iii

INM F809F-Plus Rev 3

DRAFT - 02 March 2017 DRAFT - 02 March 2017

CONTENTS

DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv - v

1 OVERVIEW ........................................................................1

1.1 Components and accessories ..............................................................1

2 INSTALLATION .....................................................................2

2.1 Mounting ...............................................................................2

2.2 Power requirements......................................................................3

2.3 Configuration of fieldbus communication segment ............................................3

2.4 Installation for communication on separate fieldbus segment ...................................4

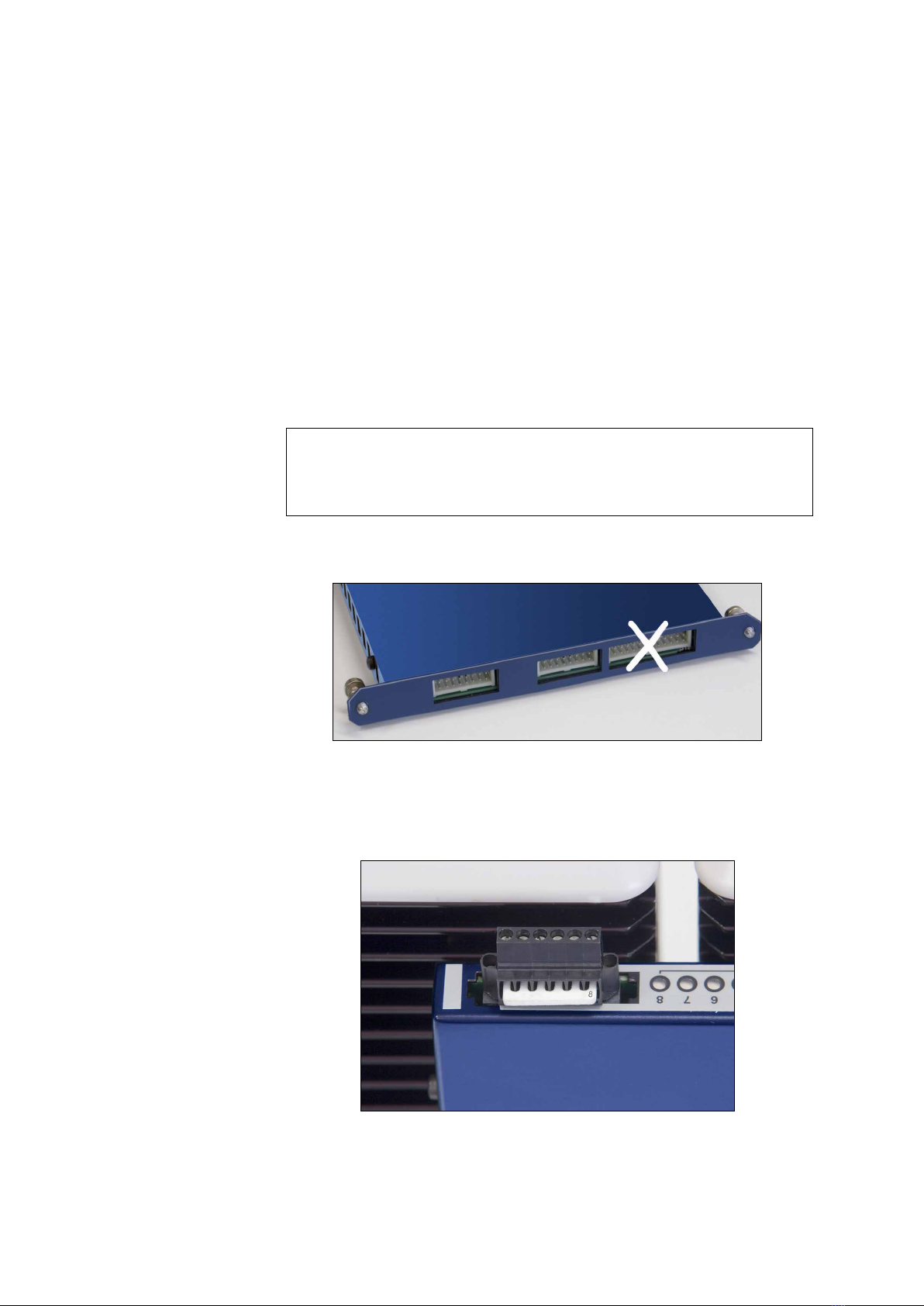

2.4.1 Interconnection via carrier ...............................................................4

2.4.2 Interconnection via top connector .........................................................5

2.4.3 Fieldbus segment design rules............................................................6

2.4.4 Diagnostics module power supply.........................................................6

2.4.5 Diagnostics module segment termination ..................................................6

2.5 Ground Reference Switches ...............................................................6

3 CONFIGURATION ...................................................................7

3.1 Standard ...............................................................................7

3.2 F809F-Plus Configuration..................................................................7

4 BLOCK CONFIGURATION ............................................................8

4.1 Resource Block .......................................................................8-10

4.1.1 Diagnostic Bits .....................................................................10-11

4.1.2 Block errors...........................................................................11

4.1.3 Modes ...............................................................................11

4.2 Transducer Blocks.......................................................................12

4.2.1 Transducer Block Errors ................................................................12

4.2.2 Transducer Block Modes ................................................................12

4.2.3 Transducer Block Alarm Detection ........................................................13

4.2.4 System Transducer Block (SysTB) .....................................................13-15

4.2.4.1 System alarms ...................................................................16

4.2.4.2 Self test alarms ..................................................................16

4.2.4.3 Methods ........................................................................17

4.2.5 Segment Transducer Block (SegTB)....................................................17-20

4.2.5.1 SEGMENT_ALARMS - Descriptions and Corrective Actions ...........................21-22

4.2.5.2 DEVICE_ALARMS - Descriptions and Corrective Actions ................................22

4.2.5.3 DEVICE_ALERTS - Descriptions .....................................................22

4.3 Discrete Input Block .....................................................................23

4.3.1 Discrete Input Block Errors ..............................................................23

5 OPERATION AND MAINTENANCE ....................................................24

5.1 LED indicators..........................................................................24

5.2 FOUNDATIONTM fieldbus Information .........................................................24

5.2.1 Commissioning (Addressing) ............................................................24

5.3 Hardware Maintenance ..................................................................24

5.3.1 Communication/Power Check............................................................24

5.3.2 Resetting the Configuration (RESTART)....................................................24

5.4 Troubleshooting ........................................................................25

5.4.1 FOUNDATIONTM fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4.2 Resource Block ........................................................................25

5.4.3 System and Segment Transducer Block Troubleshooting .....................................25

APPENDIX A: Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27