3T-Components 3T-MOTORS 3T45-10B Manual

3T-MOTORS Shutter / Awning motors

with electronical limit switches

Motor type 3T45-B

(For shafts from 60 mm)

3T45-10B

3T45-20B

3T45-30B

3T45-40B

Motor type 3T35-B

(For shafts from 40 mm)

3T35-10B

3T35-13B

www.3t-components.de |WEEE-Reg.-Nr.: DE 77028333

INTELLIGENT

DRIVES &

CONTROLS

FOR SHUTTERS

AND AWNINGS

INSTALLATION &

OPERATING INSTRUCTIONS

Instructions and notes for installation and operation

Attention:

It is important for the safety of persons

to follow these instructions.

Keep these instructions for future reference.

2

TABLE OF CONTENTS

3T-MOTORS Shutter motors / Awning motors with eletronical limit switches

Guideline / Determine torque Page 3

Safety instructions Page 4

Function overview

Scope of delivery Page 5

Technical data Page 5

Installation notes Page 6

Installation instructions

Installation shutter motor Page 7 – 12

•Installation situation Page 7

•1) Prepare power connection Page 7

•2) Select motor bearing Page 7 – 8

•3) Remove shutter shaft Page 9

•4) Prepare motor for installation Page 9

•5) Mount bearings Page 9

•6) Mount motor with shaft unit Page 9 – 10

•7) Shutter motor wiring Page 10

•8) Setting the end positions Page 11

•Mounting instructions for motor type 3T35-B Page 12

Installation awning motor Page 13 – 15

•1) Preparation Page 13

•2) Prepare motor for installation Page 13

•3) Mounting awning motor Page 13 – 14

•4) Awning motor wiring Page 14

•5) Setting the end positions Page 15

Troubleshooting

What to do when ... Page 16

EU Declaration of Conformity Page 17

Optional accessories tubular motors Page 18 – 19

Hotline

06732 600 0369

CONTACT

3T-Components GmbH & Co. KG

Bahnhofstr. 34

55578 Wallertheim

Email: info@3t-components.de

Tel: +49 (0) 6732-600 03 69

Fax: +49 (0) 6732-600 54 30

Opening hours:

Monday – Friday

8:00 – 17:00

www.3t-components.de

Learn more about us:

3T-MOTORS Tubular motors | Table of contents

© Copyright notice

All contents of these instructions, in particular texts, photographs and graphics,

are protected by copyright. Unless expressly indicated otherwise, the copyright

is held by 3T-Components GmbH & Co. KG. Please ask us if you wish to use

the contents of this document.

3

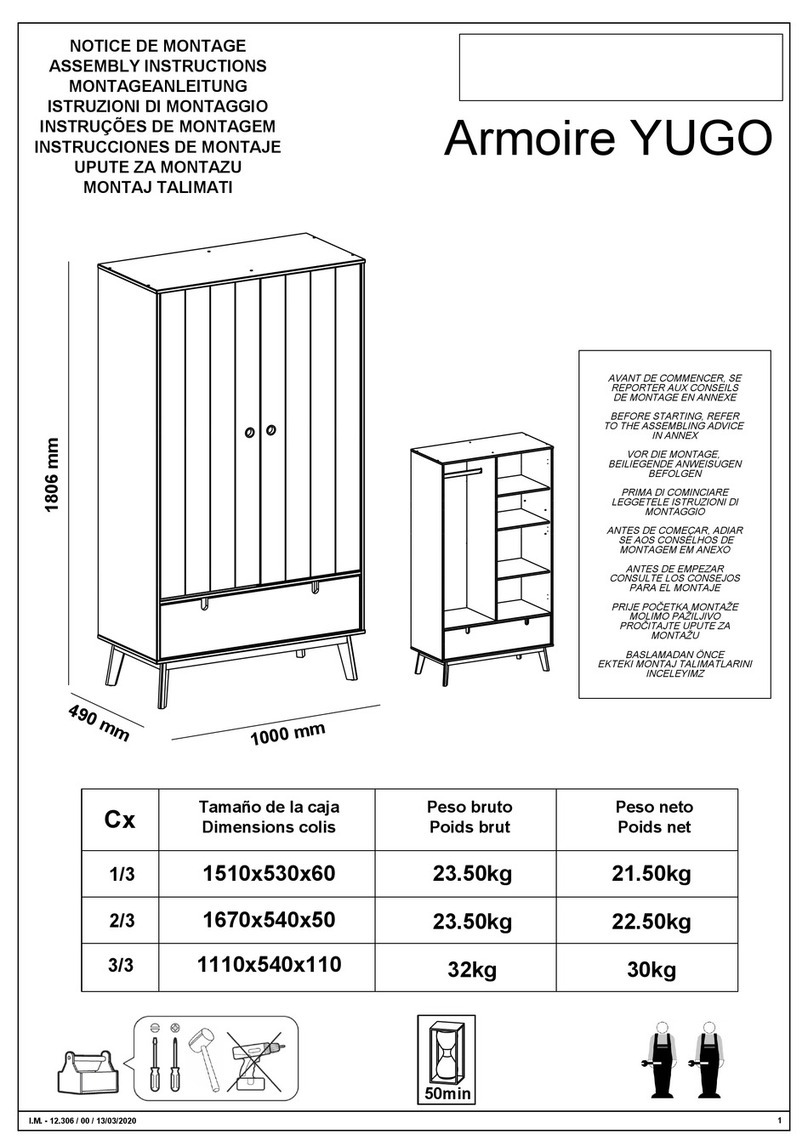

GUIDELINE

With this guide, you can determine the ideal torque in Newton meters (Nm) for the shutter motor.

DETERMINE WEIGHT ROLLER SHUTTER

1.) Determine roller shutter area

(Height + 150 mm) x Width = Roller shutter area (m²)

2.) Determine weight roller shutter material

Take approximate weights per m² of roller shutter area

from the table.

3.) Determine weight roller shutter

Roller shutter area (m²) x weight roller shutter material (m²)

4.) Calculate required traction force

Friction losses must be taken into account

(rail guidance) of approx. 10%!

