A.E.B. AEB214 PLUS User manual

Any information supplied in this manual can be changed at any

moment by A.E.B. in order to update it according to any quality

and informative variation or technological improvement.

This manual is a property of A.E.B. and cannot be reproduced

or copied without its previous consent.

OBD2 Diagnosis Hand-Held Tester

AEB214 PLUS

Cod. 616000191

Instruction manual

616000191_ENG Rev. 111114-0

2 - 12

TABLE OF CONTENTS

1. General Description ..................................................... Pag.3

1.1 Description of the Tester ........................................................... Pag. 3

1.2 Pack contents ............................................................................ Pag. 3

1.3 Switching on the Tester............................................................. Pag. 3

1.4 Connecting to the control unit ................................................... Pag. 4

1.5 Identifying the type of connection and the type of OBD2 μFIX Emulator Pag. 4

2. Menus.......................................................................... Pag.5

2.1 Parameters.............................................................................. Pag. 5

2.2 Trouble codes (DTC) ................................................................ Pag. 5

2.3 Freeze frame ........................................................................... Pag. 6

2.4 Latent Trouble Codes............................................................... Pag. 6

2.5 Clear trouble codes.................................................................. Pag. 7

2.6 Permanent Trouble Codes........................................................ Pag. 7

2.7 Vehicle Data ............................................................................ Pag. 7

2.8 O2 Sensor Monitoring .............................................................. Pag. 8

2.9 Component Monitoring ............................................................ Pag. 8

2.10 Performance Tracking ............................................................. Pag. 8

3. Programming and updating the tester ......................... Pag.9

3.1 Connection for reprogramming/updating ................................. Pag. 9

3.2 Updating/reprogramming procedure........................................ Pag. 9

3.3 Features of the AEB214 PLUS tester ......................................... Pag. 10

4. Certicate of warranty ................................................ Pag.11

616000191_ENG Rev. 111114-0 3 - 12

The AEB214 PLUS Hand-Held Tester can be used with all vehicles that use OBD2 (American standard)

and EOBD (European standard) diagnostic systems.

The following operations can be performed with the AEB214 PLUS Tester:

- display of vehicle operating parameters (engine RPM, engine temperature, etc.);

- readout and zeroing of errors stored by the original injection control unit;

- determination of the type of OBD2 µFIX Emulator required for the vehicle connected to the Tester.

The Tester is equipped with a reprogrammable memory that enables the unit to receive future updates and

partially complies with ISO 15031-4.

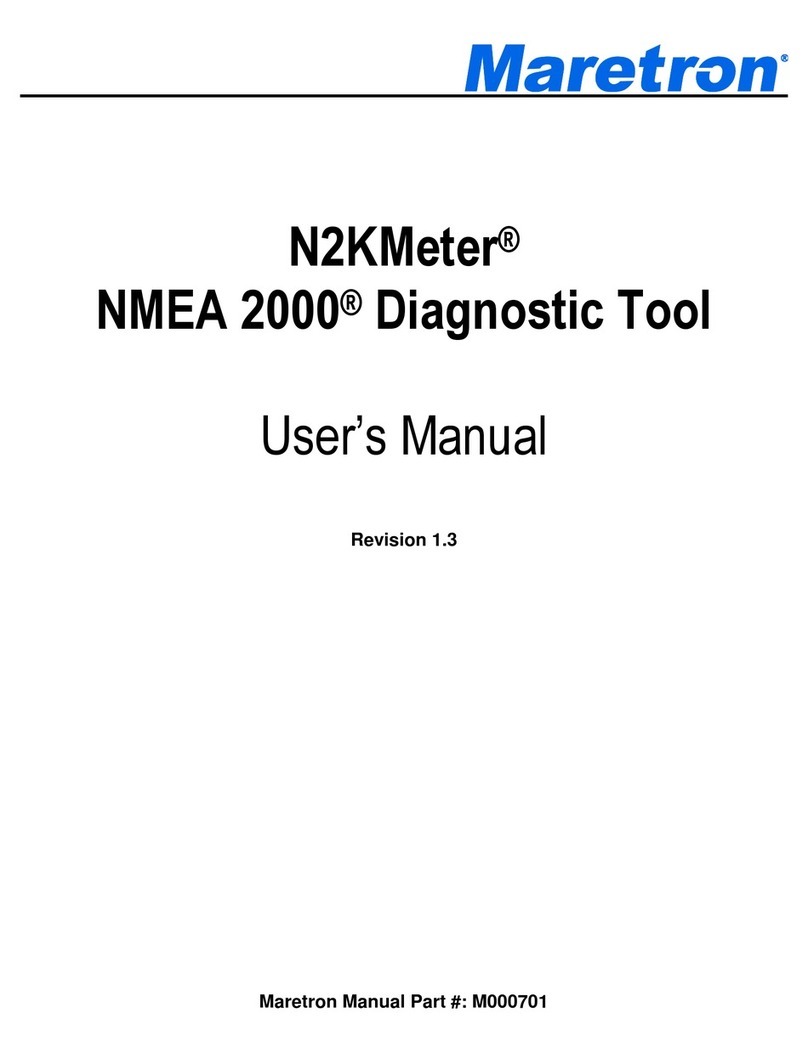

1.1 Description of the Tester

1) Micro USB port for connection to a PC.

