508-834-4223 5DTACTICAL.COM 5

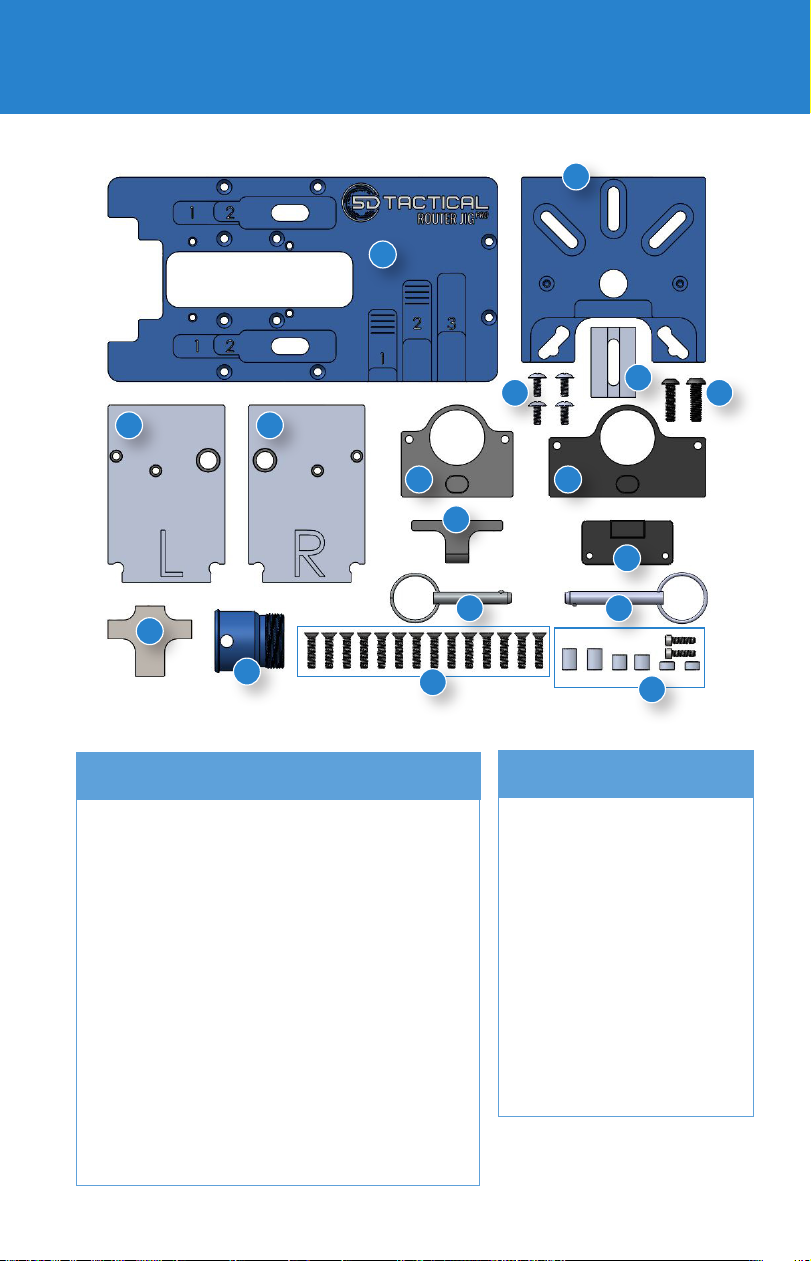

2-2Uninstall the Drill Guide by

removing the (2) Jig Screws.