Roller shutter area (m²) x Weight roller shutter material (m²) = Weight roller shutter (kg) + 10% Friction losses = Required traction force (kg)

Example:

PVC-Roller shutter area 3,00 m² x Weight roller shutter material 5 kg = 15 kg Weight roller shutter + 10% Friction losses = 16,5 kg Required traction force

Material

PVC

Aluminum Light

Aluminum Heavy

Steel

Wood

kg /m²

5

6

9

11

11

DETERMINE SHUTTER MOTOR TORQUE

100

90

80

70

60

50

40

010 20 30 40 50 60 70 80 90 100

515 25 35 45 55 65 75 85 95

10 Nm 13 Nm 30 Nm 40 Nm 50 Nm

Traction force (kg)

ØShaft (mm)

Torque (Nm): 20 Nm

Roller shutter box

Bottom edge

Roller shutter box

Window sill

Height

Width

3T-MOTORS Tubular motors | Guideline

4

GENERAL SAFETY INSTRUCTIONS

IMPROPER USE

PROPER USE

•WARNING: Important safety instructions.

Follow all instructions as incorrect installation may result in serious injury.

•WARNING: The drive must be disconnected from the power source during cleaning, maintenance and replacement of parts.

•Danger to life from electric shock when working on electrical equipment.

• The electrical connection, installation and commissioning of the receiver may only be carried out by qualied personnel.

•Before installing the drive, remove all unnecessary cables and disable all devices,

that are not required for operation with power.

•The relevant regulations and guidelines must be followed without fail, to avoid damage to persons and objects.

•Observe safety instructions according to EN 60 335-2-97: The power supply cable of the drives must be laid internally.

•Installation according to DIN 18073: The roller shutter box cover must be easily accessible and removable.

•Installation according to EN 60335: Only switches / pushbuttons / switching devices with a minimum contact opening

of 3 mm may be used, furthermore the up and down direction must be interlocked against each other.

•When installing in damp rooms, observe regulations (VDE 0100, part 701 and 702).

•These drives can be connected in parallel without an isolating relay or central control.

In this case, the max. output power of the command transmitter (timer or otherwise) must be observed.

•Do not use defective devices: Never use defective equipment.

Periodically inspect the equipment for imbalance and signs of wear or damage to cables and suspension springs.

Do not use equipment if repair or touch-up is necessary.

There is a risk of personal injury and property damage due to electric shock or short circuit.

•Retain the instructions for future reference.

•Use tubular motors only for automating shutters.

•Only use original components and original accessories from the manufacturer.

•The mains connection cable of the drives must be laid internally in the empty conduit up to the junction box.

The local electrical regulations must be observed.

•For the electrical connection of the tubular motors, a 230 V / 50 Hz

power connection with fuse must be available at the installation site.

•Inspect the installation frequently for imbalance and signs of wear or damage to cables and springs.

Do not use if repairs or adjustments are required.

3T-MOTORS Tubular motors | Safety instructions

Please read these important safety instructions before commissioning!

Incorrect installation can cause serious personal injury and damage to property.

The warranty claim expires in case of non-observance of this user information with all contained notes and regulations.

In case of non-observance of these instructions, the manufacturer or supplier shall not be liable for any personal injury or property damage incurred.

SAFETY INSTRUCTIONS

This symbol indicates danger due to electrical energy.

Danger to persons and objects may arise if the

associated information is not observed!

This symbol indicates information about general danger.

Non-observance can mean danger to

persons and objects!

This symbol indicates important information that can

ensure safe and proper use of the device.

•Persons are to be instructed with the correct operation of the tubular motor.

•The roller shutter movement must be monitored in order not to endanger persons.

•Do not allow children to play with motor controls.

•Store the handheld transmitter in such a way that unintentional operation is prevented (e.g. by children playing).

•The device can be used by children aged 8 years and above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge, if they have been given supervision and instruction concerning use

of the appliance in a safe way and are aware of the hazards involved.

•Children are not allowed to play with the equipment.

•If the power supply cord of this device is damaged, it must be replaced by the manufacturer or its customer service

or a similarly qualied person to prevent hazards.