2) Connector for connecting to the diagnostic port on the vehicle.

3) Backlit dot-matrix LCD display.

4) [ ESC ] key for exiting the page and returning to the previous menu.

5) [ ] key for moving the cursor or scrolling the page upwards.

6) [ OK ] key for conrming data or entering a page.

7) [ ] key for moving the cursor to the previous page.

8) [ ] key for accessing the help page.

9) [ ] key for moving the cursor to the next page.

10) [ C ] key for deselecting parameters.

11) [ ] key for moving the cursor or scrolling the page downwards.

12) [S ] key for selecting parameters.

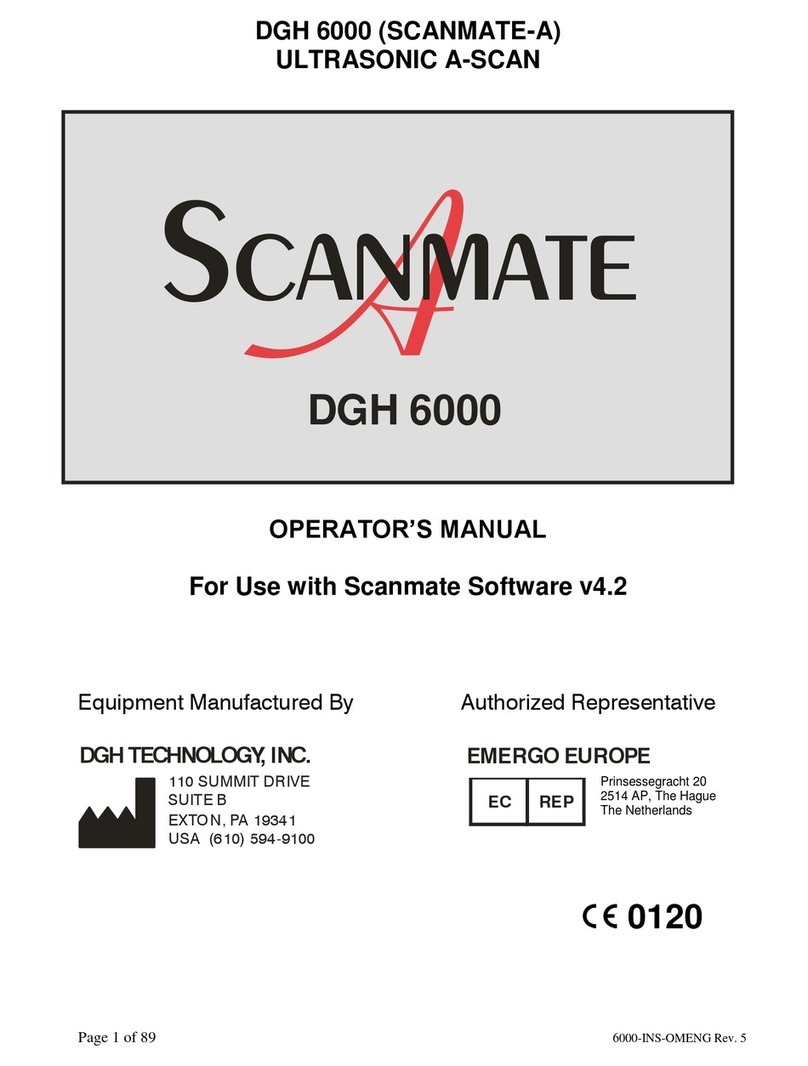

1.2 Pack contents

The Tester is supplied in a carrying case that contains:

1 OBD2 Diagnostic Tester.

1 cable for connecting to an OBD diagnostic port (type SAE J1962 /

ISO15031-3).

1 USB/microUSB cable for connecting the tester to a PC.

1.3 Switching on the Tester

The AEB214 PLUS Tester switches on automatically when it is connected

to the vehicle’s diagnostic port using the cable provided. When it

switches on, the A.E.B. logo and the version of the programme appear

on the display (Fig. 1).

Press the ESC or OK key to access the main page (Fig .2). Press any

other key to select the desired language.

12

3

5

6

4

9

7

12

11

10

8

TESTER-to-OBD CONNECTING

CABLE

VEHICLE OBD

CONNECTOR

OBD TESTER

Code AEB214 PLUS

616000191_ENG Rev. 111114-0

4 - 12

1.4 Connecting to the control unit

Be sure the ignition is on. From the main page on the Tester (Fig. 2),

the following commands can be run:

Press the [ ] key to display a help message.

