2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

1�1 Key to the symbols � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 Documentation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

4 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

5 Sensor functions� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

5�1 Firmware � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�2 Description of functions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

6 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

6�1 Sources of interference � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

6�2 Cable routing in control cabinets� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

6�3 Installation instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

7 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

7�1 Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

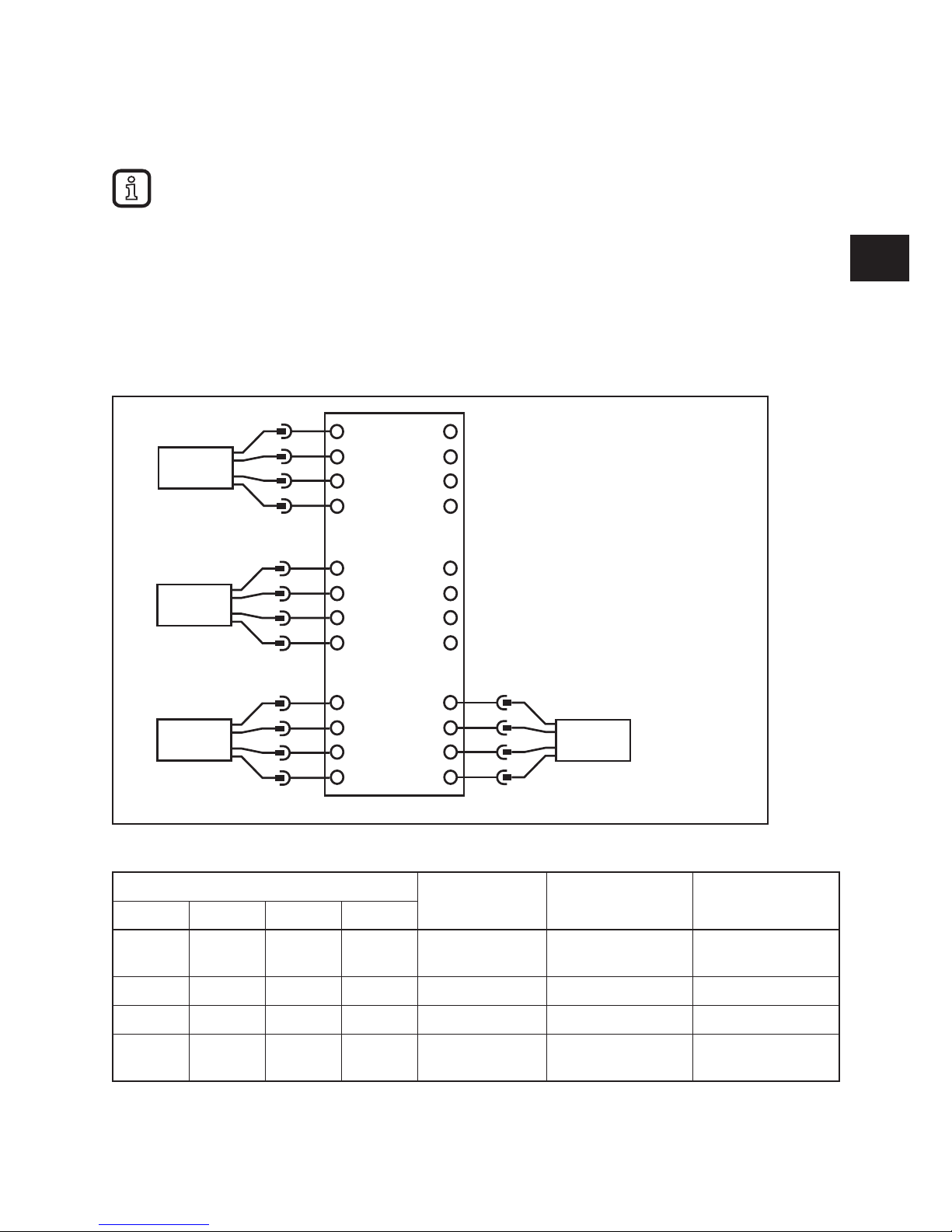

7�2 Connection of the sensors � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

7�3 Ethernet connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

8 EtherNet/IP � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

8�1 EtherNet/IP object classes, messages and services � � � � � � � � � � � � � � � � �11

8�2 EtherNet/IP data model � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

8�3 Supported communication types � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

8�4 CIP object classes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

8�4�1 Identity object (class code 0x01) � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

8�4�2 Message router object (class code 0x02) � � � � � � � � � � � � � � � � � � � � 16

8�4�3 Assembly object (class code 0x04) � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�4�4 Connection manager object (class code 0x06) � � � � � � � � � � � � � � � � 16

8�4�5 Device level ring object (class code 0x47)� � � � � � � � � � � � � � � � � � � � 17

8�4�6 Quality of service object (class code 0x48) � � � � � � � � � � � � � � � � � � � 18

8�4�7 TCP/IP object (class code 0xF5) � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

8�4�8 Ethernet link object (class code 0xF6) � � � � � � � � � � � � � � � � � � � � � � � 21

8�5 EtherNet/IP - assembly instances � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

8�6 EtherNet/IP - connection types� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

8�6�1 EtherNet/IP - defined connections in the Standard EDS File� � � � � � 24

8�7 Ethernet/IP functions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

8�7�1 Quality of Service (QoS) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�7�2 Device Level Ring (DLR) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�7�3 Address Conflict Detection (ACD) � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�8 EtherNet/IP properties � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�9 Behaviour if parameter set is changed� � � � � � � � � � � � � � � � � � � � � � � � � � � 26

9 Factory setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

9�1 General factory setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

9�2 Factory setting VSE151 - EtherNet/IP � � � � � � � � � � � � � � � � � � � � � � � � � � � 26