5

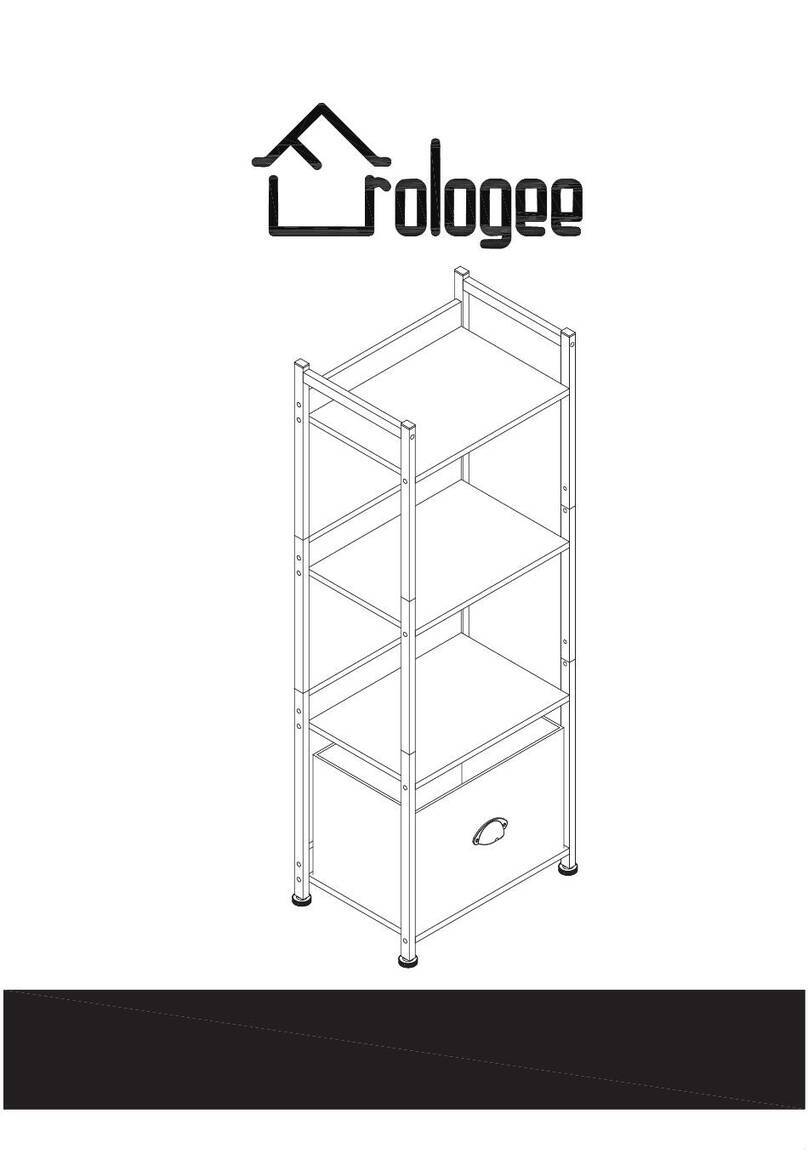

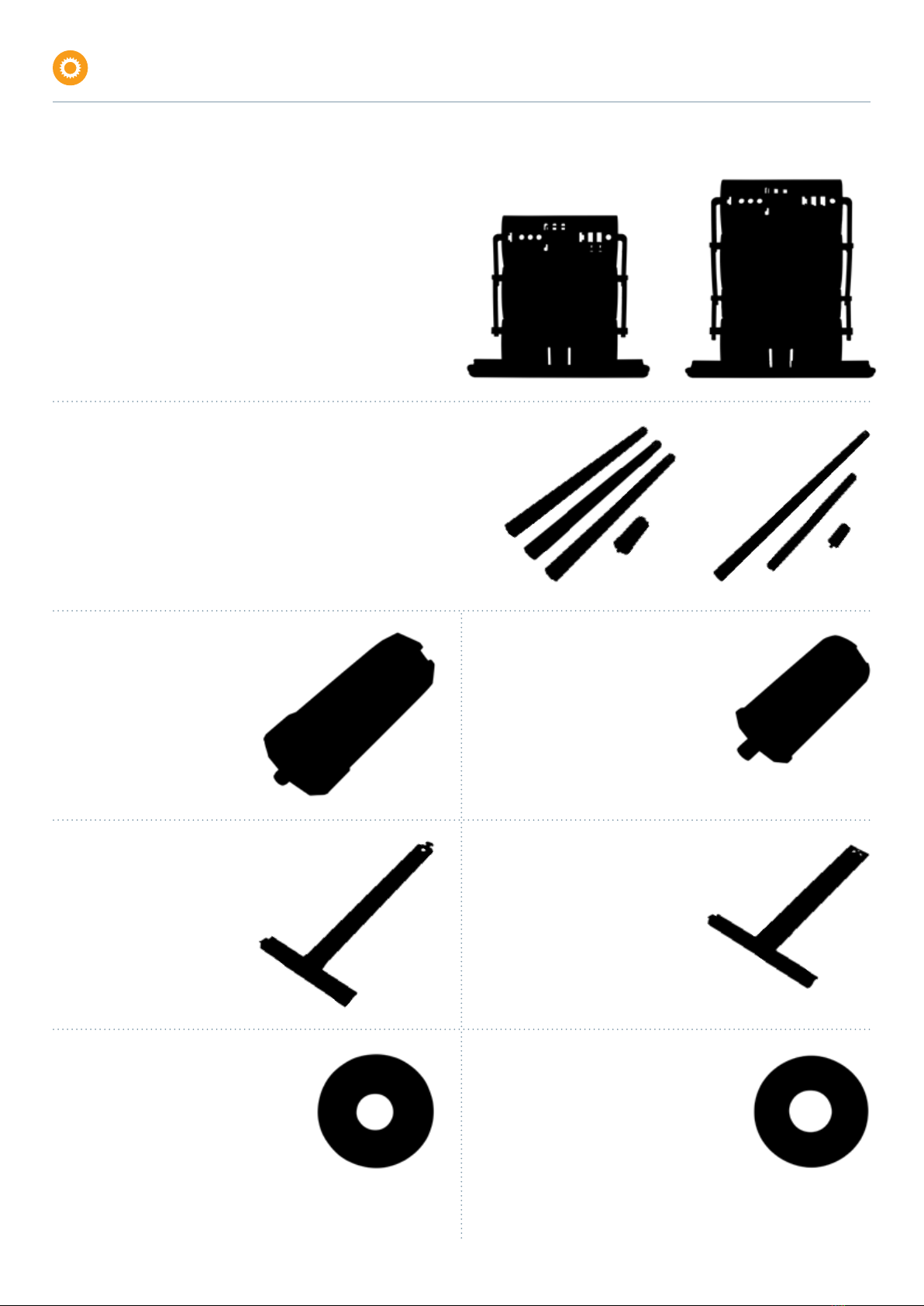

SCOPE OF DELIVERY – MOTOR TYPE 3T45-B

1Motor

2Limit switch adapter

3Shaft adapter

4Connection cable 3 meters

5Universal bearing & cotter pin

6Cover cap bearing (3T45-30B/-40B)

7Clip bearing (3T45-10B/-20B)

8Securing bracket

9 Wire end cap x 2

10 Manual

SCOPE OF DELIVERY – MOTOR TYPE 3T35-B

1Motor

2Limit switch adapter

3Shaft adapter

4Connection cable 3 meters

5Universal bearing & cotter pin

6Clip bearing

7Securing bracket

8Wire end cap x 2

9Manual

Motor type

Torque (Nm)

Traction power (kg)

Max. PVC shutter area (m²)

Max. ALU shutter area (m²)

Power (W)

Turn Speed (U/min)

Limit switch capacity (min)

Operating voltage (V AC)

L1 Total motor length (mm)

L2 Installation length (mm)

Connection line (m)

Max. Runtime (min)

Protection class

EAN

3T45-10B

10 Nm

25 kg

4,5 m²

3 m²

113 W

15 U/min

22 U

230 V

608 mm

587 mm

3 m

4 min

IP44

4260601761380

3T45-20B

20 Nm

40 kg

6 m²

4,7 m²

161 W

15 U/min

22 U

230 V

608 mm

587 mm

3 m

4 min

IP44

4260601761397

3T45-30B

30 Nm

60 kg

9 m²

7 m²

200 W

15 U/min

22 U

230 V

656 mm

635 mm

3 m

4 min

IP44

4260601761403

3T45-40B

40 Nm

80 kg

11 m²

9,5 m²

218 W

12 U/min

22 U

230 V

656 mm

635 mm

3 m

4 min

IP44

4260601761410

3T35-10B

10 Nm

25 kg

5,25 m²

4,2 m²

144 W

17 U/min

30 U

230 V

584 mm

568 mm

3 m

4 min

IP44

4260601761366

3T35-13B

13 Nm

40 kg

7 m²

5,5 m²

144 W

14 U/min

30 U

230 V

584 mm

568 mm

3 m

4 min

IP44

4260601761373

2 31

4

5 6 7 9

APPLICATION

Motorized shutters

SUITABLE FOR

8-sided Shafts from 40 mm

Ø40 mm

Set button Set button

SUITABLE FOR

8-sided Shafts from 60 mm

Ø60 mm

2 31

4

5

6

810

7

Emission sound pressure level LpA ≤70 dB(A)

APPLICATION

Motorized shutters & awnings

Technical data Optional adapter sets + accessories >Optional accessories tubular motors (Page 18 – 19)

9

8

FUNCTION OVERVIEW

3T-MOTORS Tubular motors | Function overview

6

3T-MOTORS Tubular motors | Installation notes

•Do not expose the tubular motor to crushing, impact, falling or contact with any liquids.