Press the [S] key to display battery voltage.

Press the [C] key to adjust the brightness and contrast of the display.

Press the [ ] [ ] keys to select the language.

Press the [ ] [ ] keys to select the connection protocol manually.

Press the [ESC] key to return to the main/previous screen.

Press the [ OK ] key to connect to the control unit. The display will

show

, “Finding Connection - Please Wait” for a few seconds.

After communication has been established, “Connection Type” will appear on

the display (Fig.3, see the types of connection in paragraph 1.5).

Press the [ OK ] key to move to the next page (Fig.4), where one of

the following options can be selected:

Parameters, Diagnostic Trouble Codes (DTC), Freeze Frame,

Latent Trouble

Codes, Clear DTCs, Permanent Trouble Codes, Vehicle Data,

Component Monitoring, Performance Tracking, O2 Sensor

Monitoring.

To select one of these options, use the [ ] [ ] keys

and press [ OK ].

IMPORTANT: On some vehicles with a standard OBD2 or

EOBD port, the diagnostic function may be disabled, or the

connection standard may be different from a commonly used

standard, so it will be impossible to connect to the injection

control unit. In this case, “Connection failed” will appear on

the display.

If this occurs, contact A.E.B. Technical Assistance.

1.5 Identifying the type of connection and the type

of OBD2 μFIX Emulator

The possible connections and corresponding Emulators are:

• Connection type 1 (ISO9141):

if the front oxygen sensor is a 4-wire type,

use emulator AEB426; if the front oxygen sensor is a 5-wire type (e.g.

Volkswagen) use emulator AEB425.

• Connection type 2 (KWP-2000 Fast Init): use emulator AEB426.

• Connection type 3 (KWP-2000 Slow Init): use emulator AEB426.

• Connection type 4 (SAE J1850 PWM): use emulator AEB424.

• Connection type 5 (

SAE J1850 VPW

): use emulator AEB424.

• Connection type 6 (CAN Standard 250 kbps): use emulator AEB428.

• Connection type 7 (CAN Extended 250 kbps): use emulator AEB428.

• Connection type 8 (CAN Standard 500 kbps): use emulator AEB428.

• Connection type 9 (CAN Extended 500 kbps): use emulator AEB428.

IMPORTANT: the electrical connections to the emulator may

vary with the type of vehicle being serviced. We recommend

you follow the installation instructions provided with the

emulator.

Contact A.E.B. Technical Assistance,

if necessary.

Fig. 2

OBD Scan Tool v.xxx

English

---------------------------------------

Please turn ignition key to ON

[ ] for help

[OK] to continue

Fig. 3

Connection type

2

----------------------------------

KWP-2000 Fast Init

----------------------------------

Fig. 4

KWP-2000 Fast Init

---------------------------------------

Parameters

Trouble Codes (DTC)