PART 3: MILLING STEP 1

GO TO APPENDIX A FOR ROUTER ADAPTER

INSTALLATION INSTRUCTIONS

GENERAL NOTES ON MILLING -

READ ENTIRELY:

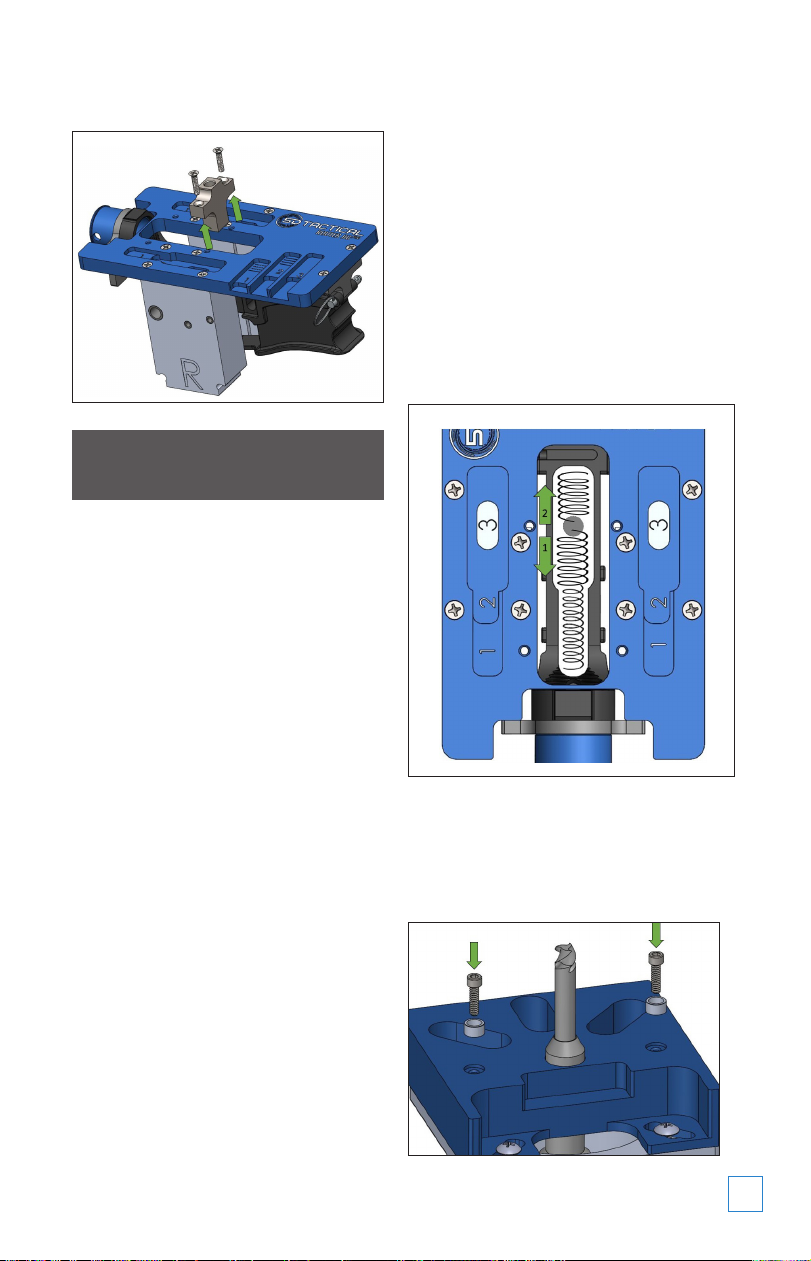

• The provided depth gauge hash marks

denote the maximum depth of cut per

pass. BEGINNERS AND THOSE SEEKING

MAXIMUM FINISH QUALITY SHOULD

MAKE MILLING PASSES AT LESS THAN

A FULL HASH MARK. Attempting to mill

to at depth increments higher than

recommended can cause damage to the

end mill and/or receiver.

• Ensure that your router base lock is

tight and functioning properly. If the

router depth moves while milling,

the end mill and/or receiver can be

damaged.

• If using a variable speed router, set to

the highest speed setting. Do not insert

or remove the end mill while the router is

spinning.

• Prior to turning the router on, ENSURE

THE END MILL IS CENTERED WITHIN THE

MILLING PILOT HOLE AND NOT CONTACTING

ANY PART OF THE RECEIVER.Hold rmly

and apply moderate downward pressure

when starting the router.