Do not punch holes in the entire length of the tube (motor casing) or attach screws to it.

•Please use suitable suspension springs to fasten the roller shutter curtain to the roller shutter shaft.

You will nd suitable suspension springs on page 19 and in our store under mounting accessories.

•Important for motor type 3T35 (SW40):

It is essential to use mini suspension springs for motor operation. These special mini springs protrude only approx.

1 mm into the shaft. This allows the shaft to rotate freely. When using commercially available suspension springs

the motor housing is left with grinding marks because the suspension pin protrudes too far into the roller shutter shaft,

which leads to damage and destruction of the motor.

•For steel shafts with a width across ats of 40 mm (SW40), only use shafts with

an external fold. Steel shafts with an internal fold will damage and destroy the motor.

•Grinding marks of any kind on the motor housing will void the warranty.

•The inspection cover of the roller shutter box must be easily accessible and removable.

•We recommend using a tubular motor with a power 10% higher than the weight of the shutter,

to compensate for the frictional resistance of the rail guide. > See Guideline / Determine torque (page 3)

•The motor is designed for short-time operation (4 min). It has an internal thermal circuit breaker which interrupts

the power supply in the event of overheating, e.g. as a result of continuous operation. The cooling phase is min. 10 min,

the thermal switch resets automatically. Regular operation is only possible after the the motor has cooled down completely.

Mini suspension springs (Page 19)

8-sided shaft SW40

with external fold

Do not use

8-sided shaft SW40

with internal fold!

Before installation, all non-essential electrical wiring must be removed, all mechanisms

that are not necessary for motorized operation must be deactivated.

INSTALLATION NOTES

7

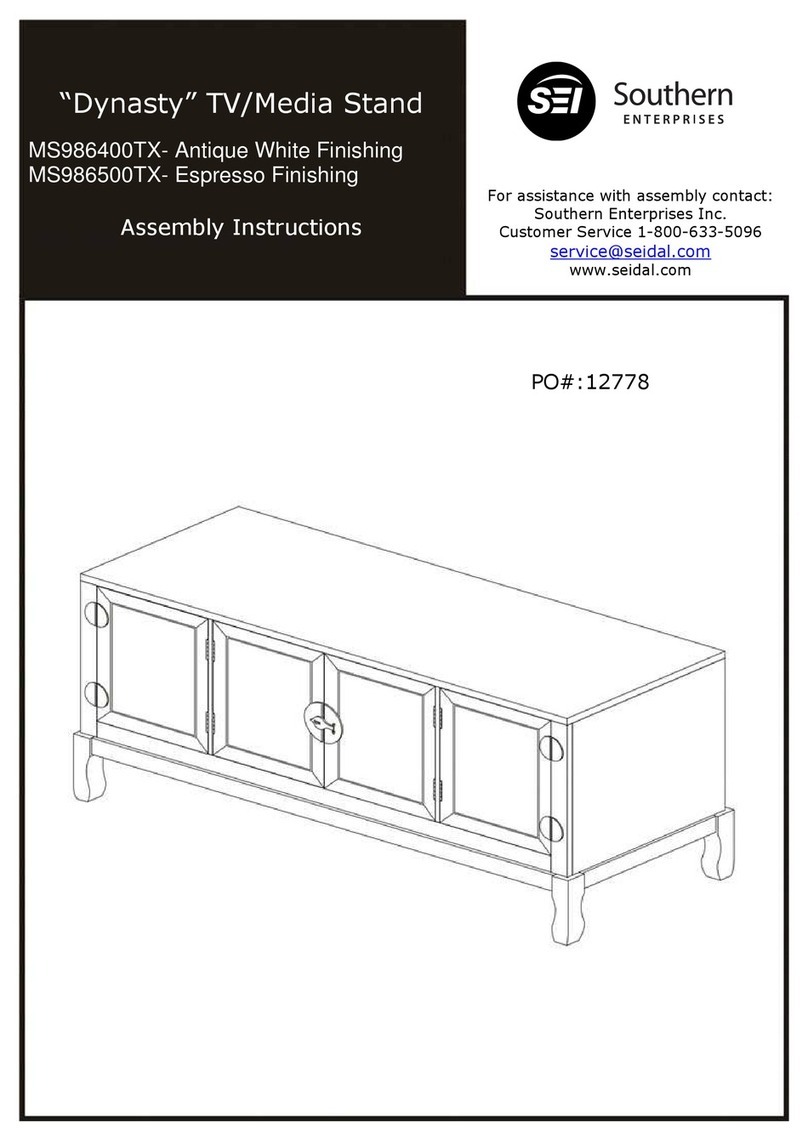

INSTALLATION SHUTTER MOTOR

Installation situation

1Counter bearing*

2Ball bearing*

3Roller capsule*

4Shutter shaft*

5Suspension spring*

6Shaft adapter

7Tubular motor

8Limit switch adapter

10 Limit switches

10 Engine mount

11 Shutter curtain*

* Accessories; not included

1Prepare power connection:

•The mains connection cable of the drive must be laid internally in the empty conduit up to the junction box.

The local electrical regulations must be observed.

2Select motor bearing:

•Two motor bearings are supplied with motor type 3T45-B and 3T35-B: Universal bearing and cover cap bearing (3T45-30B/3T45-40B) / clip bearing.

•Use one of the two motor bearings depending on the installation situation.

1 2 3 4 5 6 7 8 9 10

11

Please note:

•The motor can be installed on the right-hand side as well as on the left-hand side.

If the direction of rotation is reversed, please exchange the wires for the up and down direction.

•The setting of the end positions is only possible in the installed state (motor in shutter shaft).

•Never place screws in the area of the tube motor, as they will damage the motor.

•Engine damage caused by improper use or unprofessional installation,

lead directly to loss of warranty.

INSTALLATION INSTRUCTIONS

3T-MOTORS Tubular motors | Installation instructions

8

Motor type 3T35-B

Installation with universal bearing or clip bearing

Installation with universal bearing:

•Push the motor with the square into the opening of the bearing

and secure with cotter pin.