Freeze Frame

Latent Trouble Codes

Clear Trouble Codes

[ ] for help

Fig. 1

OBD Scan Tool v.X.XX

1. GENERAL DESCRIPTION

616000191_ENG Rev. 111114-0 5 - 12

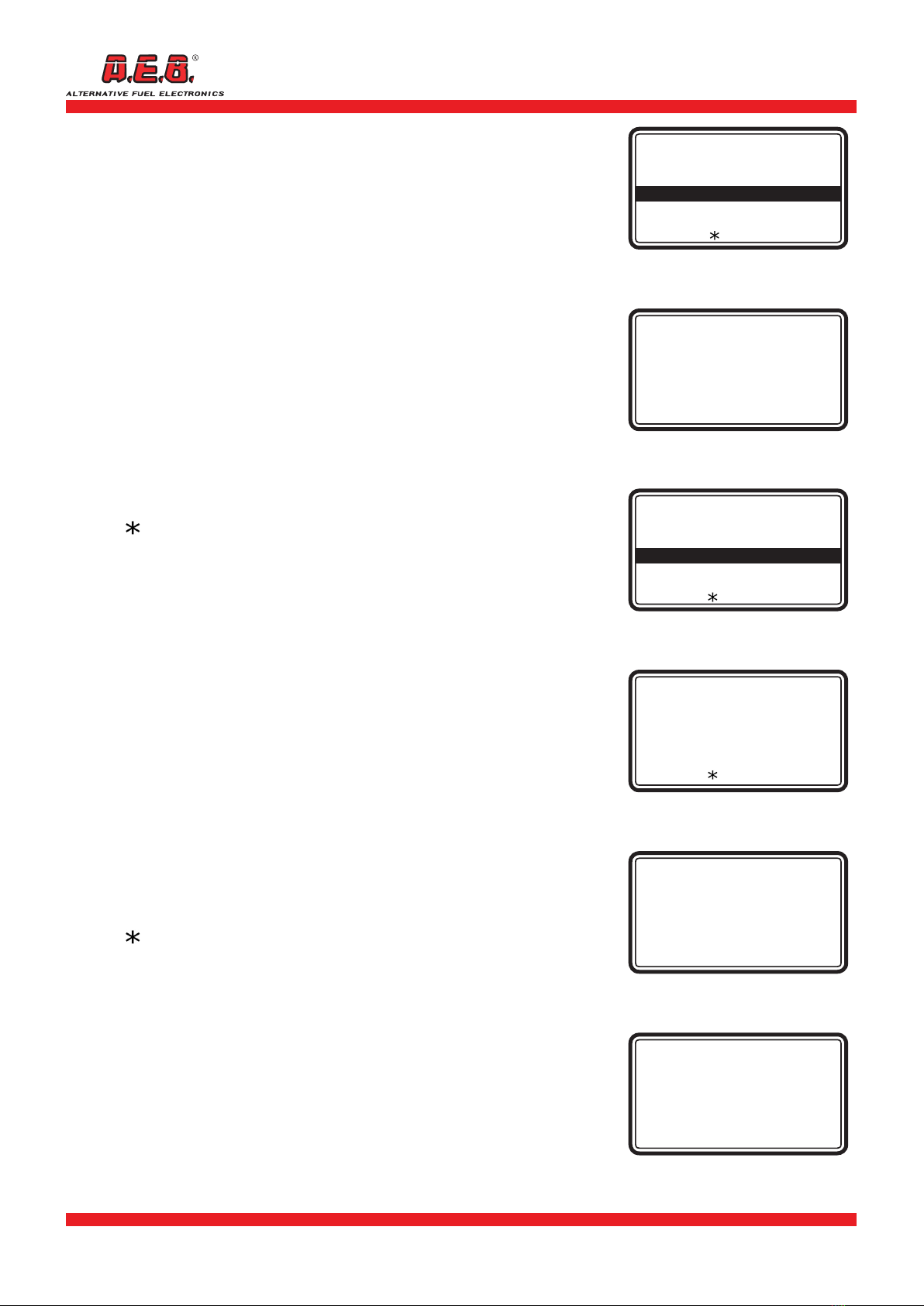

2.1 Parameters

This option is used to display certain vehicle operation parameters (e.g.

engine RPM, T.P.S., oxygen sensors etc.).

A list of available parameters is displayed when the option is rst

selected (Fig. 5). Use the [ ] [ ] keys to move the cursor [ » ] to

the desired parameter (Fig. 5) and select it by pressing the [ S ] key.

Selected parameters are shown in white against a black background

(Fig. 6).

Press [ OK ] to display all the selected parameters in the order of their

selection (Fig. 7).

To deselect a previously selected parameter, move

the cursor [ » ] to the desired parameter and press [ C ].

The display window (Fig. 7) can show 3 parameters at any one time.

If more parameters are selected, use the [ ] [ ] keys to scroll

through the parameters one at a time and use the [ ] [ ] keys to

move to the next 3 selected parameters.

Press [S] to display a list of codes for the control units in the vehicle.

Press [C] to display a map of the PIDs (Parameter Identication Codes)

handled by the control units in MODE 1. If there are a number of

control units, press

] [] to display them

.

Press [ ] to display the help screen.

IMPORTANT: the list of available parameters may vary with

the type of vehicle being serviced, so parameters previously

displayed for other vehicles may not be available on certain

vehicles.

2.2 Trouble codes (DTC)

This option is used to check whether the injection control unit has

errors stored in memory, and is also used to clear them.

To select this option, use the [ ] [ ] keys "Trouble Codes

(DTC)” (Fig. 8) and then press [ OK ]. If no errors are present, the

display will show “No trouble codes”.

If errors are present in memory, they will be displayed one at a time

(Fig. 9). The display will show the error code, the code of the ECU that

has detected the error and a description of the error.

The index number of the current error out of the total number of

errors appears next to “Trouble code” (e.g. the number 1/4 in g.

9 indicates that there are 4 errors in memory and the one currently

displayed is rst on the error list).

Use the [ ] [ ] keys to move to the next errors on the list.

If the description is very long, press [ ] [ ] to scroll through the

text on the display.

Press [S] to display the list of codes for the control units in the

vehicle.

Press [ ] to display the help screen.

To clear the errors from memory, press [ C ], which will bring up the

“Clear Trouble Codes” page (Fig. 10).

Press [ OK ] to clear the errors stored in the control unit (Fig. 11).

Pressing [ ESC ] the system will return to the previous page.

IMPORTANT: some vehicles do not allow errors to be cleared

while the engine is running.

If the same errors are still present after they have been

cleared, they must be cleared when the engine is not running

and the ignition is on.

