fully close latch to seat dome onto the base.

8.5 Assembled unit can be flash tested at 5.8 PSI

max (40 kPa max).

Caution

Vent pressure after flash testing.

8.6 External grounding can be added to ground lug

on base.

9.0 3M™Fiber Dome Terminal FDT08

Accessories

Product Number 3M ID Description

ECAM-12MM 80-6113-1696-1 12MM ECAM CABLE ENTRY PORT

ECAM-20MM-D 80-6113-2951-9 20MM DOUBLE CABLE ENTRY

PORT, US

ECAM-GND-6-AWG 80-6113-1702-7 ECAM (18, 20, 27MM) CABLE GND

(6 AWG)

ECAM-GND-14-AWG 80-6113-1704-3 ECAM CABLE GND (14 AWG)

FD-08-HH-1730 80-6113-1706-8 FD08 HANDHOLE MOUNTING

BRACKET FOR 17 X 30

FD-08-AERIAL-SHB 80-6113-1707-6 FD08 AERIAL STRANDMOUNT

HANGER BRACKET

FDST/FDT-08M-

AERIAL-SHB 80-6113-3206-7

AERIAL STRAND MOUNT HANGAR

BRACKET FOR FDST08 AND

FDT08M

FDST/FDT-08-POLE/

PED-HB 80-6113-3205-9

POLEMOUNT, WALMOUNT, BD4,

BD5, CHNL MAH100 PEDMOUNT

BRKT FOR FDST08, FDT08, FDT08M

AND FDT08S

2538-24-DF/72-MF 80-6113-1714-2 2538 F/O SPLTRAY 24 DISCRETE/72

MASS FUSION

2539-12-DF 80-6113-1715-9 2539 F/O SPLICE TRAY 12

DISCRETE FUSION SPLICES

2540-12-DF/36-MF 80-6113-1716-7 2540 F/O SPL TRAY 12

DISCRETE/72 MASS FUSION

FDT-08-PED-CH 80-6113-1720-9 FD08 PED MOUNTING BRACKET

FOR 10” CHANNEL PED

FDT-08-PED-CI 80-6113-1721-7 FD08 PED MOUNTING BRACKET

FOR 8” CHARLES IND PED

2518 80-6113-2634-1 LBT FIBER 2MM TRANSITION TUBE

KIT

3M and Fibrlok are trademarks of 3M Company.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to be reliable, but the accuracy or

completeness is not guaranteed.Before using this product, you must evaluate it and determine if it is suitable for your intended application.You assume all risks

and liability associated with such use.Any statements related to the product which are not contained in 3M’s current publications, or any contrary statements

contained on your purchase order shall have no force or effect unless expressly agreed upon, in writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture for a period of one (1) year from the time of purchase. 3M MAKES NO OTHER

WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

If this product is defective within the warranty period stated above, your exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product

or refund the purchase price of the 3M product. Except where prohibited by law, 3M will not be liable for any indirect, special, incidental or

consequential loss or damage arising from this 3M product, regardless of the legal theory asserted.

3

Communication Markets Division

6801 River Place Blvd.

Austin, TX 78726-9000

1-800-426-8688

www.3M.com/Telecom

Please Recycle. Printed in USA.

© 3M 2012. All Rights Reserved.

78-8135-6188-9-D

Other manuals for FDTC 08S

1

This manual suits for next models

1

Table of contents

Other 3M Network Hardware manuals

Popular Network Hardware manuals by other brands

Matrix Switch Corporation

Matrix Switch Corporation MSC-HD161DEL product manual

B&B Electronics

B&B Electronics ZXT9-IO-222R2 product manual

Yudor

Yudor YDS-16 user manual

D-Link

D-Link ShareCenter DNS-320L datasheet

Samsung

Samsung ES1642dc Hardware user manual

Honeywell Home

Honeywell Home LTEM-PV Installation and setup guide