Installation with clip bearing:

•Remove screws from metal plate on motor head >g. 2.5

•Remove metal plate >g. 2.6

•Remove motor square spigot >g. 2.7

•Reattach metal plate >g. 2.8

•Engage motor type 3T35-B without square spigot in clip bearing.

Motor type 3T45-B

Installation with universal bearing or cover cap bearing / clip bearing

Installation with universal bearing:

•Push the motor with the square into the opening of the bearing

and secure with cotter pin.

Installation with cover cap bearing:

•Remove screws from metal plate on motor head >g. 2.1

•Remove metal plate >g. 2.2

•Remove motor square spigot >g. 2.3

•Reattach metal plate >g. 2.4

•Slide motor type 3T45-B without square spigot into cover cap bearing

and secure with both securing clips / Engage Motor in clip bearing.

2.62.5

2.82.7

Square spigot

Cotter pin

Universal bearing

Cover cap bearing

Cotter pin

Securing clips

Universal bearing Clip bearing

2.1 2.2

2.3 2.4

Square spigot

Clip bearing

3T-MOTORS Tubular motors | Installation instructions

INSTALLATION INSTRUCTIONS

9

3Remove shutter shaft:

•Lower the roller shutter.

•Open the cover of the roller shutter box.

•Release the suspension springs from the roller shutter shaft.

•Lift roller shutter shaft incl. ball bearing out of the holder.

4Prepare motor for installation:

•Push limit switch adapter ush against motor head. >g. 4.1 / 4.2

•Secure the shaft adapter with the supplied securing bracket. >g. 4.3 / 4.4

•Push the motor into the roller shutter shaft without using force (never knock it in). The fold of the shaft must lie over the recess in the shaft adapter. >g. 4.5 / 4.6

•Make sure that the roller shutter shaft is ush with the motor head limit switch adapter. >g. 4.7 / 4.8

5Mount bearings:

•Remove old wall bearing on motor side (left or right installation possible).

•Mount motor bearing at this point (2 mounting options: Universal bearing and cover cap bearing (3T45-30B/-40B) / clip bearing (3T45-10B/-20B and 3T35-B)).

•Please mount the bearings so that the limit switches are freely accessible.

•Make sure that the roller shutter motor with the shaft unit sits horizontally in the roller shutter box.

6Mount motor with shaft unit:

•Insert the motor head (with the entire shaft unit) into the motor bearing and secure it with the supplied cotter pin or securing clips (Cover cap bearing).

4.1 4.2 4.3 4.4

4.5 4.6 4.7 4.8

3T-MOTORS Tubular motors | Installation instructions

INSTALLATION INSTRUCTIONS

Limit switch adapter

Motor head

Securing bracket

Click

Shaft adapter

Roller shutter shaft

Fold

Recess

wrong right

10

Shutter motor

230 V / 50 Hz

Power grid

230 V / 50 Hz

1) white = Programming cable, not assigned

2) black = Departure or ascent

3) brown = Departure or ascent

4) blue = N Neutral conductor

5) green/yellow = PE Protective conductor

1) brown / black = L1 / Phase

2) blue = N Neutral conductor

3) green/yellow = PE Protective conductor

1 (L1)

2 (N)

3 (PE)

2 (Up/Down)

3 (Up/Down)

4 (N)

5 (PE)

1

The connection diagram of time switches differs from this

circuit diagram! Please refer to the corresponding manual

for the connection diagram.

If the end points are set using the ESK setting cable, do not

connect the switch or timer until after the end points have

been set (page 11)!

2 (Up/Down)

3 (Up/Down)

4 (N)

5 (PE)

1

Adjustment cable ESK Shutter motor

230 V / 50 Hz

The white wire is unoccupied and

must be insulated. To do this, push

the enclosed wire end cap onto the

wire end and press it together with

crimping pliers or combination pliers.

Wire end cap

3T-MOTORS Tubular motors | Installation instructions

INSTALLATION INSTRUCTIONS

•On the opposite side of the motor, push the roller capsule out of the roller shutter shaft until it ts into the ball bearing inserted in the wall bearing.

•Fix roller capsule to roller shutter shaft with self-tapping screw. Position the screw at a punched hole. This prevents the screw from slipping.

7Shutter motor wiring:

•Connect the roller shutter motor and switch (or timer) to the mains.

•The electrical connection of the roller shutter motor and control unit may only be carried out by qualied personnel.

•If the drive should run in the opposite direction after installation, the motor’s upstream and downstream leads (brown + black) must be turned.