Fig. 5

Parameter selection

---------------------------------------

Trouble Codes (DTC)

MI status

»Slow fuel trim 1

Fast fuel trim 1

Cylinder bank 1 status

Manifold pressure

Fig. 6

Parameter selection

---------------------------------------

Cylinder bank 1 status

Manifold pressure

Timing advance

Throttle opening

»Engine RPM

Vehicle speed

Fig. 7

Cylinder bank 1 status

Closed loop

---------

Manifold pressure

100 kPa

---------

Throttle opening

13.7%

Fig. 8

KWP-2000 Fast Init

---------------------------------------

Parameters

Trouble Codes (DTC)

Freeze Frame

Latent Trouble Codes

Clear Trouble Codes

[ ] for help

Fig. 9

Trouble code 1/4

---------------------------------------

P0133 ECU 10:

Slow O2 sensor response

(Bank 1 Sensor 1)

[ ] for help

Fig. 10

Clear Trouble Codes

---------------------------------------

[OK] to clear

[ESC] to cancel

Fig. 11

Clear Trouble Codes

---------------------------------------

Clearing

completed

2. MENUS

616000191_ENG Rev. 111114-0

6 - 12

2.3 Freeze frame

This option is used to display the vehicle operating parameters at the

moment when the injection control unit stores

an error in its memory.

To access this option, use the [ ] [ ] keys to select “Freeze

frame” (Fig. 12) and press [ OK ]. If no errors are stored in memory,

the display will show the following: “No trouble code”.

However, if one or more errors are stored in control unit memory, the

system will display the vehicle operating parameters (Fig. 13) that

were stored at the moment when the error occurred.

The frozen data provided by the injection control unit refer to

the rst error detected, only.

Three parameters at a time are displayed on the page. To scroll

through the next parameters one at a time, use the [ ] [ ] keys.

To move to the next set of three parameters, use the [ ] [ ] keys.

Press [ ESC ] to return to the main menu.

Press [C] to display a description of the error.

Press [S] to display a map of PIDs in MODE 2.

Press [ OK ] to display any other errors found.

Press [ ] to display the help screen.

2.4 Latent Trouble Codes

This option is used to check whether the injection control unit has

stored any errors but has not yet lit up the diagnosis indicator light,

and can also be used to clear the errors.

To access this option, use the [ ] [ ] keys to select “Latent

Trouble Codes” (Fig. 14) and then press [ OK ]. If no errors are

present, the display will show “No trouble codes”.

If errors are present in memory, they will be displayed one at a time

(Fig. 15). The display will show the error code, the code of the ECU

that has detected the error and a description of the error.

The index number of the current error out of the total number of

errors appears next to “Trouble code” (e.g. the number 1/4 shown

in g. 15 indicates that there are 4 errors in memory and the one

currently displayed is rst on the error list).

Use the [ ] [ ] keys to move to the next errors on the list.

If the description is very long, press [ ] [ ] to scroll through the

text on the display.

Press [S] to display the list of codes for the control units in the

vehicle.

Press [ ] to display the help screen.

To clear the errors from the memory, press [ C ], which will bring up

the "Clear Trouble Codes" page (Fig. 16).

Press [ OK ] to clear the errors stored in the control unit (Fig. 17).

Pressing [ ESC ] the system will return to the previous page.

IMPORTANT: some vehicles do not allow

errors to be cleared while the engine is running.

If the same errors are still present after they have been

cleared, they must be cleared when the engine is not

running and the ignition is on.

Fig. 12

KWP-2000 Fast Init

---------------------------------------

Parameters

Trouble Codes (DTC)

Freeze Frame

Latent Trouble Codes

Clear Trouble Codes

[ ] for help

Fig. 13

Freeze Frame

Frame 1

-------

Trouble code

P0133

-------

Slow fuel trim 1

15.6%

Fig. 14

KWP-2000 Fast Init

---------------------------------------

Trouble Codes (DTC)

Freeze Frame

Latent Trouble Codes

Clear Trouble Codes

Vehicle data

[ ] for help

Fig. 15

Trouble code 1/4

---------------------------------------

P0133 ECU 10:

Slow O2 sensor response

(Bank 1 Sensor 1)

[ ] for help

Fig. 16

Clear Trouble Codes

---------------------------------------

[OK] to clear

[ESC] to cancel

Fig. 17

Clear Trouble Codes

---------------------------------------

Clearing

completed

2. MENUS

616000191_ENG Rev. 111114-0 7 - 12

2.5 Clear trouble codes

This option is used to clear the errors stored in the injection control

unit.

Using the [ ] [ ] keys, select “Clear trouble codes” (Fig. 18)

and

press [ OK ] to bring up the “

Clear trouble codes

”page (Fig. 19).

Press [ OK ] to clear the errors stored in the control unit (Fig. 20).

IMPORTANT: all Trouble Codes will be cleared, except for

permanent codes.

Press the [ESC] key to return to the previous page.