• While milling, move the router smoothly

and in a clockwise manner as shown in

the image. Keep the Router Adapter at

against the Guide Plate at all times. Avoid

abruptly pulling the router or exerting

excessive force. Slowly nibble away at

the receiver. If you begin to experience

chattering, slow down and/or take

shallower depths of cut. Apply WD-40 or

cutting uid liberally and remove chips

frequently.

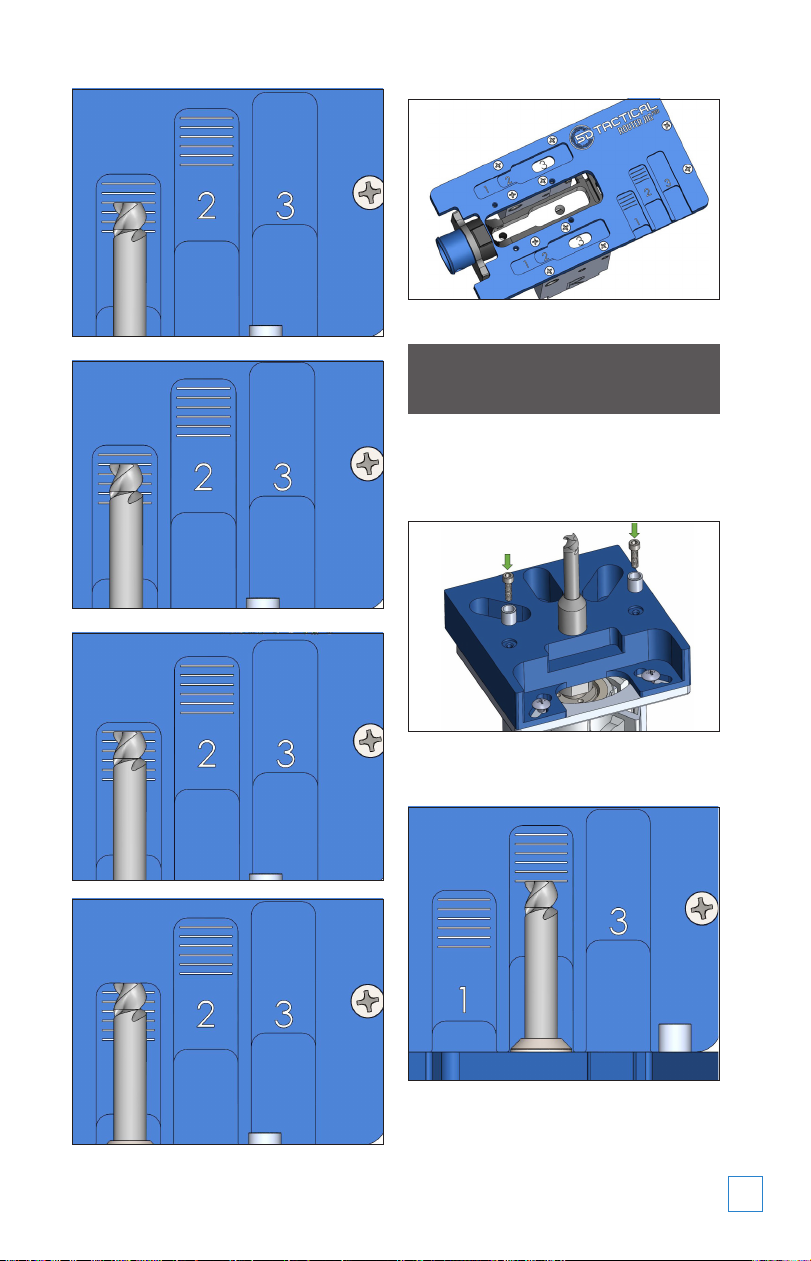

3-1Install #1 (Short) Guide Pins to

Router Adapter using (2) Guide Pin

Screws and 7/64” Allen Wrench. Open end of

pins should be facing up. Do not overtighten.

Make sure pins are fully seated.