Roller capsule

Wall bearing +

Ball bearing

11

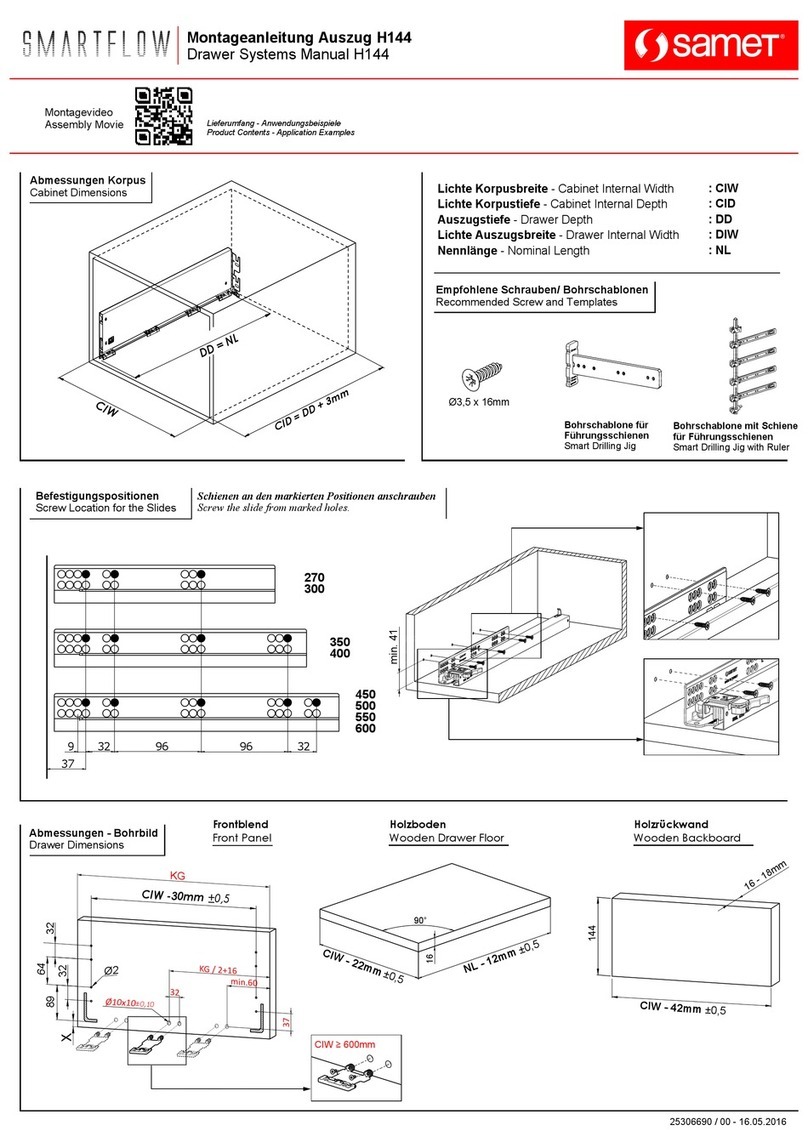

Setting the end points with set button

Connect tubular motor to switch or timer

Test the direction of rotation of the motor and change it if necessary.

•To change the direction of rotation, swap the up and down leads

(brown and black cable) on the switch/timer.

Setting lower end point

•Do not fasten roller shutter armor >g. 8.1

•Set the switch/timer to „DOWN” >g. 8.2

•Run tubular motor in downward direction and dene end point by pressing

set the set button (motor stops) >g. 8.3

•If the shaft has to be turned a little to hook in the suspension springs,

press the set button. This causes the motor to turn the shaft step by step.

Setting upper end point

•Hang the roller shutter curtain with suspension springs on the roller

shutter shaft >Abb. 8.4

•Set the switch/timer to „UP” >Abb. 8.5

•Run the motor with the roller shutter in the upward direction. When the

end point is reached, stop the motor by pressing the set button. >Abb. 8.6

•If the motor stops before the upper end point, a readjustment is possible

by pressing the set button (switch/timer must be set to „UP”).

Continuous pressing = motor continues to move upwards.

Pressing once = motor continues to move upwards step by step.

Setting the end points with adjustment cable ESK

Connect tubular motor to ESK

Test the direction of rotation of the motor and change it if necessary.

•To change the direction of rotation, swap the up and down leads (brown and

black cable) on the adjustment cable

Setting lower end point

•Do not fasten roller shutter armor >g. 8.7

•Set the switch of the adjustment cable to „DOWN” >g. 8.8

•Run tubular motor in downward direction and dene end point by pressing

the green set button (motor stops) >g. 8.9

•If the shaft has to be turned a little to hook in the suspension springs,

press the set button. This causes the motor to turn the shaft step by step.

Setting upper end point

•Hang the roller shutter curtain with suspension springs on the roller

shutter shaft >Abb. 8.10

•Set the adjustment cable to „UP” >Abb. 8.11

•Run the motor with the roller shutter in the upward direction. When the

end point is reached, stop the motor by pressing the green set button. >Abb. 8.12

•If the motor stops before the upper end point, a readjustment is possible

by pressing the set button (ESK must be set to „UP”).

Continuous pressing = motor continues to move upwards.

Pressing once = motor continues to move upwards step by step.

8Setting the end positions:

8.1 8.2 8.3

8.68.4 8.5

8.7 8.8 8.9

8.10 8.11 8.12

Set button

Up button

Down button

INSTALLATION INSTRUCTIONS

3T-MOTORS Tubular motors | Installation instructions

12

MOUNTING INSTRUCTIONS FOR 3T-MOTORS MINI-TUBE MOTORS MOTOR TYPE 3T35-B

Use proper suspension springs:

•To fasten the roller shutter curtain to the roller shutter shaft, please be sure to use

suitable suspension springs for motor operation. These special mini suspension springs only protrude

approx. 1 mm into the shaft. This allows the shaft to rotate freely. When commercially

springs are used, there will be grinding marks on the motor housing because the suspension pin

protudes too far into the roller shutter shaft, which leads to damage and destruction of the motor.

In case of any kind of grinding marks on the motor housing, the warranty claim is void.

•Mini suspension springs > Optional tubular motor accessories (page 18 – 19)

Use correct roller shutter shaft with external fold:

•For steel shafts with a width across ats of 40 mm (SW40), only use shafts with

an external fold. Steel shafts with an internal fold will damage and destroy the motor.

Explanation:

•Avoid overstressing and resulting premature aging of the motor by using the correct suspension

springs and the correct roller shutter shaft with external fold!

•Keep in mind that the motor housing has a diameter of 35 mm and the roller shutter shaft SW40

has an outer diameter of 40 mm. When using commercially available springs or roller shutter shafts

with internal fold, the motor housing will be left with grinding marks, since the suspension pin or the

fold protrude too far into the roller shutter shaft. Contrary to its intended use, the motor runs

permanently against an overload and outside its characteristic data.

•Matching roller shutter shafts SW40 > Optional tubular motor accessories (page 18 – 19)

Mini Suspension spring

8-sided shaft SW40

with external fold

Do not use

8-sided shaft SW40

with internal fold!

Suspension spring

INSTALLATION INSTRUCTIONS

3T-MOTORS Tubular motors | Installation instructions

13

INSTALLATION AWNING MOTOR

1Preparation:

•Screw in awning & secure with straps or ropes.

•Remove awning from wall bracket & place on safe surface.

2Prepare motor for installation:

•Slide limit switch adapter ush against motor head. >g. 2.1 / 2.2

•Secure the shaft adapter with the supplied securing bracket. >g. 2.3 / 2.4

3Installation awning motor:

•Remove the cover to access the side bearing (also awning bracket)

and fastening screws. >g. 3.1

•Loosen the screw that secures the side bearing to the support tube. >g. 3.2

•Remove all screws connecting the side bearing

and the crank mechanism. >g. 3.3

•Remove the side bearing from the support tube. >g. 3.4

•Remove the crank mechanism. >g. 3.5

Attention:

Awning arms are under strong tension!

2.1

Limit switch adapter

Motor head 2.2 2.3

Securing bracket

2.4

Click

Shaft adapter

•Remove the shaft capsule from the shaft. >g. 3.6

If the shaft capsule is tight, use a hammer and screwdriver.

Be careful not to damage the shaft.

•Push the awning motor with shaft adapter rst into the shaft. >g. 3.7

•Make sure motor head & limit switch adapter are ush in shaft.