Press [ ] to display the help screen.

IMPORTANT: some vehicles do not allow

errors to be cleared while the engine is running.

If the same errors are still present after they have been

cleared, they must be cleared when the engine is not

running and the ignition is on.

2.6 Permanent Trouble Codes

This option is used to display trouble codes that cannot be cleared by

the user. They are cleared automatically by the ECU (control unit)

when the problem is corrected.

Using the [ ] [ ] keys, select “Permanent Trouble Codes”

(Fig.21) and press [ OK ]. If this function is not available, “Not

managed” will appear on the display.

To scroll through the parameters on the display, use the [ ] [ ]

keys. Press [ ESC ] to return to the main menu.

Use the [ ] [ ] keys to move to the next errors on the list.

If the description is very long, press [ ] [ ] to scroll through the

text on the display.

Press [S] to display the list of codes for the control units in the

vehicle.

Press [ ] to display the help screen.

2.7 Vehicle Data

This option is used to display identifying information for the vehicle.

Using the [ ] [ ] keys, select “Vehicle Data” (Fig. 22) and press

[OK ]. If this function is not available, “Not managed” will appear

on the display. If it is available, the corresponding page will appear

(Fig. 23).

To scroll through the parameters on the display, use the [ ] [ ]

keys.

If the description is very long, press [ ] [ ] to scroll through the

text on the display.

Press [ESC ] to return to the main menu.

Press [ ] to display the help screen.

IMPORTANT: the list of available parameters may vary with

the type of vehicle being serviced, so parameters previously

displayed for other vehicles may not be available on certain

vehicles.

Fig. 18

KWP-2000 Fast Init

---------------------------------------

Freeze Frame

Latent Trouble Codes

Clear Trouble Codes

Permanent Trouble Codes

Vehicle data

[ ] for help

Fig. 19

Clear Trouble Codes

---------------------------------------

[OK] to clear

[ESC] to cancel

Fig. 20

Clear Trouble Codes

---------------------------------------

Clearing

completed

Fig. 22

KWP-2000 Fast Init

---------------------------------------

Clear Trouble Codes

Permanent Trouble Codes

Vehicle data

O2 sensor monitoring

Component monitoring

[ ] for help

Fig. 21

KWP-2000 Fast Init

---------------------------------------

Latent Trouble Codes

Clear Trouble Codes

Permanent Trouble Codes

Vehicle data 02

Sensor Monitoring

[ ] for help

Fig. 23

Vehicle identication

number

---------------------------------------

1G1J5444R7252367

2. MENUS

616000191_ENG Rev. 111114-0

8 - 12

2.8 O2 Sensor Monitoring

This option is used to display the operating parameters of

the oxygen sensors on the vehicle.

Using the [ ] [ ] keys, select “O2 Sensor monitoring” (Fig. 24)

and press [ OK ]. If this function is not available, “Not managed”

will appear on the display. If it is available, the corresponding page

will appear (Fig. 25). The display will show the value of the parameter

and its limits. To scroll through the next parameters, use the []

[] keys. To move to the parameters of the next oxygen sensor (if

present), use the [ ] [ ] keys.

Press [S] to display the list of codes for the control units in the vehicle.

Press [C] to display a map of the PIDs handled by the control units

in MODE 5 (, if available).

Press [ESC ] to return to the main menu.

Press [ ] to display the help screen.

2.9 Component Monitoring

This option is used to display certain operating parameters

of the components on the vehicle.

Using the [ ] [ ] keys, select “Component monitoring” (Fig.

26) and press [ OK ].

If this function is not available, “Not managed”will appear on the

display. If it is available, the corresponding page will appear (Fig. 27).

To scroll through the parameters displayed for a component, use the

[ ] [ ] keys. To display other components, press the [ ] [ ]

keys.

Press [

ESC ] to return to the main menu.

Press [S] to display the list of codes for the control units in the vehicle.

Press [C] to display a map of the PIDs handled by the control units in

MODE 6 (if available).

Press [ ] to display the help screen.

NOTE: to identify the type of component and the meaning

of the parameter displayed, see the manual supplied by the

manufacturer of the vehicle.

IMPORTANT: the list of available parameters may vary with

the type of vehicle being serviced, so parameters previously

displayed for other vehicles may not be available on certain

vehicles.

2.10 Performance Tracking

This option is used to display certain parameters relating to

vehicle performance.

Using the [ ] [ ] keys, select “Performance Tracking” (Fig. 28)

and press [ OK ].

If this function is not available, “Not managed” will appear on the

display. If it is available, the corresponding page will appear (Fig. 29).

To scroll through the parameters on the display, use the [

] [

] [

] [ ] keys

.

Press [ ESC ] to return to the main menu.

Press [S] or [C] to display the list of codes for the control units in the

vehicle. Press [ ] to display the help screen.

