Ilsco ND-58 User manual

INSTRUCTION MANUAL

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

ND-58 and ND-60

Mechanical Crimping Tools

999 4935.0 © 2003 Ilsco Corporation 7/03

Ilsco Corporation 24730 Madison Rd. • Cincinnati, OH 45227-1426 • 800/776-9775

ND-58 and ND-60 Mechanical CrimpingTools

All specifications are nominal and may change as design improve-

ments occur. Ilsco shall not be liable for damages resulting from

misapplication or misuse of its products.

KEEPTHIS MANUAL

Description

The ND-58 and ND-60 Mechanical Crimping Tools are

hand-operated tools that use permanent die grooves and/

or insertable W-type dies. They install a full range of

connectors including service entrance, splices, terminals,

stacking lugs, street light, stirrup, and repair sleeves.

The tools have two permanent die grooves, “O” or “BG”

and “D3” for distribution tap connectors. The “D3” groove

also serves as a seat for die inserts to install additional

connectors. The die inserts snap into a permanent “D3”

die holder groove easily with one hand, and are secured

with the spring-loaded, positive lock, die retainer buttons.

The tools incorporate an over center toggle action

mechanism, allowing for easy crimping operations and

field adjustability.

For use on:

• Copper taps from #10 solid to #2/0 stranded

• Aluminum/ACSR taps from #14 solid to #4/0 ACSR

• Stirrups from #6 AWG to #4/0 ACSR

• Copper and aluminum code conductor connectors

from #6 AWG to #4/0 stranded

• Overhead full tension deadend, full and non-tension

splices and terminals from #10 stranded to #4/0 ACSR

• 5/8" and .840" service entrance sleeves

Safety

Safety is essential in the use and maintenance of Ilsco

tools and equipment. This manual and any markings on

the tool provide information for avoiding hazards and

unsafe practices related to the use of this tool. Observe

all of the safety information provided.

Purpose of this Manual

This manual is intended to familiarize all personnel with

the safe operation and maintenance procedures for the

following Ilsco tools:

ND-58 and ND-60 Mechanical Crimping Tools

Keep this manual available to all personnel.

Replacement manuals are available upon request at no

charge.

Warranty and Service

Ilsco warrants this tool to the original purchaser for a

period of one year from the date of purchase, provided the

tool is operated, maintained and used in accordance with

Ilsco’s written instructions. Ordinary wear and tear,

damage from abuse, neglect or alterations are not covered

by this warranty. This warranty is null and void if instruc-

tions and operating procedures are not followed. Contact

Ilsco for all warranty and service issues at 800-776-9775.

Electric shock hazard:

This tool is not insulated. Do not use

on live circuits.

Contact with live circuits can result in

severe injury or death.

An incomplete crimp can cause a fire.

Use proper connector and cable combinations.

Improper combinations can result in an incomplete

crimp.

Failure to observe this warning can result in severe

injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris.

• This tool is intended for two-handed operation.

Maintain a firm grip on both handles when using

this tool.

• Inspect tool before use. If any parts are worn or

damaged, send the tool to an authorized Ilsco

service center.

• Do not perform any service or maintenance other

than as described in this manual.

• Do not exceed the rated capacity of this tool.

Failure to observe these precautions can result in

injury or property damage.

IMPORTANT SAFETY INFORMATION

Ilsco Corporation 34730 Madison Rd. • Cincinnati, OH 45227-1426 • 800/776-9775

ND-58 and ND-60 Mechanical CrimpingTools

Specifications

Crimp Force Developed .......................4091 kg (9000 lb)

Weight (tool only) ..........................................2.7 kg (6 lb)

Operation

Die Selection

• For the ND-60, the upper opening is a “BG” die.

• For the ND-58, the upper opening is an “O” die.

• For both the ND-58 and ND-60 tools, the lower

opening is a “D3” die.

• Interchangeable dies may be used in the lower die

opening. Dies that may be used include:

— Ilsco ND series

— Greenlee KD6 series

— Burndy W and X series

— Huskie HT58 series

— Panduit CD-2001 series

— Other industry W-type dies

Operation Procedure

1. Select the proper dies for the connector to be

crimped.

2. Install dies in jaws making certain that they are

properly secured by the spring-loaded, positive lock,

die buttons.

3. Insert conductor into the connector and align the tool

and die on the connector. Start in the center for

splices and “H” frames, and on the end, nearest the

pad, for terminals.