•Screw the universal bearing onto the side bearing on the side

facing the awning shaft. >g. 3.8

3.7 3.8

Shaft &

wound up

Awning

INSTALLATION INSTRUCTIONS

3T-MOTORS Tubular motors | Installation instructions

Side bearing

Cover

3.1

Support tube

Side bearing

3.2 3.2 3.4

Crank mechanism

3.5 3.6

Support tube

Shaft capsule

Shaft &

wound up

Awning

Universal

bearing

14

•Slide the side bearing with universal bearing onto the support tube & fasten. >g. 3.9

•Ensure that the motor square spigot is properly engaged in the universal bearing. >g. 3.10

•Secure the motor square spigot with the supplied cotter pin. >g. 3.11

•Attach the cover to the side bearing. >g. 3.12

•Install awning & release fuses.

4Awning motor wiring:

•Connect the awning motor and switch (or timer) to the mains.

•The electrical connection of the awning motor and control may only be carried out by qualied personnel.

•If the drive should run in the opposite direction after installation, the motor’s upstream and downstream leads (brown + black) must be turned.

3.9 3.10 3 .11 3.12

Adjustment cable ESK

The connection diagram for the ESK can be found on page 10.

The connection diagram of time switches differs from this

circuit diagram! Please refer to the corresponding manual

for the connection diagram.

If the end points are set using the ESK, do not connect the

switch or timer until after the end points have been set

(page 11)!

Awning motor

230 V / 50 Hz

INSTALLATION INSTRUCTIONS

3T-MOTORS Tubular motors | Installation instructions

Side bearing &

Universal bearing

Support tube

Cotter pin Side bearing

Cover

Power grid

230 V / 50 Hz

1) white = Programming cable, not assigned

2) black = Departure or ascent

3) brown = Departure or ascent

4) blue = N Neutral conductor

5) green/yellow = PE Protective conductor

1) brown / black = L1 / Phase

2) blue = N Neutral conductor

3) green/yellow = PE Protective conductor

1 (L1)

2 (N)

3 (PE)

2 (Up/Down)

3 (Up/Down)

4 (N)

5 (PE)

1

The white wire is unoccupied and

must be insulated. To do this, push

the enclosed wire end cap onto the

wire end and press it together with

crimping pliers or combination pliers.

Wire end cap

15

5Setting the end positions:

Setting the end points with set button

Connect tubular motor to switch

Test direction of rotation

•Press Up button (Arrow up) = Awning moves IN

•Press Down button (Arrow down) = Awning moves OUT

Change the direction of rotation of the motor if necessary

•To change the direction of rotation, swap the up and down leads

(brown and black cable) at the switch

Setting the position „EXTEND”

•Set the switch to „DOWN” >g. 8.1

•Awning moves OUT >g. 8.2

•Run the tubular motor in the „EXTEND” direction and set the end point by

pressing the set button (motor stops). >g. 8.3

•If the motor stops before the „EXTEND” end point, a readjustment is

possible by pressing the set button (switch must be set to „DOWN”).

Continuous pressing = motor continues to extend continuously.

Pressing once = motor continues to extend step by step.

Setting the position „RETURN”

•Set the switch to „UP” >g. 8.4

•Awning moves IN >g. 8.5

•Run the tubular motor in the „RETURN” direction and set the end point

by pressing the set button (motor stops). >g. 8.6

•If the motor stops before the „RETURN” end point, a readjustment is

possible by pressing the set button (switch must be set to „UP”).

Continuous pressing = motor continues to return continuously.

Pressing once = motor continues to return step by step.

Setting the end points with adjustment cable ESK

Connect tubular motor to ESK

Test direction of rotation

•Press Up button = Awning moves IN

•Press Down button = Awning moves OUT

Change the direction of rotation of the motor if necessary

•To change the direction of rotation, swap the up and down leads

(brown and black cable) at the setting cable

Setting the position „EXTEND”

•Set the adjustment cable to „DOWN” >g. 8.7

•Awning moves OUT >g. 8.8

•Run the tubular motor in the „EXTEND” direction and set the end point by

pressing the green set button (motor stops). >g. 8.9

•If the motor stops before the „EXTEND” end point, a readjustment is

possible by pressing the green set button (ESK must be set to „DOWN”).

Continuous pressing = motor continues to extend continuously.

Pressing once = motor continues to extend step by step.

Setting the position „RETURN”

•Set the setting cable to „UP” >g. 8.10

•Awning moves IN >g. 8.11

•Run the tubular motor in the „RETURN” direction and set the end point

by pressing the green set button (motor stops). >g. 8.12

•If the motor stops before the „RETURN” end point, a readjustment is

possible by pressing the green set button (ESK must be set to „UP”).

Continuous pressing = motor continues to return continuously.

Pressing once = motor continues to return step by step.

8.38.1 8.2

8.68.4 8.5

8.98.7 8.8

8.128.10 8.11

INSTALLATION INSTRUCTIONS

3T-MOTORS Tubular motors | Installation instructions

Set button

Up button

Down button

16

... the motor does not run?

•Mains voltage is missing.

•Check correct connection of the control (switch or timer).

... the motor is running in the wrong direction?

•Swap the two wires for the direction of rotation (brown + black).

... the motor does not switch off at the set point?

•Check t of limit switch adapter (must be ush with motor head and shutter shaft).

•Roller capsule is not xed or roller shutter shaft is too short.

... the motor does not switch off at all?

•Limit switches are too far apart: See setting the end points with set button or ESK setting cable (roller shutter motor: page 11 / awning motor: page 15).

... the motor stops running after continuous operation?

•The thermal protection switch of the motor has tripped. After a cooling phase (min. 10 min.), the motor is ready for operation again.

... the motor turns in only one direction?

•Check correct connection of the control (switch or timer).

•Check limit switch: See setting the end points with set button or ESK setting cable (roller shutter motor: page 11 / awning motor: page 15).

... the motor does not operate at the specied speed?

•Check roller shutter weight; if necessary, correct inclined installation of roller shutter shaft or Eliminate mechanical friction in the roller shutter box or rail guide.

TROUBLESHOOTING

WHAT TO DO WHEN ...