IMPORTANT: the list of available parameters may vary with

the type of vehicle being serviced, so parameters previously

displayed for other vehicles may not be available on certain

vehicles.

Fig. 26

KWP-2000 Fast Init

---------------------------------------

Clear Trouble Codes

Vehicle data

O2 sensor monitoring

Component monitoring

Performance analysis

[] for help

Fig. 27

Fall time

Component 5

---------------------------------------

250

-------

Allowed values

X >= 50

Fig. 28

KWP-2000 Fast Init

---------------------------------------

Clear Trouble Codes

Vehicle data

O2 sensor monitoring

Component monitoring

Performance tracking

[ ] for help

Fig. 29

Performance tracking

---------------------------------------

OBD tests performed

1024

--------

Ignition counter

3337

Fig. 24

KWP-2000 Fast Init

---------------------------------------

Clear Trouble Codes

Vehicle data

O2 sensor monitoring

Component monitoring

Performance tracking

[ ] for help

Fig. 25

O2 sensor monitoring

O2 sensor 1 bank 1

---------------------------------------

Minimum voltage

0.050 V

-------

Allowed values

0.000 V ÷ 1.000 V

2. MENUS

616000191_ENG Rev. 111114-0 9 - 12

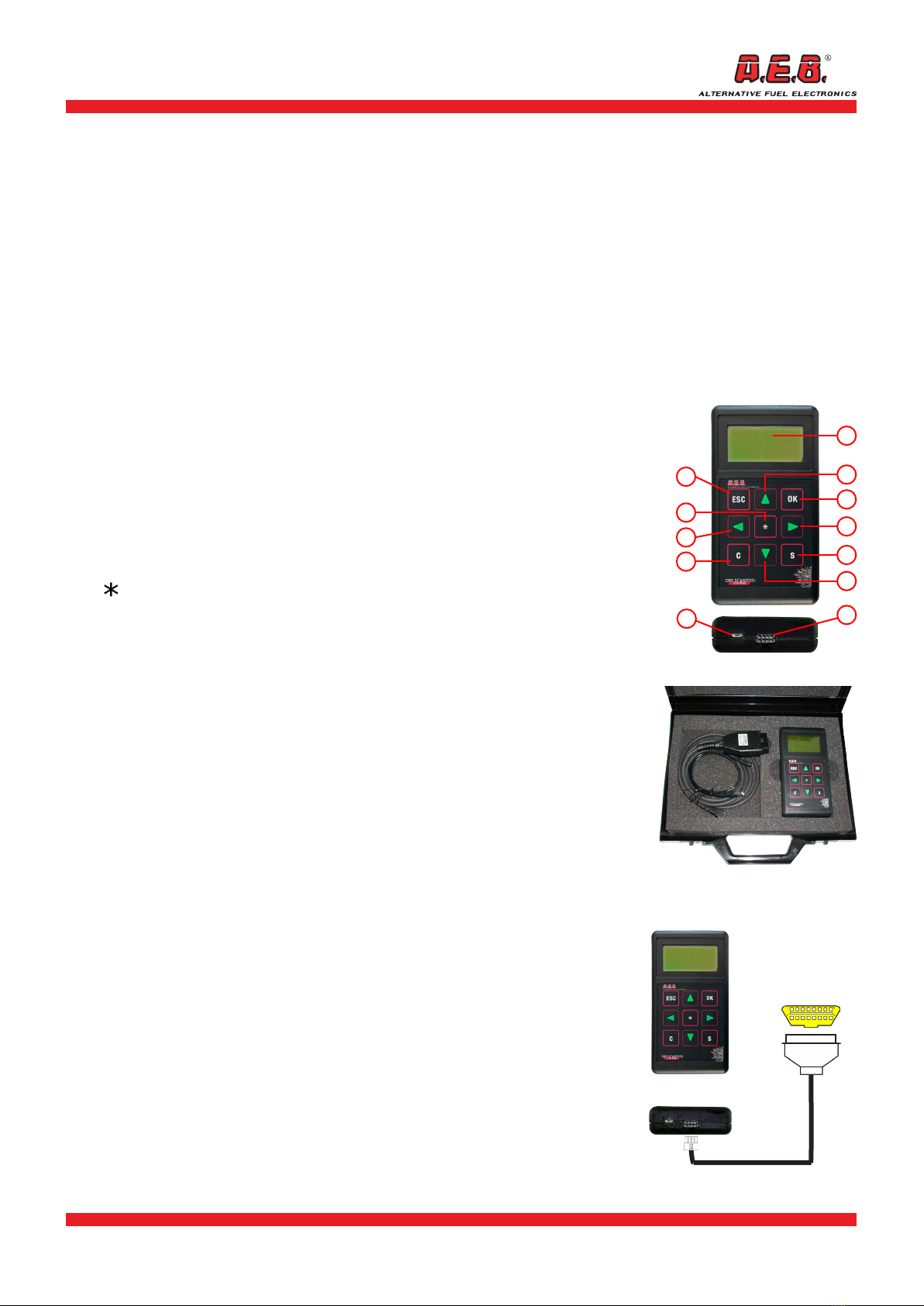

The Tester can be reprogrammed and updated with a PC and the USB cable supplied in the package,

and with dedicated SW.