4. Operate the tool by closing, and allowing, the handle

butt/stop blocks to touch. Normally a “pop” will be

heard as the tool goes over center after the crimp is

made.

5. Continue crimping the connector until the correct

number of crimps have been completed. Work from

the center to the outer edges for splices and “H”

frame connectors, alternating sides if possible, for

the best compression connection.

6. Reposition tool for next crimp, if required. Unless

non-bowing dies are used, it is recommended that

the tool be rotated 90°for each adjacent crimp on

large splice connections.

To help minimize hand and arm fatigue and

perceived handle force during use, hold the

crimping tool with your hands at the end of the

handles.

Inspection and Adjustment

Check tools periodically for correct adjustment. As with

any tool, a slight amount of wear may occur over time.

This wear may be corrected by readjusting the tool as

follows:

1. Remove any die inserts from the tool and make sure

the jaw tips are free of dirt, etc.

2. Open tool and close handles until jaw tips just touch.

DO NOT CLOSE HANDLES COMPLETELY!

3. Check that the index marks (red grooves) on the

toggle link and frame line up.

Adjusting

Set Screw

Locking

Set Screw

4. If the marks line up, the tool is in proper adjustment.

5. If the marks do not line up, loosen the locking set

screw using a 1/4" (6.4 mm) hex key, and then turn

the adjustment screw clockwise or counterclockwise

until the marks line up.

6. Tighten the locking set screw securely; the tool is

now properly adjusted and ready for use.

Correct Adjustment

required

Ilsco Corporation 44730 Madison Rd. • Cincinnati, OH 45227-1426 • 800/776-9775

ND-58 and ND-60 Mechanical CrimpingTools

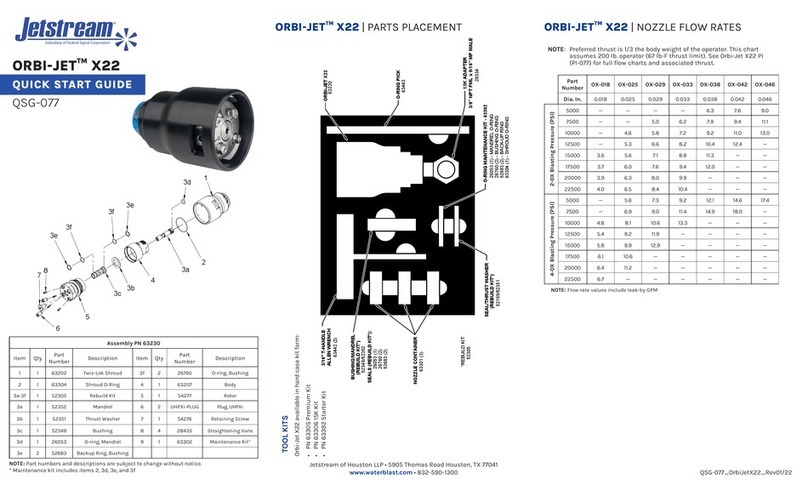

Illustration and Parts List

Key Description Qty

1 Jaw (ND-60)......................................................................... 2

Jaw (ND-58)......................................................................... 2

2 Bushing, oil free ................................................................... 3

3 Spring, ø 6 x L10.8 .............................................................. 2

4 Pin, push .............................................................................. 2

5 Nut ....................................................................................... 2

6 Spindle ................................................................................. 1

7 Link ...................................................................................... 2

8 Bolt, shoulder ....................................................................... 2

9 Nut ....................................................................................... 2

10 Head, handle (A).................................................................. 1

11 Head, handle (B).................................................................. 1

12 Toggle .................................................................................. 1

13 Pin, drive .............................................................................. 1

14 Bolt, shoulder ....................................................................... 3

15 Nut ....................................................................................... 3

16 Screw ................................................................................... 1

17 Screw ................................................................................... 1

18 Tube, shrinkage ................................................................... 2

Repair Kits

500 2793.0 Kit, blade replacement (ND-58);

includes two of items 1–5, 7–9, and one of item 6

500 2794.8 Kit, blade replacement (ND-60);

includes two of items 1–5, 7–9, and one of item 6

500 2137.0 Kit, plate replacement; includes two of items 7–9

500 2148.6 Kit, handle-adjusting replacement;