3T-MOTORS Tubular motors | Troubleshooting

17

EU Konformitätserklärung

Wir, die Firma 3T Components GmbH & Co. KG

Bahnhofstr. 34

55578 Wallertheim

Deutschland

erklären in alleiniger Verantwortung, dass das weiter unten genannte Produkt

Geräteart:Rohrmotor mit elektronischen Endschaltern

Modell Artikelnummer

3T35-10B365

3T35-13B366

3T45-10B367

3T45-20B368

3T45-30B369

3T45-40B370

die grundlegenden Anforderungen der aufgeführten EG/EU-Richtlinien erfüllt:

2014/35/EU Niederspannungsrichtlinie

2014/30/EU EMV-Richtlinie

2011/65/EU RoHS-Richtlinie

2012/19/EU WEEE-Richtlinie

angewandte Standards und Verordnungen:

EN 60335-1:2012/A13:2017

EN 60335-2-97:2006/A12:2015

EN 55014-1:2017

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

Bevollmächtigter zur Zusammenstellung der technischen Unterlagen:

Name,Position:Patrick El Hadj-Henni, Geschäftsführer

Wallertheim, 08.10.2019

……………………………. …………………………..

Datum Unterschrift

3T-MOTORS Tubular motors | EU Declaration of Conformity

18

OPTIONAL ACCESSORIES TUBULAR MOTORS

ADAPTER SETS 3T35 | ADAPTER SETS 3T45 | MOTOR BEARINGS

Adapter set 40 mm round

•Adapter set for 40 mm round shaft

•Suitable for motor type 3T35/3T35-R

Adapter set 63 mm round

•Adapter set for 63 mm round shaft

•Suitable for motor type 3T45/3T45-R

Adapter set 70 mm round

•Adapter set for 70 mm round shaft

•Suitable for motor type 3T45/3T45-R

Adapter set 85 mm round

•Adapter set for 85 mm round shaft

•Suitable for motor type 3T45/3T45-R

5,7 mm

Ø 38 mm

Ø40 mm

Limit switch adapter Shaft adapter

Ø60,8 mm

14,4 mm

Ø63 mm

14,4 mm

Ø60,8 mm

Limit switch adapter Shaft adapter

Ø67 mm

14 mm

Ø67 mm

14 mm

Ø70 mm

Limit switch adapter Shaft adapter

Ø75,2 mm

15 mm

12 mm

Adapter set 78 mm round

•Adapter set for 78 mm round shaft

•Suitable for motor type 3T45/3T45-R

15 mm

60°

Ø78 mm

Ø75,2 mm

Limit switch adapter Shaft adapter

13,5 mm

Ø82,4 mm

Ø82,4 mm

Ø85 mm

13,5 mm

Limit switch adapter Shaft adapter

Ø 38 mm

Engine bearing /

Roll-off bearing

•Enables the rolling shutter to unroll in

case of defective motor or power failure

•Motor bearing for tubular motors with

Square spigot 10 x 10 mm

•Suitable for all 3T-MOTORS

Tubular motors

Refurbishment bearing /

Push-on bearing

•Adjustable clamp bearing for mounting

onto existing brackets

•Motor bearing for tubular motors with

Square spigot 10 x 10 mm

•Suitable for all 3T-MOTORS

Tubular motors

123,1 mm

55 mm

37 mm

80 mm

39,5 mm

69 mm

35 mm

Adapter set 50 mm 8-sided

•Adapter set for octagonal shafts SW50

•Suitable for motor type 3T35/3T35-R

Ø48,2 mm

7,6 mm

7,6 mm

Limit switch adapter Shaft adapter

Ø48,2 mm

Adapter set 60 mm 8-sided

•Adapter set for octagonal shafts SW60

•Suitable for motor type 3T45/3T45-R

Ø56,7 mm

10,7 mm

12,2 mm

Limit switch adapter Shaft adapter

Ø56,7 mm

Adapter set 70 mm 8-sided

•Adapter set for octagonal shafts SW70

•Suitable for motor type 3T45/3T45-R

15,5 mm

Ø67,4 mm

15,5 mm

Limit switch adapter Shaft adapter

Ø67,4 mm

3T-MOTORS Tubular motors | Optional accessories tubular motors

19

OPTIONAL ACCESSORIES TUBULAR MOTORS

ANTI-LIFT DEVICE | SHUTTER SHAFTS | ROLLER CAPSULE | SUSPENSION SPRINGS | BALL BEARINGS

OCTOCLICK Anti-lift device 2-link / 2,5-link

•Burglar-resistant

•The pushing up of a closed motorized roller shutter is prevented

•For tubular motors with electronic or mechanical limit switching

•For 50 mm (SW50) and 60 mm (SW60) octagonal shafts

• For roller shutter armor with thickness 8 mm + 14 mm (mounting prole can be rotated)

• Made of glass ber reinforced polyamide

•No tooling required

Shutter shafts SW60 / SW40

8kant steel shafts / shaft sets

•SW60 (diameter: 60 mm) up to roller shutter box width:

110 cm / 150 cm / 190 cm / 270 cm / 310 cm / 350 cm

•SW40 (diameter: 40 mm) up to roller shutter box width:

110 cm / 140 cm / 160 cm

Suspension spring Maxi

Required when using roller shutter motors

• Maxi spring up to 65 mm prole height

•For roller shutter shaft SW60

•Powder coated

•Anti-burglary effect

•Pick up width: 100 mm

•Total length: 215 mm

Suspension spring Mini

Required when using roller shutter motors

•For roller shutter shaft SW40

•Powder coated

•Anti-burglary effect

•Pick up width: 100 mm

•Total length: 140 mm

Ball bearing Maxi

Maxi ball bearing for use in roller shutter bearing

•Outer diameter: 40 mm

•Inner diameter: 12 mm

•Specialized trade quality

Ball bearing Mini

Mini ball bearing for use in roller shutter bearing

•Outer diameter: 28 mm

•Inner diameter: 10 mm

•Specialized trade quality

Roller capsule long SW60

High quality product

•Length: 140 mm

•Length Steel pin: 12 mm

•PVC

Roller capsule long SW40

High quality product

•Length: 80 mm

•Length Steel pin: 9,8 mm

•PVC

3T-MOTORS Tubular motors | Optional accessories tubular motors

bit.ly/youtube-3TComponents

Social Media Links

Info, news and tips on roller shutters, awnings, smart home and more:

www.facebook.com/3TComponents www.instagram.com/3tcomponents twitter.com/3TComponents

INTELLIGENT

DRIVES &

CONTROLS

FOR SHUTTERS

AND AWNINGS

Service and

Quality

make the

difference!

3T-Components GmbH & Co. KG

Bahnhofstr. 34

55578 Wallertheim

Email: info@3t-components.de

Tel: +49 (0) 6732-600 03 69

Fax: +49 (0) 6732-600 54 30

www.3t-components.de

Opening hours:

Monday – Friday / 8:00 –17:00

This manual suits for next models

5

Table of contents

Other 3T-Components Indoor Furnishing manuals