USB PC-TESTER

CONNECTING

CABLE

PERSONAL

COMPUTER

OBD AEB214 PLUS

TESTER

1) Click on a ag to change the language setting for the programming software.

2) "Start programming OBD tester" button. The computer does not have to be connected to the Internet

while the tester is programmed.

3) Firmware version.

4) Program exit button.

Download the software at http://www.aeb.it, “Products” menu, “Sundry Items” category, “Diagnostic

tools”, “AEB214PLUS”, “download software”.

After the “OBDScanTool” software has been installed on your PC, the icon shown to the side will appear

on the display . Double-click on the icon to run the software for programming the OBD Tester.

3.2 UPDATING/REPROGRAMMING PROCEDURE

234

1

3.1 CONNECTION FOR REPROGRAMMING/UPDATING

Fig. 1

OBD Scan Tool v.X.XX

USB

Switching on the Tester

The AEB214 PLUS Tester switches on automatically when it is

connected to the USB port on the PC using the cable provided.

When it switches on, the screen shown in Fig. 1 appears on

the display.

If necessary, press any key to select the desired language.

IMPORTANT:

When the tester is connected for the rst time, the

display may take several seconds to light up, because the

operating system on the PC must recognize the device

and load the required drivers.

3. PROGRAMMING AND UPDATING THE TESTER

616000191_ENG Rev. 111114-0

10 - 12

3.3 FEATURES OF THE AEB214 PLUS TESTER

The following new features were added with rmware “Version 7.00”:

• Adjustment of display brightness and contrast.

• Selection of 7 languages on the tester: Italian, English, German, French, Spanish, Turkish and

Czech.

• Readout of power supply voltage.

• Communication protocol selection menu.

• Increase in the number of PIDs handled

(Parameter IDs: parameter identication codes).

• Increased capability of handling very long strings in help messages and DTC descriptions

(scrolling).

• Improved response to abort command during connection.

• Extended times displayed in the h.mm'.ss" format.

• Modied DTC display in Mode 3.

3. PROGRAMMING AND UPDATING THE TESTER

616000191_ENG Rev. 111114-0 11 - 12

Dear Customer,

Thank you for the trust you have placed in A.E.B. by purchasing this product.

A.E.B. subjects all its products to stringent quality tests. If the product malfunctions despite the tests, we

recommend you immediately contact the installer for any checks or service calls that may be required.

- General conditions of warranty

A.E.B. guarantees that this product operates properly and is free from manufacturing defects.

If the product proves to be defective during the warranty period, A.E.B. will repair or replace it free of

charge. The work will be done by an individual or company that is designated by mutual agreement.

Defective parts will be replaced ex-works A.E.B., and the recipient will be responsible for shipping costs.

Accessories and components not made by A.E.B. are covered by their manufacturers’ warranties only.

This warranty is the only warranty offered by A.E.B. All others are excluded.

Except in case of malice or gross negligence, A.E.B. will not be held liable for any personal injury or

property damage caused by product malfunction. This warranty is valid only if the purchaser is up to

date with payments.

- Specic conditions

The warranty shall be valid for a period of 24 months starting from the date printed on the

product with indelible paint.

The warranty shall be valid only if the product is properly stored in its original A.E.B. packaging at the

time of purchase. The original packaging provides the sole guarantee that the product is genuine and

adequately protected.

- Exclusions

This warranty does not cover:

a) Periodic testing, maintenance, repairs, replacement of parts due to normal wear.

b) Malfunctions due to negligence, incorrect installation, improper use, failure to comply with technical

instructions and, in general, any malfunction not attributable to manufacturing defects of the product

and therefore not the responsibility of A.E.B.

c) Products that have been modied, repaired, replaced, installed or tampered with without the prior

written authorization of A.E.B.

d) Accidents caused by Acts of God or other causes (e.g. water, re, lightning, inadequate ventilation,

etc.) not attributable to A.E.B.

Products with manufacturing defects that can be recognised with normal diligence may not

be resold or installed.

Any disputes concerning the interpretation or execution of this warranty shall be settled

exclusively before the Court of Reggio Emilia, Italy.

4. CERTIFICATE OF WARRANTY

AEB Alternative Fuel Electronics

Via dell’Industria 20 42025 - Cavriago - Italy

Phone +39 0522 494401 - fax. +39 0522 494410

Technical assistance

Phone +39 0522 494414 - fax. +39 0522 494410

a division of

This manual suits for next models

1

Table of contents