includes one of items 10, 12–18

500 2149.4

Kit, bolt-handle replacement; includes three of items 2, 14, 15

500 2150.8 Kit, pin-die replacement; includes two of items 3–5

500 2152.4 Kit, handle replacement;

includes one of items 11, 18, and two of items 14, 15

500 2151.6 Kit, screw-set; includes one of items 16, 17

15

15

2

17

16

9

9

714

15

1

3

4

5

8

3

4

8

7

6

5

13

2

12

14

14

1

18

18

10

2

11

Printed in the USA

U.S.TECHNICAL SUPPORT

1-800-776-9775

Ilsco Corporation • 4730 Madison Road, Cincinnati, Ohio 45227-1426

Phone (800) 776-9775, (513) 533-6200 • Fax (513) 871-4084

This manual suits for next models

1

Popular Tools manuals by other brands

Greenlee

Greenlee EK1550FLT Operation manual

TRUPRO

TRUPRO MD-20/25 Operation manual

PICOTE

PICOTE Small Grabber Value Operation & safety manual

Piper

Piper PA-44-180 Seminole 1979 Pilot's operating handbook and faa approved airplane flight manual

Parkside

Parkside PSS 65 A1 Translation of the original instructions

MAGNITUDE LIGHTING

MAGNITUDE LIGHTING CFLEX user manual

JETStream

JETStream ORBI-JET X22 quick start guide

Lincoln

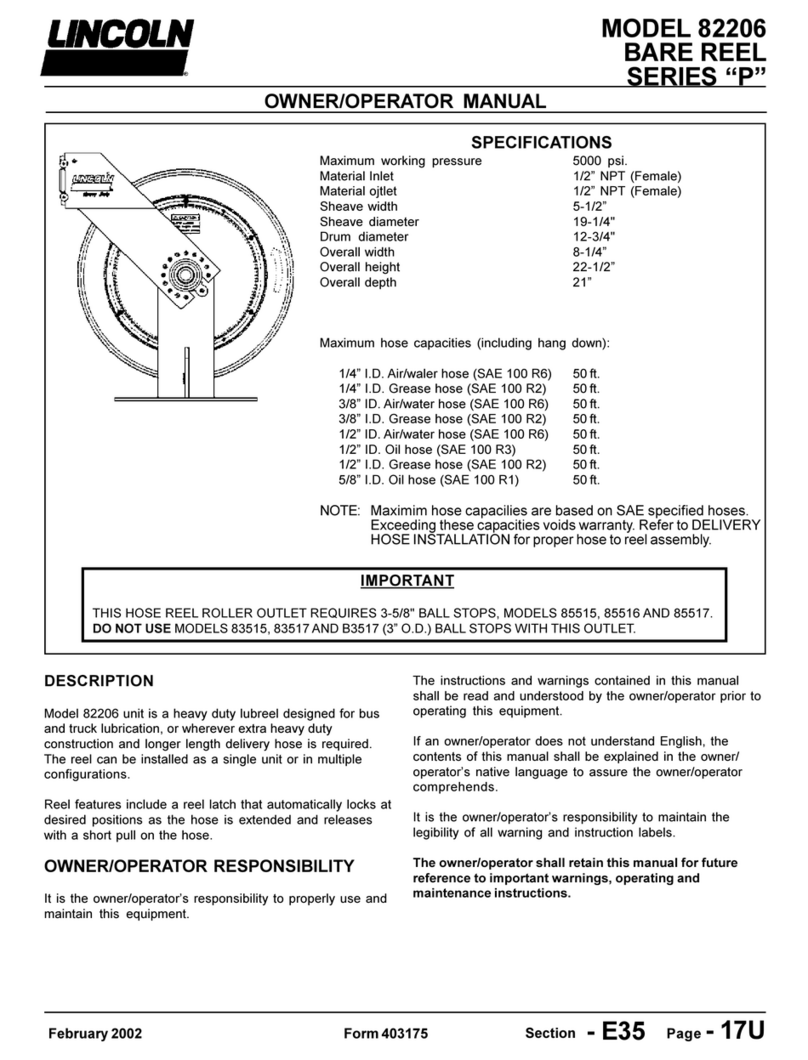

Lincoln 82206 Owner's/operator's manual

Parkside

Parkside 373883 2104 operating instructions

BGS technic

BGS technic 9687 instruction manual

Mitchell Golf

Mitchell Golf Steelclub user manual

Heinrich König

Heinrich König picobello G43860 quick start guide