TECHNICAL MANUAL 620020E05

Due to the continuous products improvement, the indications of the present manual can be modified without previous warning and in any

case are a contract commitment. The present information publishing does not represent resignation of intellectual property or patent.

Copyright 2009-2010 S.A. Sistel -E 08211 BARCELONA Pag. 3

TABLE OF CONTENTS

0. Before you begin ............................................................................................................4

1. Safety...............................................................................................................................4

1.1 Symbols and safety terms .........................................................................................4

1.2 Precautions against damage to people .....................................................................5

1.3 Precautions against damage to the product ..............................................................5

2. Limits of the guarantee..................................................................................................5

3. Description and main features ......................................................................................6

3.1 General features........................................................................................................6

3.2 Typical applications with YAV904X8 .........................................................................6

3.3 Ordering information..................................................................................................7

3.4 Device electrical Characteristics................................................................................7

3.5 Block diagram............................................................................................................8

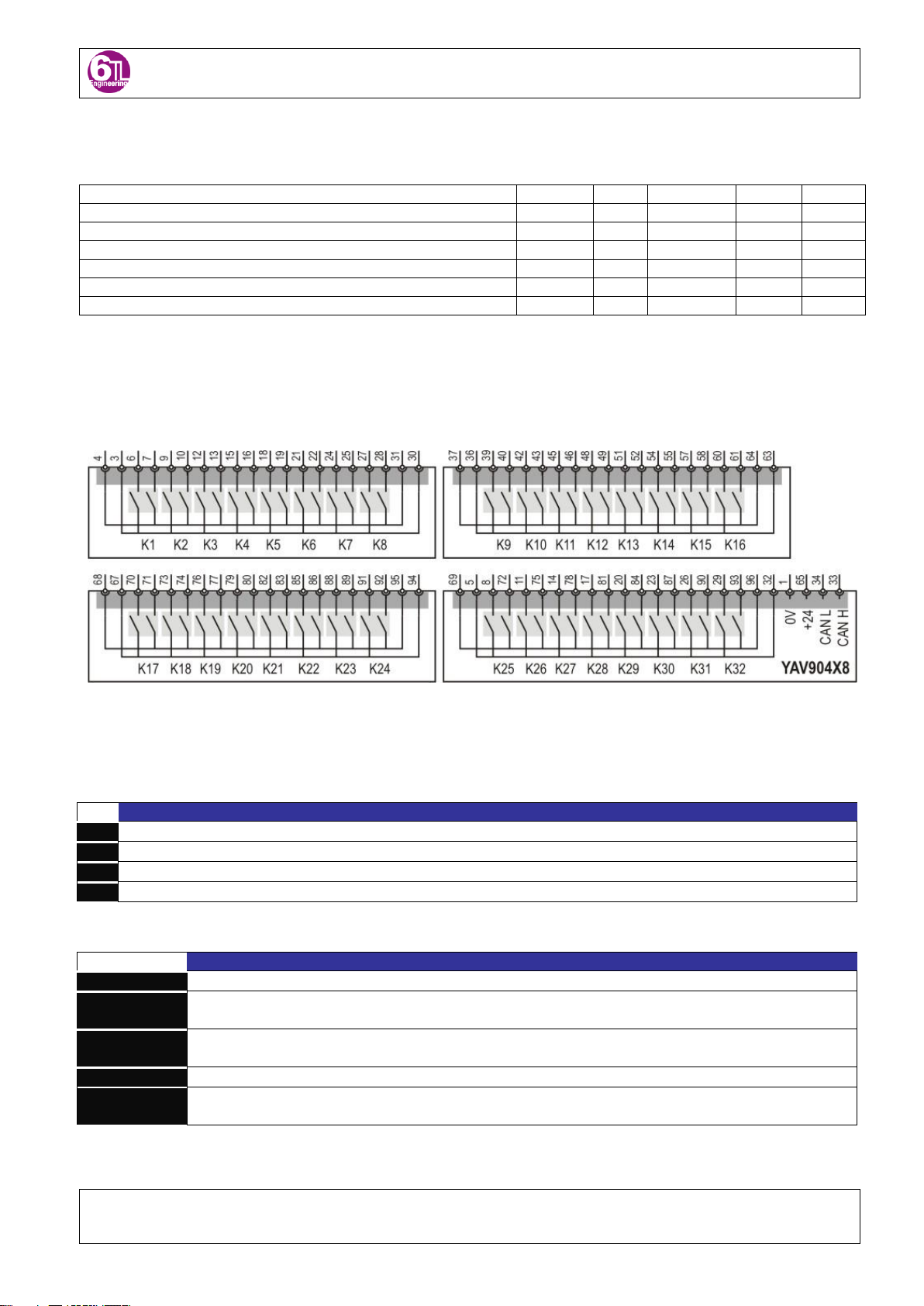

3.6 Connectors & Jumpers..............................................................................................8

3.6.1 X1 Connector (Device Power & CAN)................................................................8

3.6.2 Jumpers..............................................................................................................8

3.6.3 X2 Connector (Relays).......................................................................................9

3.6.4 LEDs ..................................................................................................................9

3.7 YAV904X8 Dimensions...........................................................................................10

4. Low level CAN commands...........................................................................................11

4.1 Example: Managing a YAV board using C language...............................................11

5. PHI6-Explorer panel......................................................................................................14

6. Install/Uninstall YAV modules into/from a VPC Receiver .........................................16

6.1 Receiver connector..................................................................................................16

6.1.1 YAVs with 96 pin connector..............................................................................16

6.2 Connections.............................................................................................................17

6.2.1 Connecting cables into YAV module terminals.................................................17

7. Getting started with your YAV module.......................................................................18

7.1 CAN Interface..........................................................................................................18

7.2 CAN bus wiring........................................................................................................18

7.3 PHI6-EXPLORER....................................................................................................18

8. YAV modules overview ................................................................................................19

8.1 YAV modules common information .........................................................................19

8.1.1 SW1 DIP switch functionality............................................................................19

8.1.2 CAN bus communication speed.......................................................................19

8.1.3 YAV module address........................................................................................20

8.2 YAV modules standard addressing & Virginia Panel Receivers..............................20

9. Certifications.................................................................................................................24

10. Test................................................................................................................................25